GENERAL INFORMATION, Precautions when working with electrical equipment.

Dismantling

1. Put the car on a lift.

2. Disconnect "negative" battery terminal.

3. Drain the engine coolant.

COOLING SYSTEM: V8 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

4. Remove the fan guard.

COOLING SYSTEM: V8 engine, REPAIR WORK, Viscous fan clutch.

5. Remove the valve cover of the left cylinder head.

V8 engine, REPAIR WORK, Left cylinder head valve cover gasket.

6. Remove the valve cover of the right cylinder head.

V8 engine, REPAIR WORK, Right cylinder head valve cover gasket.

7. Remove 8 spark plugs.

8. Turn away 2 bolts of fastening of a back lifting eye on the right head of cylinders and remove an eye.

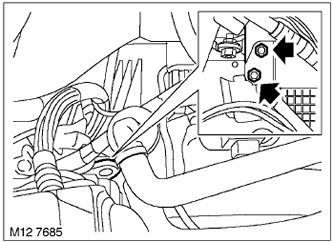

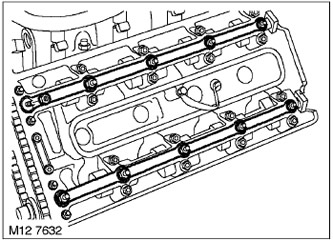

9. Turn away 20 nuts of fastening of 4 oil distribution tubes of greasing of camshafts of the left and right heads of cylinders and remove oil distribution tubes.

10. Turn the crankshaft so that the camshaft cams on the first cylinder are in the T.M.T position of the start of the working cycle.

11. The rear of the camshaft may appear to be misaligned and misaligned with cylinder #1 cams at T.M.T. start of the working cycle.

NOTE: The seemingly incorrect position of the camshafts does not indicate incorrect valve timing.

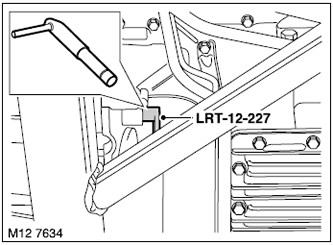

12. Insert pin LRT-12-227 through hatch and lock flywheel in T.M.T.

13. Remove the upper front cover of the timing mechanism drive on the left head.

V8 engine, REPAIR WORKS, Upper front timing cover of the left cylinder head.

14. Remove the upper front cover of the timing mechanism drive on the right head.

V8 engine, REPAIR WORKS, Upper front timing cover of the right cylinder head.

15. Turn away a nut of fastening of a disk of the sensor of position of a cam-shaft of the left head and remove a disk.

NOTE: This thread is left handed.

16. Turn away a nut of fastening of a disk of the sensor of position of a cam-shaft of the right head and remove a disk.

NOTE: This thread is left handed.

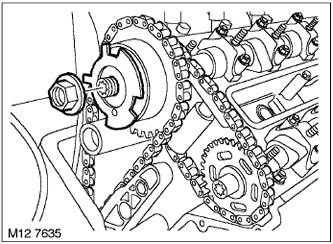

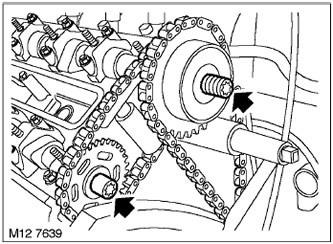

17. Loosen the 2 left head VCC bolts and the left head exhaust camshaft sprocket by half a turn.

NOTE: This thread is left handed.

18. Loosen the 2 bolts securing the right head VCC and the right head exhaust camshaft sprocket by half a turn.

NOTE: This thread is left handed.

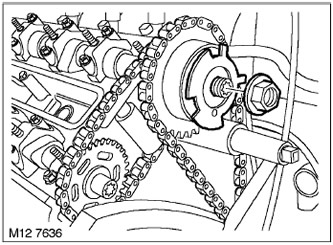

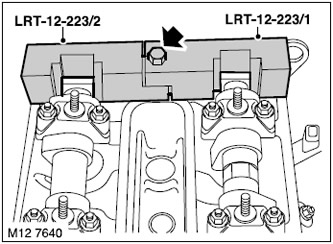

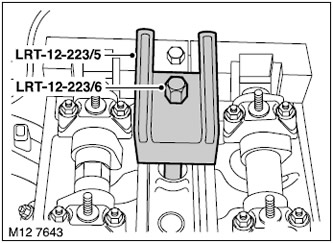

19. Loosen the bolt securing the mandrel LRT-12-223/2 to the mandrel LRT-12-223/1.

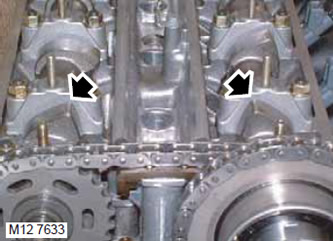

20. Install mandrels LRT-12-223/2 and LRT-12-223/1 on the rear of the right cylinder head camshafts and tighten the bolt.

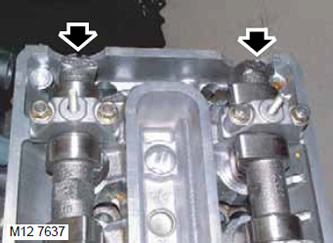

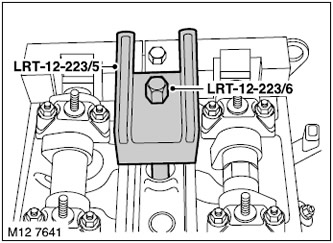

21. Install mandrels LRT-12-223/5 and LRT-12-223/6 on the right cylinder head and tighten mandrel LRT-12-223/6 using the threaded socket of the spark plug.

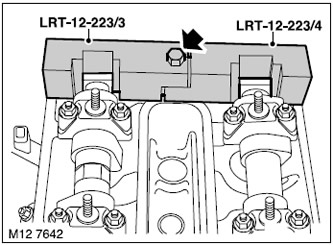

22. Loosen the bolt securing the mandrel LRT-12-223/4 to the mandrel LRT-12-223/3.

23. Install mandrels LRT-12-223/4 and LRT-12-223/3 on the rear of the camshafts of the left cylinder head and tighten the bolt.

24. Install mandrels LRT-12-223/5 and LRT-12-223/6 on the left cylinder head and tighten LRT-12-223/6 using the threaded socket of the spark plug.

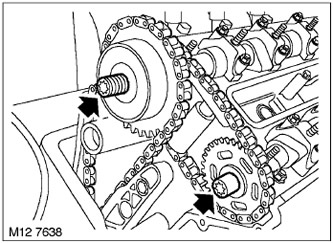

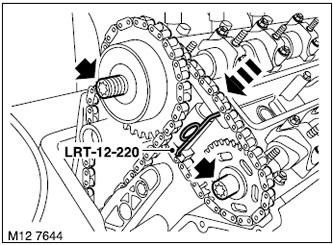

25. Compress the left head exhaust chain tensioner spring, insert the LRT-12-220 pin into the tensioner and remove the 2 bolts securing the VCC and exhaust camshaft sprockets.

NOTE: This thread is left handed.

26. Remove the exhaust camshaft sprocket, exhaust drive chain and left head VCC.

NOTE: To prevent the chain from falling down, attach it to the cylinder head.

Assembly

1. Put the exhaust camshaft chain on the left head VCC block, insert the exhaust camshaft sprocket into the drive chain.

NOTE: The VCC block, exhaust camshaft timing chain, and exhaust camshaft sprocket have no timing marks. These components can be mounted on the drive chain and on the camshafts in any position.

2. Putting the drive chain on the VCC block, install the VCC and the exhaust camshaft sprocket on their camshafts, screw in and tighten the 2 mounting bolts so that the play is eliminated. NOTE: This thread is left handed.

3. Compress the exhaust camshaft drive chain tensioner spring and remove pin LRT-12-220.

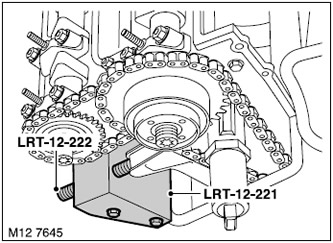

4. Install Drift LRT-12-221 on Right Cylinder Head, fasten Drift LRT-12-222 to LRT-12-221 and tighten by hand.

NOTE: Turn the adjusting bolt in only until there is slight resistance.

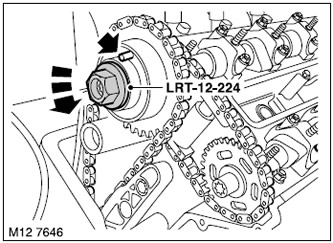

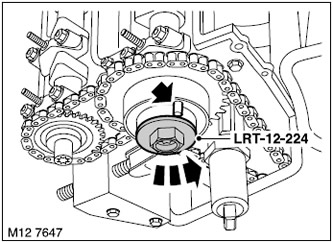

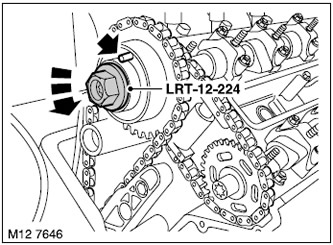

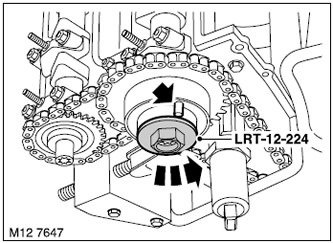

5. Install tool LRT-12-224 on the VCC of the left cylinder head and connect a tester between the pin on the VCC and the stud on the oil distribution tube.

6. Rotate the VCC block using the LRT-12-224 tool until the rotation force reaches 40 Nm, using a tester, check the continuity of the circuit.

NOTE: Turning the VCC on the LRT-12-224 removes excess oil and brings the VCC to its stop. The circuit is closed when VCC reaches the stop.

7. Tighten the left VCC and exhaust camshaft sprocket bolts to 15 Nm and loosen a quarter of a turn.

NOTE: This thread is left handed.

8. Install tool LRT-12-224 on the VCC of the right cylinder head and connect a tester between the pin on the VCC and the stud on the oil distribution tube.

9. Rotate the VCC block using the LRT-12-224 tool until the rotation force reaches 40 Nm, using a tester, check the continuity of the circuit.

NOTE: Turning the VCC on the LRT-12-224 removes excess oil and brings the VCC to its stop. The circuit is closed when VCC reaches the stop.

10. Tighten the right VCC mounting bolts and exhaust camshaft sprocket to 15 N» m and loosen a quarter of a turn.

NOTE: This thread is left handed.

11. Adjust chain tension by tightening tool LRT-12-222 to 0.7 Nm.

12. Install tool LRT-12-224 on the VCC of the left cylinder head and connect a tester between the pin on the VCC and the stud on the oil distribution tube.

NOTE: When adjusting the chain tension, the VCC is shifted, after which it is required to bring it to the left stop.

13. Turn the VCC on the LRT-12-224 tool until the rotation force reaches 40 Nm, using a tester, check the continuity of the circuit.

NOTE: Turning the VCC on the LRT-12-224 removes excess oil and brings the VCC to its stop. The circuit is closed when VCC reaches the stop.

14. Tighten the left VCC block bolts to 110 Nm, and the exhaust sprocket bolt to 125 Nm.

NOTE: This thread is left handed.

15. Install tool LRT-12-224 on the VCC of the right cylinder head and connect a tester between the pin on the VCC and the stud on the oil distribution tube.

NOTE: When adjusting the chain tension, the VCC is shifted, after which it is required to bring it to the left stop.

16. Rotate the VCC block using the LRT-12-224 tool until the rotation force reaches 40 Nm, using a tester, check the continuity of the circuit.

NOTE: Turning the VCC on the LRT-12-224 removes excess oil and brings the VCC to its stop. The circuit is closed when VCC reaches the stop.

17. Tighten the right VCC block bolts to 110 Nm, and the exhaust sprocket bolt to 125 Nm.

NOTE: This thread is left handed.

18. Install the camshaft position sensor disc and tighten the disc mounting nut by hand.

NOTE: This thread is left handed.

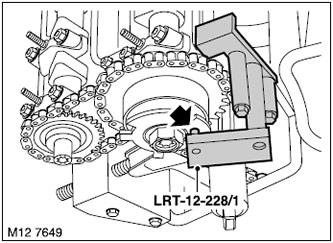

19. Install the LRT-12-228 / 1 retainer on the right camshaft position sensor disk, screw in the 2 bolts securing the retainer to the right cylinder head and tighten them.

NOTE: In order to properly adjust the position of the camshaft position sensor disk (CMP) before tightening the retainer bolts, make sure that the fixture fits snugly on the surface of the cylinder head and on the bottom of the engine front cover (timing cover).

20. Tighten the nut securing the camshaft position sensor disk to 40 Nm and remove the LRT-12-228/1 retainer from the right cylinder head.

NOTE: This thread is left handed.

21. Establish the left disk of the gauge of position of a camshaft and tighten by force of a hand a nut of fastening of a disk.

NOTE: This thread is left handed.

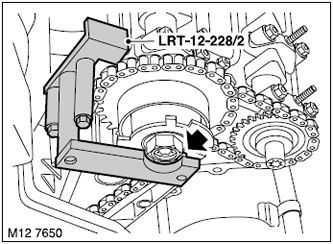

22. Install the LRT-12-228 / 2 retainer on the left camshaft position sensor disk, screw in the 2 bolts securing the retainer to the left cylinder head and tighten them.

NOTE: In order to properly adjust the position of the camshaft position sensor disc, before tightening the retainer mounting bolts, make sure that the tool is firmly seated on the surface of the cylinder head and on the bottom of the engine front cover (timing cover).

23. Tighten the camshaft position sensor disk mounting nut to 40 Nm and remove the LRT-12-228/2 retainer from the left cylinder head.

NOTE: This thread is left handed.

24. Remove the LRT-12-223/6, LRT-12-223/5, LRT-12-223/2 and LRT-12-223/1 tools from the right cylinder head camshafts.

25. Remove the LRT-12-223/6, LRT-12-223/5, LRT-12-223/3 and LRT-12-223/4 tools from the left cylinder head camshafts.

26. Loosen LRT-12-222, unscrew 2 bolts securing LRT-12-221 to right cylinder head and remove tool LRT-12-221.

27. Establish the top forward cover of a drive of the mechanism timing on the right head of cylinders.

V8 engine, REPAIR WORKS, Upper front timing cover of the right cylinder head.

28. Establish the top forward cover of a drive of the mechanism timing on the left head of cylinders.

V8 engine, REPAIR WORKS, Upper front timing cover of the right cylinder head.

29. Remove the LRT-12-227 pin from the retainer hole.

30. Install 4 oil distribution tubes on the left and right cylinder heads, screw in and tighten the 20 mounting bolts.

31. Establish a back lifting eye of the right head of cylinders, screw and tighten 2 bolts of its fastening.

32. Screw in and tighten 8 spark plugs. Tightening torque 31 Nm.

33. Establish a valvate cover of the right head of cylinders.

V8 engine, REPAIR WORK, Right cylinder head valve cover gasket.

34. Install the valve cover of the left cylinder head.

V8 engine, REPAIR WORK, Left cylinder head valve cover gasket.

35. Install the fan guard.

COOLING SYSTEM: V8 engine, REPAIR WORK, Viscous fan clutch.

36. Fill the cooling system with coolant.

COOLING SYSTEM: V8 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

37. Attach "negative" battery terminal.

Comments on this article