- Take great care when removing old seals that the sealing surfaces and seal housing are not damaged.

- Carefully examine seal before fitting to ensure that it is clean and undamaged.

- Ensure that the surface on which the seal is to run and also the seal housing is clean and free from burrs or scratches. Renew the component if the sealing surface cannot be restored.

- Special tools and protection sleeves are provided for fitting the majority of seals and must be used when specified.

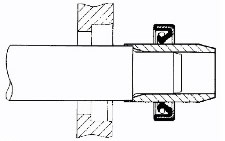

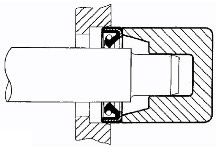

When fitting an oil seal, ensure that it is positioned square to shaft and housing. Where the seal is to be fitted to a housing prior to fitting over a shaft, take care not to allow the weight of an unsupported shaft to rest on the seal.

Press or drift the seal in to the depth of its housing if the housing is shouldered or flush with the face of the housing where no shoulder is provided. Ensure that the seal is not tilted in the housing when it is fitted.

Komentari na ovaj članak