Removing

1. Remove the cylinder head gasket.

TD6 ENGINE, ENGINE OVERHAUL, Cylinder Head Gasket.

2. Remove connecting rod bearings.

TD6 ENGINE, ENGINE OVERHAUL, Replacement of connecting rod bearings.

Disassembly

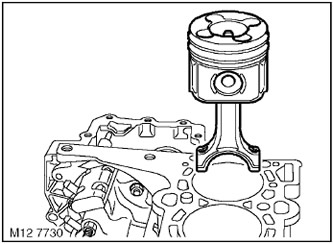

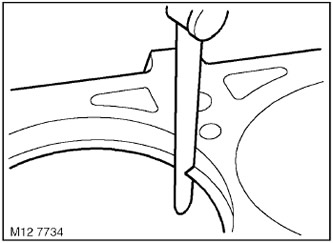

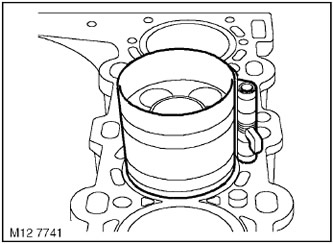

1. Remove carbon from the top of the cylinder.

2. Carefully knock the piston out of the cylinder.

CAUTION: When knocking out the piston, make sure that the connecting rod does not touch the cylinder surface and oil nozzles (if they are installed)

3. Knock out the remaining 5 pistons.

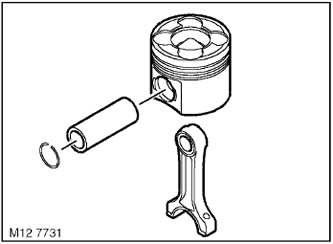

4. Clamp the connecting rod in a vise with soft jaws.

5. Carefully remove and discard the 2 piston pin circlips.

6. Push the piston pin out of the piston and connecting rod and remove the piston.

Examination

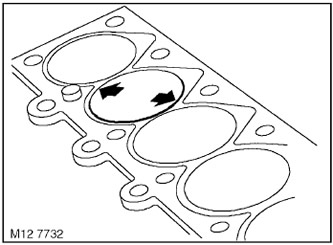

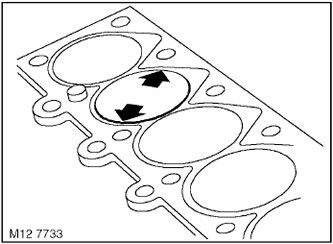

1. Pistons and cylinders: Measure the diameter of the cylinder in the lower, middle and upper chords in the plane shown in the figure.

2. Write down the measurement results. Repeat the measurement in the plane shown in the figure and for two groups of measurements, calculate the ovality and taper of the cylinder.

TECHNICAL DATA, Engine - Td6.

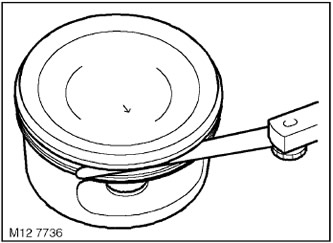

3. Starting with #1 piston, measure the skirt diameter in a plane perpendicular to the piston pin axis, 12 mm from the bottom edge of the skirt:

4. Compare the piston diameter with the cylinder diameter and calculate the clearance between the piston and the cylinder.

TECHNICAL DATA, Engine - Td6.

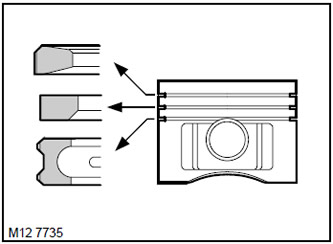

5. Remove the compression rings, compound oil scraper rings and the oil scraper ring expander from the new piston.

6. Insert new rings into the cylinder and check the mounting gap in them at a distance of 30 mm from the upper plane of the block. When measuring the clearance, make sure that the rings are in a plane perpendicular to the axis of the cylinder.

TECHNICAL DATA, Engine - Td6.

7. Put on the oil scraper rings and the ring expander, make sure that the rings in the lock stand in a joint and do not overlap.

8. Put on the second compression ring with the 'TOP' mark facing up.

9. Fit the top compression ring with the 'TOP' mark facing up.

10. Check up a backlash between a ring and a piston flute.

TECHNICAL DATA, Engine - Td6.

11. Check the fit of the piston pin in the piston: the pin should move with little effort, without jamming or noticeable play.

12. Check the wear of the bushing of the upper head of the connecting rod, check the fit of the pin in the bushing: the pin should move with little effort, without jamming and noticeable play. The bushings of the upper heads of the connecting rods cannot be replaced. If necessary, the connecting rod assembly is changed.

13. Be convinced of absence of deformation of a rod. Install a new bearing with a running-in layer, marked BLUE, into the connecting rod. Install the new bearing marked RED into the connecting rod cap.

14. Establish covers on rods, screw in place former bolts and tighten them the moment of 5 Нм.

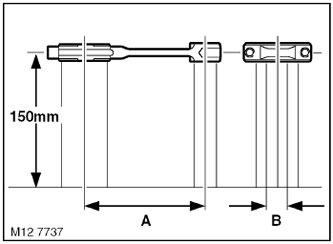

15. Check the geometry of the connecting rods (no deformation), defining the size of A and B, as shown in the figure.

TECHNICAL DATA, Engine - Td6.

16. Check for deformation on both sides of the connecting rod.

17. After checking the parallelism of the heads, remove the connecting rod cap bolts and arrange them in the installation order.

Assembly

1. Wipe the cylinder bore, pistons, piston rings and connecting rods.

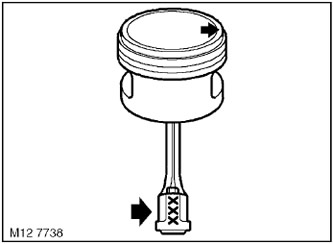

2. Place the pistons on your connecting rods, with the number on the bottom of the connecting rod head facing the arrow on the piston crown as shown.

3. Lubricate the piston pins, piston bores and connecting rod tops with engine oil. Insert the piston pins and secure them with new retaining rings, which must be fully engaged in their grooves.

4. Lubricate the pistons, piston rings and cylinder bore with clean engine oil.

5. Check the freedom of movement of the rings in their grooves. Separate the locks of the rings by 120°relative to each other so that the locks are not on the most loaded side of the piston (the left side of the piston when looking at its front).

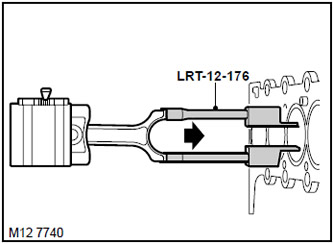

6. Compress the piston rings with a special tool.

7. Slide guides LRT-12-176 onto the connecting rod to protect the cylinder bore and crankpin.

8. Insert the piston into the cylinder so that the arrow on the bottom of the piston points towards the front of the engine.

9. Remove guides LRT-12-176 from connecting rods.

Repair

1. Install connecting rod bearings.

ENGINE TD6, ENGINE OVERHAUL, Replacement of connecting rod bearings.

2. Check piston protrusion.

TD6 ENGINE, ENGINE OVERHAUL, Checking piston protrusion with cylinder head removed.

3. Install the cylinder head gasket.

TD6 ENGINE, ENGINE OVERHAUL, Cylinder Head Gasket.

Comments on this article