GENERAL INFORMATION, Precautions when working with electrical equipment.

Performing a procedure

1. Disconnect "mass" battery wire.

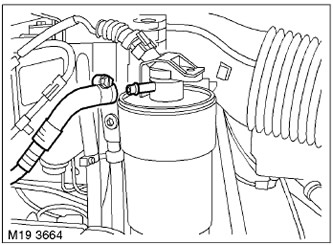

2. Take a piece of clean rag and place it in the engine compartment so that it can absorb the fuel spilled during the disconnection of the pipelines.

3. Loosen the clamp on the fuel filter outlet hose and remove the corresponding fuel hose.

CAUTION: Before disconnecting any part of the fuel system, thoroughly clean the surrounding area of dirt, dust and deposits to prevent foreign particles from entering the system.

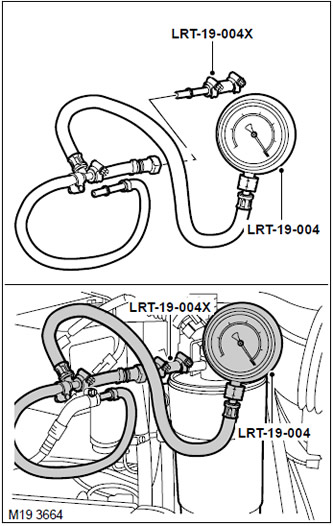

4. Insert fitting LRT-19-004 into fuel filter outlet hose and secure with clamp.

5. Insert the fitting into the detachable connection, put a short hose on the fitting and secure it with a clamp.

6. Put a short hose on the fuel filter fitting and secure with a clamp.

7. Make sure that the fuel hoses are securely connected and cover the location of the fuel filter with a rag.

8. Connect "mass" battery wire.

9. Insert the key into the ignition switch and turn it to position II.

10. Holding the key in position II, record the pressure gauge readings. If the pressure is below the set value (3.5 bar±0.1 bar, at battery voltage 11.5 volts±0.1 volts, at 200°C±50°C), replace the additional fuel pump.

11. Turn off the ignition and remove the key from the lock.

12. Disconnect "mass" battery wire.

13. Take a piece of clean rag and place it in the engine compartment so that it can absorb the fuel spilled during the disconnection of the pipelines.

14. When the pressure gauge needle approaches zero on the scale, you can disconnect the device from the fuel system.

15. Put the outlet hose on the fuel filter fitting and secure with a clamp.

16. Connect "mass" battery wire.

17. Start the engine, check for leaks from the fuel filter and hoses.

18. Stop the engine.

19. Disconnect short hose fitting from LRT-19-004.

Comments on this article