Removing

1. Remove hydraulic lifters.

ENGINE TD6, REPAIR WORKS, Hydraulic compensators.

Disassembly

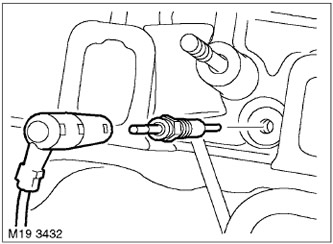

1. Disconnect the connector from the fuel pressure sensor.

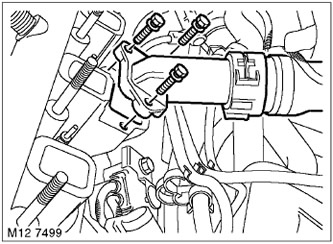

2. Disconnect connectors from glow plugs.

3. Disconnect the connector from the coolant temperature sensor.

4. Turn away 3 bolts and remove a branch pipe of system of cooling from a head of cylinders. Dispose of the gasket.

5. Turn away nuts and disconnect fuel tubes from a fuel stage and from the fuel pump. Remove the fuel pipe support bushing.

CAUTION: To prevent contamination, install plugs on exposed connectors.

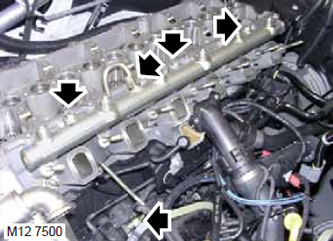

6. Turn away 3 bolts and remove a fuel rail.

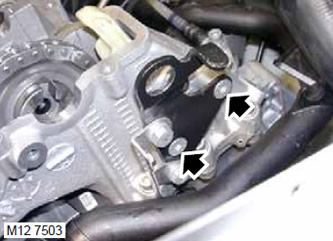

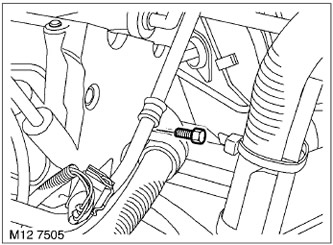

7. Turn away 2 bolts of fastening of a heat-shielding screen and tubes of system EGR to a final collector.

8. Remove the heat shield.

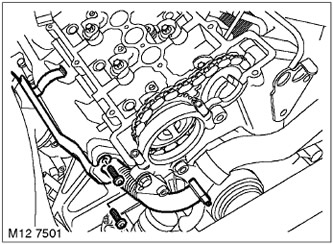

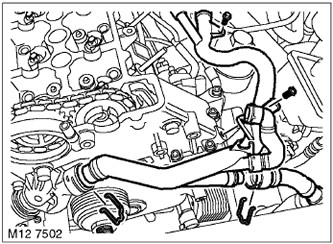

9. Remove the tube of the EGR system with a clamp.

10. Turn away two bolts of fastening of a lifting eye and remove an eye.

11. Turn away a collar and disconnect a hose of a broad tank from a tube of system of cooling.

12. Turn away 2 bolts of fastening of system of cooling of a tube.

13. Turn away a collar, disconnect a tube of system of cooling from the case of the thermostat and take it aside.

14. Turn away 3 bolts of fastening of a turbocharger to a final collector. Dispose of the gasket.

15. Turn away a bolt of fastening of a supporting collar of a vacuum hose and a plait of wires to a head of cylinders.

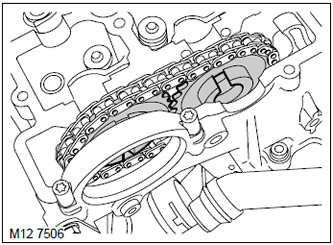

16. Remove the camshaft drive chain from the sprockets.

17. Remove and dispose of the clamps of the damper of the gas distribution chain.

18. Remove chain guides. Access to the damper from the intake manifold is improved when the cylinder head is removed.

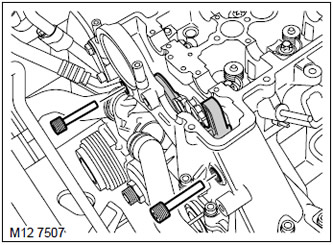

19. Turn away 7 bolts of fastening of a head of cylinders to a cover of the gas distribution mechanism.

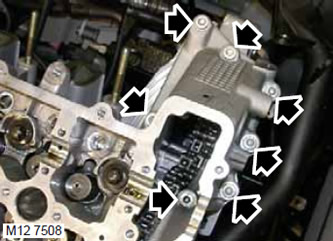

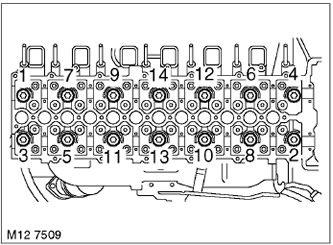

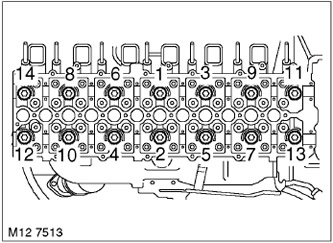

20. In the specified sequence, unscrew and dispose of the 14 cylinder head bolts.

21. Establish lifting eyes on a head of cylinders and fix them on it.

22. Put on lifting chains, release the cylinder head from the pins and remove it. Protruding glow plugs must be protected from damage.

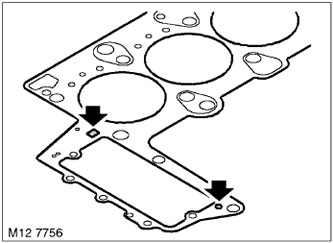

23. By the number of notches in the gasket, determine its thickness. Remove and discard gasket.

Examination

1. Wipe the lower plane of the block head, the upper surface of the cylinder block, the pins and the holes for them. If necessary, remove residual sealant with a hardwood scraper. Do not allow sealant residues to enter the oil supply channels, the cooling system and the threaded sockets.

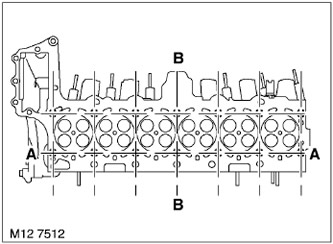

2. Using a straightedge and a feeler gauge, check the deformation of the bottom plane of the head in the directions shown in the figure.

TECHNICAL DATA, Engine - Td6.

3. If deformation values exceed admissible replace a head of cylinders. Milling of the lower plane of the block head is not allowed.

4. If the connecting rod and piston group has not been replaced, then a new gasket of the same thickness should be used (with the same number of holes), which is the same as the previous one. If a connecting rod-piston group was replaced, then for the correct choice of gasket thickness, it is necessary to measure the protrusion of the pistons.

5. After making sure that the sealant strips on the gasket are not damaged, install the gasket on the cylinder block.

Assembly

1. Lightly coat the new cylinder head bolts with engine oil.

2. Carefully place the cylinder head on the block so that the pins fit into the sockets.

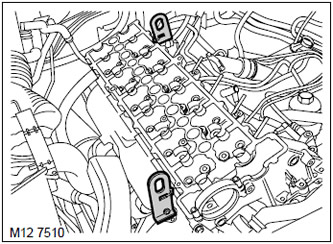

3. Screw in bolts of fastening of a head of the block and tighten them in the specified sequence. Tightening torque 80 Nm. Loosen all bolts half a turn and retighten them. Tightening torque 50 Nm. Using an angle torque wrench, tighten all bolts in the sequence shown by 90°and again by 90°.

4. Tighten bolts of fastening of a head of cylinders to a cover of the gas distribution mechanism. Tightening torque 20 Nm.

5. Wipe the dampers of the timing chain.

6. Replace the chain guides so that the intake manifold side guide is on the lower clip and tighten both new upper clips. Tightening torque 20 Nm.

7. Wipe the camshaft sprockets.

8. Put the camshaft drive chain on the sprockets.

9. Wipe the turbocharger and mating surface on the exhaust manifold.

10. Install the turbocharger on a new gasket and tighten the bolts of its fastening. Tightening torque 50 Nm.

11. Install the vacuum hose and wire harness support clamps, tighten the bolt. Tightening torque 10 Nm.

12. Wipe down the cooling system pipes and mating surfaces.

13. Attach the tube of the cooling system to the thermostat housing and secure it with a clamp.

14. Screw bolts of fastening of a tube of system of cooling and tighten them. Tightening torque 10 Nm.

15. Attach a hose to a broad tank and fix it with a collar.

16. Replace the lifting eye and tighten the bolts. Tightening torque 25 Nm.

17. Wipe the tube of the exhaust gas recirculation system and mating surface.

18. Install the EGR system pipe, heat shield, screw in the mounting bolts, but do not tighten them yet. After installing the EGR cooling heat exchanger, tighten the bolts. Tightening torque 25 Nm.

19. Wipe the coolant hose and mating seat.

20. Put a branch pipe of the cooling system on a new gasket and tighten the bolts. Tightening torque 8 Nm.

21. Install the fuel rail in place and tighten the mounting bolts. Tightening torque 24 Nm.

22. Install the high pressure fuel pipes and support sleeve, tighten the nuts on the pipes. Tightening torque 20 Nm.

23. Connect the connector to the coolant temperature sensor.

24. Put the connectors on the glow plugs.

25. Connect the connector to the fuel pressure sensor.

Installation

1. Install hydraulic lifters.

ENGINE TD6, REPAIR WORKS, Hydraulic compensators.

Comments on this article