Dismantling

1. Raise the front of the car.

WARNING: Do not work under a vehicle raised only on a jack or lift. Always install safety props.

2. Remove the front left wheel.

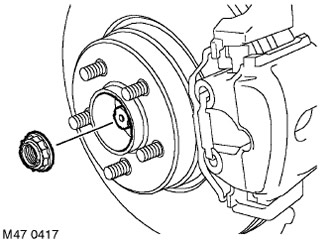

3. Loosen the wheel hub nut retainer.

4. With the help of an assistant depressing the brake pedal, remove and discard the wheel hub nut.

5. Remove the brake disc.

BRAKING SYSTEM, REPAIR WORKS, Brake disc - front brake mechanisms.

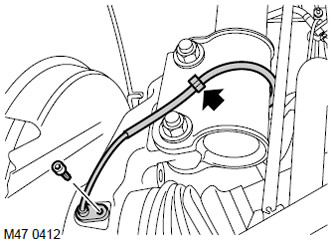

6. Release the wheel speed sensor cable from the retainer.

7. Release the cable from the retainer on the shock absorber, remove the Allen screw and remove the wheel speed sensor from the wheel bearing support.

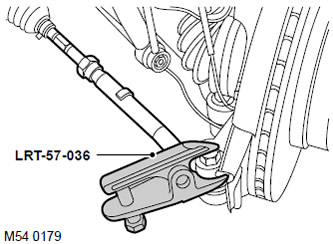

8. Remove and discard the left ball stud to steering knuckle nut.

9. Screw an M14 nut onto the end of the ball stud, flush with the threaded end of the stud.

10. Using tool LRT-57-036, separate the ball pin from the steering knuckle. Remove the M14 nut and remove the ball pin from the steering knuckle.

CAUTION: Check that the ball stud boot is not damaged. A damaged protective boot will cause failure of the ball joint.

11. Turn away a nut of fastening of draft of the sensor of vertical position of a body to the bottom lever and release draft.

WARNING: Hold the ball joint from turning with an open end wrench on the flat grooves.

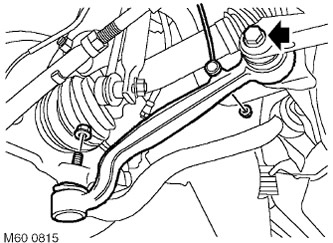

12. Loosen a quarter of a turn the bolt securing the lower arm to the subframe.

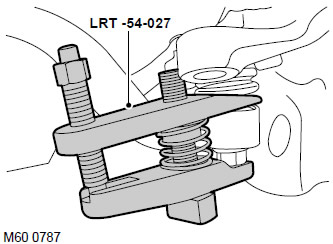

13. Remove the nut securing the lower arm ball joint to the wheel bearing support.

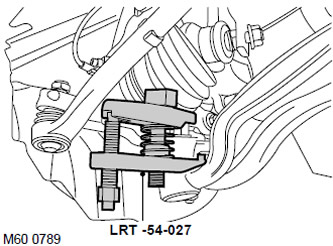

14. Using tool LRT-54-027, release the lower arm ball joint and separate the lower arm from the wheel bearing support.

CAUTION: Check that the ball stud boot is not damaged. A damaged protective boot will cause failure of the ball joint.

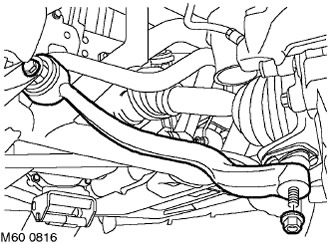

15. Loosen a quarter-turn bolt securing the linkage to the subframe.

16. Turn away a nut of fastening of draft to the spherical hinge.

17. Using tool LRT-54-027, separate the rod from the ball joint.

CAUTION: Check that the ball stud boot is not damaged. A damaged protective boot will cause failure of the ball joint.

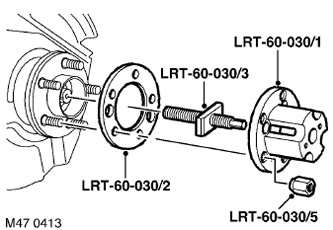

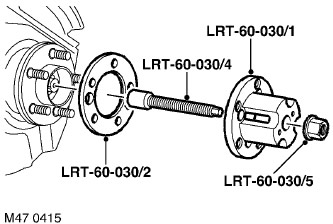

18. Install the LRT-60-030/3 central screw into the LRT-60-030/1 fixture and connect it to the hub through the LRT-60-030/2 intermediate flange. Secure the connection with the nut LRT-60-030/5.

19. While tightening the central screw, press the drive shaft out of the wheel hub.

20. Remove fixtures.

21. Install a container to collect the escaping oil.

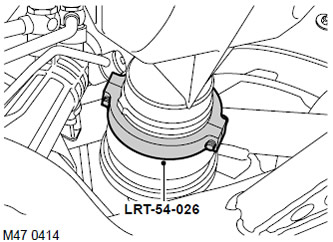

22. Install tool LRT-54-026 on the drive shaft inner joint.

23. Separate the drive shaft from the differential using levers.

24. Release the drive shaft from the hub.

25. Remove the drive shaft assembly and keep it in a horizontal position so as not to damage the differential seal.

26. Remove and discard the driveshaft circlip.

Assembly

1. Wipe the end of the drive shaft and the differential bushing.

2. Install a new retaining ring on the end of the drive shaft.

3. Lubricate the seal lips with clean gear oil.

FILLING CAPACITIES, USED OPERATING LIQUIDS, OILS AND SEALANTS, Lubrication system.

4. Install the end of the drive shaft into the differential ensuring that the circlip is fully engaged.

CAUTION: Push down on the drive shaft to make sure the retaining ring is seated in its groove and holds the shaft.

5. Clean the drive shaft and hub splines from dirt.

6. Apply some lubricant to splines and o-ring contact surfaces.

FILLING CAPACITIES, USED OPERATING LIQUIDS, OILS AND SEALANTS, Lubrication system.

7. Place the end of the drive shaft into the hub.

8. Install tool LRT-60-030/4 on the drive shaft.

9. Fit tool LRT-60-030/1 with intermediate flange LRT-60-030/2 and secure with nut LRT-60-030/5.

10. Screw the nut onto the tool LRT-60-030/4 and, tightening the nut, press the drive shaft into the hub.

11. Remove fixtures.

12. Clean the conical surfaces of the ball pins and the nest for their installation from dirt.

13. Connect the rod to the ball joint, install a new fastening nut and tighten it with a torque of 80 Nm.

14. Attach the ball joint of the lower arm to the wheel bearing support, screw on the fastening nut and tighten it with a torque of 80 Nm.

15. Attach draft of the gauge of vertical position of a body to the bottom lever and tighten a fastening nut with the moment of 8 Нм.

CAUTION: Make sure the sensor arm is facing out.

16. Connect the ball joint pin to the steering knuckle, install a new nut and tighten it to 80 Nm.

17. Clean the surface of the wheel speed sensor, apply an anti-stick lubricant, and install it on the wheel bearing support.

FILLING CAPACITIES, USED OPERATING LIQUIDS, OILS AND SEALANTS, Lubrication system.

18. Install the wheel speed sensor Allen screw and tighten the screw to 8 Nm.

19. Attach the sensor cable to the shock absorber.

20. Install the brake disc.

BRAKING SYSTEM, REPAIR WORKS, Brake disc - front brake mechanisms.

21. Replace the new hub nut and tighten the nut to 420 Nm.

22. Lock the nut on the end of the drive shaft.

23. Reinstall the wheel and tighten the nuts to 140 Nm.

24. Remove props and lower the car.

25. Install a new screw securing the lower arm to the subframe, tighten it with a torque of 165 Nm, then tighten it another 90°.

26. Tighten the new screw securing the rod to the subframe with a torque of 165 Nm, then tighten it another 90°.

27.

CAUTION: Nuts and screws must be tightened when the vehicle is properly supported by its wheels on the ground.

28. Add oil to the front axle final drive housing.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, ADJUSTMENTS, Front final drive and differential housing - oil drain and fill.

29. Check up a convergence of forward wheels.

STEERING, ADJUSTMENTS, Front wheel alignment - check and adjustment.

Comments on this article