Disassembly

1. Remove the 2 exhaust camshaft chain tensioner mounting nuts, remove the tensioner and discard the O-ring.

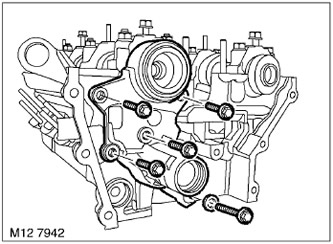

2. Turn away 5 bolts of fastening of the case of a small distributor of a regulator of phases of gas distribution. Remove the sealing washer from the long bolt and discard it.

3. Remove the oil distributor housing, remove and discard the gasket.

NOTE: If the oil distributor is worn, then free it from the sealing rings by moving it back and forth.

4. Carefully separate and remove from the inlet camshaft 3 O-rings of the RFG oil distributor.

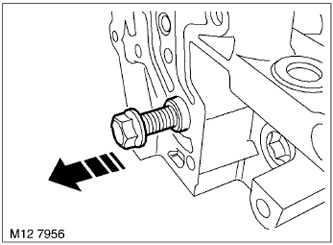

5. Screw the M10 bolt into the RFG check valve and, pulling by hand, remove the valve from the cylinder head. Dispose of the O-ring.

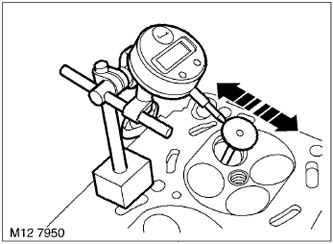

6. Check the camshaft end play using a dial gauge.

TECHNICAL DATA, Engine - V8.

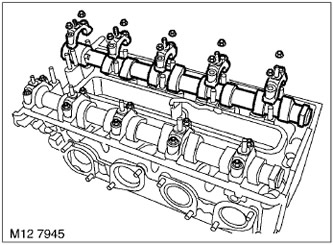

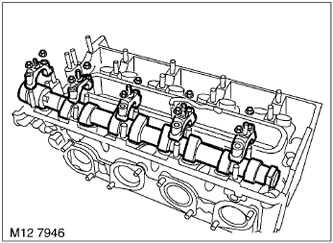

7. Using the hexagon wrench, rotate the intake camshaft until the tops of the cams of the 8th cylinder are facing up.

8. Using the hexagon wrench, rotate the exhaust camshaft until the tops of the cams of the 6th cylinder are facing up.

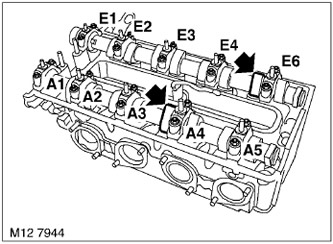

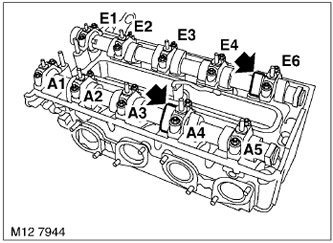

9. Pay attention to how the camshaft bearing caps are marked. The intake camshaft is marked with a letter "E", and its covers are designated from "E1" before "E5" from the front (slave) end of the camshaft as viewed from the intake side. Exhaust camshaft marked with letter "A", and its covers are designated from "A1" before "A5" from the front (slave) end of the camshaft as viewed from the intake side.

10. Loosen and remove the 10 intake camshaft cap nuts evenly and sequentially.

11. Remove the camshaft covers.

12. Remove the intake camshaft.

13. Loosen and remove the 10 exhaust camshaft cap nuts evenly and sequentially.

14. Remove the camshaft covers.

15. Remove the final camshaft.

16. Remove the hydraulic compensators. If they are to be reused, arrange them in the order in which they were installed.

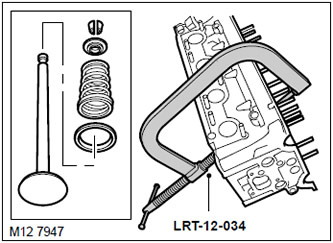

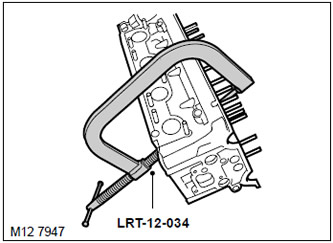

17. Install the LRT-12-034 cracker on the valve disc and compress the valve spring

18. Take out 2 crackers and remove the cracker.

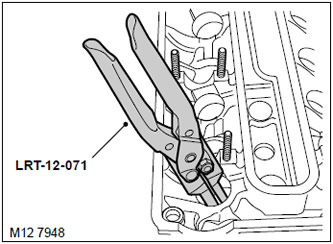

19. Remove the valve stem seals using the LRT-12-071 pliers. Dispose of the caps.

20. Do the same on the remaining valves, laying out the removed parts in the order in which they were on the cylinder head.

Examination

1. Check the condition of the camshafts. If they are scratched, dented, or excessively worn, replace the camshafts.

TECHNICAL DATA, Engine - V8.

2. Check up degree of wear of necks and beds of cam-shafts.

TECHNICAL DATA, Engine - V8.

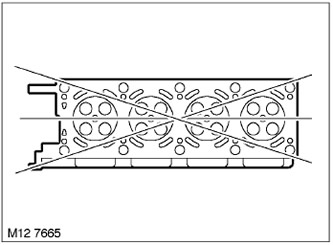

3. Using a straightedge and a feeler gauge, check the deformation of the bottom plane of the head in the directions shown in the figure.

TECHNICAL DATA, Engine - V8.

4. Check the condition of the valve seats for gouges, burns, cracks and wear.

5. Insert the new valve into the guide so that the top of the valve stem is on the cut of the guide sleeve.

6. Install a pointer indicator on the cylinder head and set "zero" indicator, resting its leg on the valve plate. By shaking the valve sideways, determine the degree of wear of the valve guide.

TECHNICAL DATA, Engine - V8.

7. If the movement of the valve in the sleeve is too large, then you need to turn the hole in the sleeve for valves with an increased stem diameter.

TECHNICAL DATA, Engine - V8.

8. After the sleeves have been deployed for valves with an increased diameter of the stem, it is necessary to dress the seats using the special tool LRT-12-501, LRT-12-503 and LRT-12-517.

TECHNICAL DATA, Engine - V8.

9. Make sure that the cutters are in the correct position in the cutting head. The cutters must cut the bevel of the seat with their middle part. Do not apply heavy cutting force and remove the minimum amount of material from the seat.

10. If necessary, repeat these operations on the remaining valves, valve guides and valve seats.

11. Check the degree of wear of the VCC oil distributor housing and sealing rings.

TECHNICAL DATA, Engine - V8.

ATTENTION: Replace the body and rings if there are obvious gouges and scuffs in the longitudinal direction.

Assembly

1. Remove carbon deposits from guide bushings and inlet passages, blow with compressed air.

2. Wipe the valves, valve springs, upper and lower spring plates and croutons.

3. Lubricate the valve with clean engine oil and insert it into the guide.

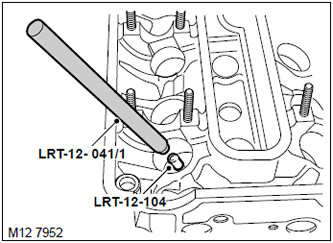

4. Put the LRT-12-104 protective boot on the stem, put the oil scraper cap on the valve and remove the LRT-12-104 boot. Press the cap onto the guide sleeve using the LRT-12-041/1 tool.

5. Put the lower plates into the head, put on the valve springs the upper plates.

6. Use the LRT-12-034 dryer to compress the valve spring. Put on crackers and carefully release the spring.

7. Do the same for the remaining valves.

8. Wipe tappets, pusher beds, make sure that the oil channels are clean.

9. Grease pushers and their beds and insert pushers on their former places.

10. Wipe the camshafts.

11. Wipe the beds of the camshafts. Make sure the oil passages are clean.

12. Lubricate the camshaft, its beds and covers.

13. Install the exhaust camshaft with the tops of the cams of the 6th cylinder up. Install in the correct order the caps with the letter "A", evenly and consistently tighten the nuts to 14 Nm.

14. Install the intake camshaft with the tops of the cams of the 8th cylinder up. Install in the correct order the caps with the letter "E", evenly and consistently tighten the nuts to 14 Nm.

15. Wipe the VCC oil check valve, make sure the oil passages are clean.

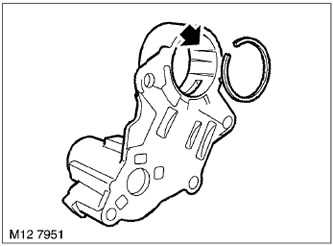

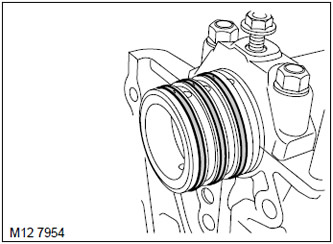

16. Insert the VCC oil check valve into the cylinder head using a new O-ring.

CAUTION: The VCC check valve must be installed so that the M10 thread remains visible.

17. Wipe the VCC oil distribution rings and grooves on the intake camshaft journal.

18. Lubricate the oil distribution rings and carefully install them into the grooves of the intake camshaft.

19. Wipe the mating surfaces of the VCC oil distributor housing and cylinder head. Make sure the oil passages are clean.

20. Install the VCC oil distributor housing gasket on the cylinder head.

21. Establish all VCC rings gaps up, put on them the case and establish it on a head of cylinders.

22. Put a new sealing washer on the long bolt and tighten the VCC housing mounting bolts to 10 Nm.

23. Wipe the exhaust camshaft chain tensioner and mating surface. Make sure the oil passage is clean.

24. Lubricate the exhaust camshaft chain tensioner.

25. Install the exhaust camshaft chain tensioner with a new O-ring and tighten the bolts to 10 Nm.

26. Wipe the exhaust manifold and mating surface on the cylinder head.

27. Install the exhaust manifold to the cylinder head using new gaskets.

28. Screw nuts of fastening of a final collector and tighten them. Tightening torque 24 Nm.

Comments on this article