GENERAL INFORMATION, Precautions when working with electrical equipment.

Removing

1. Disconnect "negative" battery wire.

2. Remove the valve cover with gasket.

ENGINE TD6, REPAIR WORK, Valve cover gasket.

3. Remove the heat exchanger of the exhaust gas recirculation system (EGR).

EMISSION REDUCTION SYSTEMS - Td6, REPAIRS, EGR cooler (EGR).

4. Remove the accessory drive belt.

ENGINE START AND BATTERY CHARGING SYSTEM, REPAIR WORK, Attachment drive belt - Td6 engine.

5. Remove the vacuum pump.

BRAKE SYSTEM, REPAIR WORK, Vacuum pump -Td6.

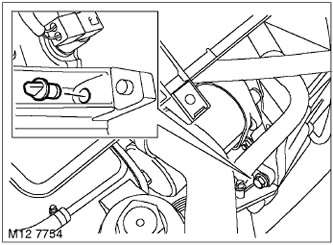

6. Remove the chain tensioner plug from the front cover.

7. Turn out a cap of an opening of a clamp T.M.T. crankshaft.

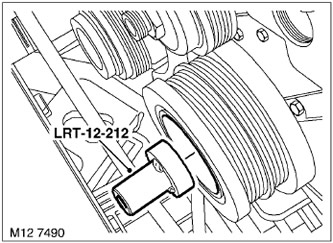

8. Using tool LRT-12-212 mounted on the crankshaft pulley, rotate the crankshaft in the direction of normal rotation until the piston of the first cylinder is in the T.M.T. compression stroke.

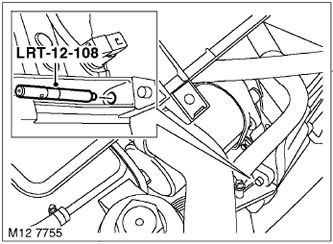

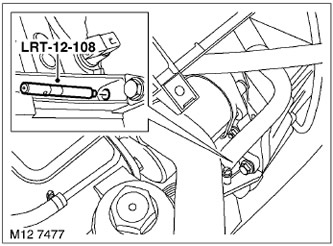

9. To fix the crankshaft in the T.M.T. cylinder 1, install tool LRT-12-108.

CAUTION: Do not rotate the engine against the normal direction of rotation.

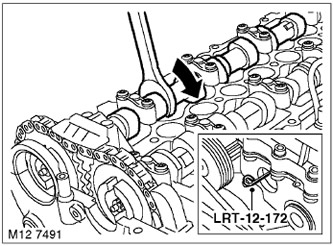

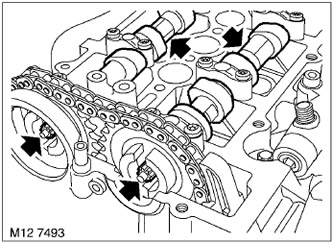

10. Rotate the exhaust camshaft with the hex wrench to fully compress the chain tensioner.

11. Lock the cocked tensioner with LRT-12-172.

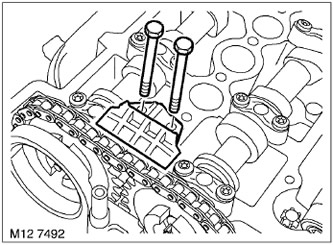

12. Turn out two bolts and remove an oil-supply directing level. Dispose of the gasket.

13. Holding the camshafts by the hexagons, unscrew the bolts securing both sprockets.

14. To avoid damaging the valves when rotating the camshafts, remove tool LRT-12-108 and turn the crankshaft approximately 45°in the opposite direction to normal rotation.

15. Turn out and utilize bolts of fastening of asterisks, remove asterisks from cam-shafts.

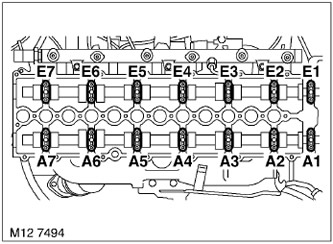

16. Pay attention to how the camshaft bearing caps are marked. The intake camshaft is marked with a letter "E" and the lids are marked from "E1" before "E7", starting from the sprocket, when looking at the engine from the exhaust side. Exhaust camshaft marked with letter "A", and covers are marked from "A1" before "A7", starting from the sprocket, when looking at the engine from the exhaust side.

17. Consistently and evenly loosen and turn away 14 bolts of fastening of covers of bearings of a cam-shaft.

18. Remove the camshaft bearing caps.

19. Remove the camshaft.

Installation

1. Wipe the camshaft, bed journals and bearing caps.

2. Lubricate the camshaft, its beds and covers.

3. Place the camshaft in the cylinder head in a position approximately corresponding to T.M.T. the start of the stroke of the first cylinder.

4. Install the bearing caps in their places, screw in the mounting bolts and tighten them, evenly and consistently, with a torque of 10 Nm.

5. Install the sprockets on the camshafts and tighten them with new bolts so that the sprockets can rotate freely without end runout.

6. Wipe the oil guide bar and counter mating surface.

7. Install a new gasket on the oil guide bar.

8. Install the bar in place and tighten it with bolts. Tightening torque 10 Nm.

9. Rotate the crankshaft in the direction of normal rotation to install the LRT-12-108 tool and lock the crankshaft in the T.M.T. compression stroke.

CAUTION: Do not rotate the engine against the normal direction of rotation.

10. While holding the exhaust camshaft by the hex wrench, tighten the sprocket mounting bolt and rotate the exhaust camshaft in the direction of normal rotation to fully compress the chain tensioner.

11. Remove tool LRT-12-172 from the tensioner.

12. Loosen the exhaust camshaft sprocket bolt just enough so that it can rotate freely without end play.

13. Wipe the tensioner window plug and plug seat.

14. Replace the plug and tighten it. Tightening torque 30 Nm.

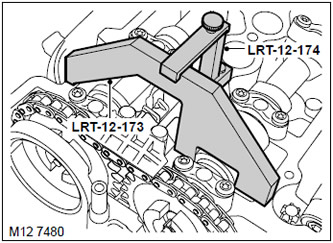

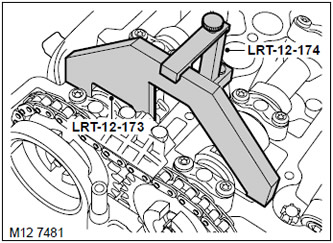

15. Install tool LRT-12-174 on the cylinder head.

16. Using LRT-12-173, set the intake camshaft to the correct position and tighten the LRT-12-174 mounting bolt.

17. Holding the intake camshaft with a hexagon wrench and using a torque sector, tighten the intake camshaft sprocket bolt to 20 Nm and tighten it another 35°.

18. Loosen the LRT-12-174 mounting bolt and remove the LRT-12-173 from the intake camshaft.

19. Using LRT-12-173, position the exhaust camshaft in the correct position and tighten the LRT-12-174 mounting bolt.

20. Holding the exhaust camshaft with a hexagon wrench and using the torque sector, tighten the exhaust camshaft sprocket bolt to 20 Nm and tighten it another 35°.

21. Remove tools LRT-12-174 and LRT-12-173.

22. Remove tool LRT-12-108 to free crankshaft.

23. Using the LRT-12-212 tool installed on the crankshaft pulley, turn the crankshaft two turns in the direction of normal rotation until the piston of the first cylinder is in the T.M.T. compression stroke.

24. To fix the crankshaft in the T.M.T. cylinder 1, install tool LRT-12-108.

CAUTION: Do not rotate the engine against the normal direction of rotation.

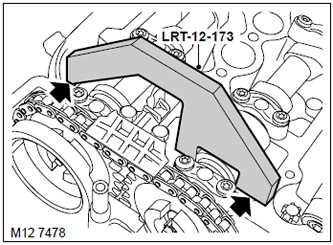

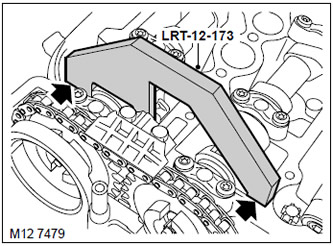

25. Install tool LRT-12-173 on intake camshaft.

26. If the intake camshaft is in the correct position, then the bearing surfaces of the tool LRT-12-173 will touch the plane of the valve cover connector on both sides.

27. Remove tool LRT-12-173 from the intake camshaft and install it on the exhaust camshaft.

28. If the exhaust camshaft is in the correct position, then the bearing surfaces of the tool LRT-12-173 will touch the plane of the valve cover connector on both sides.

29. If necessary, the valve timing adjustment should be repeated.

30. Remove tools LRT-12-174 and LRT-12-108.

31. Wrap the plug of the hole of the T.M.T. crankshaft.

32. Install the vacuum pump.

BRAKES, Brake disc - front brakes, Vacuum pump - Td6.

33. Install the accessory drive belt.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Attachment drive belt - Td6 engine.

34. Install the exhaust gas recirculation heat exchanger.

EMISSION REDUCTION SYSTEMS - Td6, REPAIRS, EGR cooler (EGR).

35. Install the valve cover with gasket.

ENGINE TD6, REPAIR WORK, Valve cover gasket.

36. Attach "negative" wire to the battery.

Comments on this article