GENERAL INFORMATION, Precautions when working with electrical equipment.

Removing

1. Disconnect "negative" battery wire.

2. Drain the engine oil and remove the filter element from the oil filter housing.

MAINTENANCE, SERVICE OPERATIONS, Engine oil and oil filter - Td6 engine.

3. Remove differential.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, REPAIR WORK, Final drive with differential assembly - Td6.

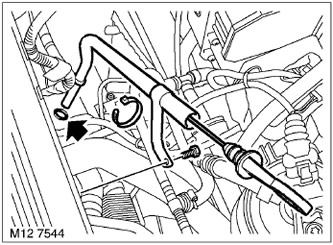

4. Remove the wire harness from the dipstick tube.

5. Remove the clamp securing the fuel hose to the oil dipstick tube.

6. Remove the dipstick.

7. Turn away a bolt of fastening of a tube of an oil probe.

8. Remove the dipstick tube and discard the O-ring.

9. Remove the air conditioning compressor drive belt tensioner.

AIR CONDITIONING, REPAIR WORKS, Compressor drive belt tensioner - Td6 engine.

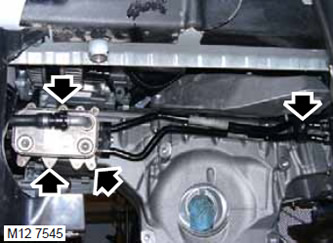

10. Loosen the nut securing the transmission oil cooling system hoses to the engine sump.

11. Turn away 3 bolts of fastening of the heat exchanger of cooling of transmission oil, take the heat exchanger aside and fix it.

12. Turn away 4 bolts of fastening of a transmission to the pallet of the engine.

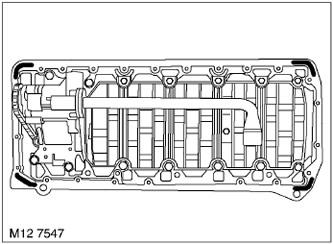

13. Turn away 25 bolts of fastening of the pallet and remove the pallet.

14. Remove and discard pan gasket.

Installation

1. Wipe down the drip tray and mating surface.

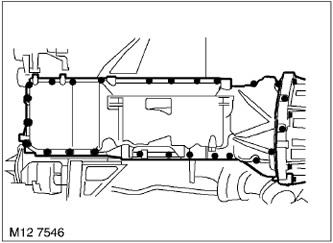

2. Apply a 2 mm thick bead of STC 50550 sealant to the areas shown in the figure.

3. Install a new gasket on the pallet, put the pallet in its place, screw in the fastening bolts but do not tighten them.

4. Screw in bolts of fastening of the pallet to a transmission, slightly tighten them and weaken again. With this technique, the rear flange of the pallet will take the correct position in relation to the gearbox.

5. Tighten the sump-to-engine bolts evenly and sequentially. The M8 bolts are tightened to a torque of 22 Nm, the M6 bolts are tightened to a torque of 10 Nm.

6. Tighten bolts of fastening of the pallet to a transmission. Tightening torque 22 Nm.

7. Reinstall the engine oil cooler and tighten its mounting bolts.

8. Tightening torque 10 Nm. Tighten the transmission oil cooler hose nut.

9. Tightening torque 10 Nm. Install the A/C compressor drive belt tensioner.

AIR CONDITIONING, REPAIR WORKS, Compressor drive belt tensioner - Td6 engine.

10. Wipe the dipstick tube and its seat in the sump.

11. Put an O-ring on the dipstick tube, insert the tube into the socket and tighten the bolt of its fastening. Tightening torque 6 N «m.

12. Install the fuel hose clamp to the oil dipstick tube.

13. Attach the wire harness to the dipstick tube.

14. Install differential.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, REPAIR WORK, Final drive with differential assembly - Td6.

15. Insert a new filter element of the lubrication system and fill the engine with oil.

MAINTENANCE, SERVICE OPERATIONS, Engine oil and oil filter - Td6 engine.

16. Attach "negative" wire to the battery.

Comments on this article