General remarks

Always change oil seals (cuffs) to new ones in case of dismantling the seal (when only the seal was dismantled and when the seal was dismantled as part of an assembly unit). NEVER install seals that have been stored incorrectly or have been tampered with, such as hanging from a hook or nail.

- Before installation, carefully inspect the seal to ensure that it is intact and free from foreign particles.

- The surface on which the working edge of the cuff will work must be smooth, without scratches and burrs. Cuff mating part (shaft) must be replaced if its sealing surface does not meet this requirement.

- During installation, protect the collar against damage from sharp edges. Insulate the surface that can damage the collar during installation with a technological sleeve or wrap it with tape.

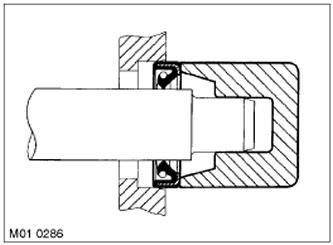

- To avoid destruction of the working edge of the cuff during start-up, lubricate it with the recommended grade of lubricant. If the cuff has two working edges, then also fill the space between them with grease.

- If the cuff has a spring, then make sure that the latter is installed correctly. Install the cuff so that its working edge is directed towards the sealed liquid. Then gently slide it on the shaft towards the working neck. Use technological sleeves to protect the working edge of the cuff from damage by sharp edges, threads or slots. If there is no technological sleeve, then use an insulating tape to protect the cuff edge from damage.

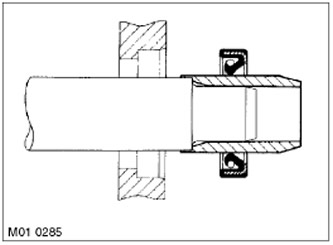

- Lubricate the outer diameter of the seal with grease, direct the end of the seal into the body bore and press the seal into place. For pressing, use a suitable mandrel to prevent the cuff from tilting. In some cases, it is advisable to first press the cuff into the housing, and then install the shaft. Do not allow the weight of the shaft to be carried by the collar.

- For installation of cuffs use the recommended tool and adaptations. If you do not have the recommended fixture, then you can use a piece of suitable pipe, its outer diameter should be approximately 0.4 mm smaller than the outer diameter of the cuff. If a hammer is used to press the cuff, then work with it VERY CAREFULLY.

- Press the cuff to the full depth until it stops against the ledge of the body, if the boring for the cuff is made without a ledge, then press the cuff flush with the body. When pressing the cuff, make sure that it is not skewed.

Comments on this article