Dismantling

1. Remove the exhaust system.

EXHAUST MANIFOLD AND EXHAUST GAS SYSTEM: Td6 engine, REPAIR WORK, Exhaust system and system components suspension.

2. Raise the rear of the vehicle and jack it up.

WARNING: Do not work under a vehicle raised only on a jack or lift. Always install safety props.

3. Remove the wheel.

4. Release the air from the rear air suspension circuit.

REAR SUSPENSION, ADJUSTMENTS, Pneumatic suspension - air release and filling the system with air.

5. Disconnect the wheel speed sensor wiring from the upper control arm.

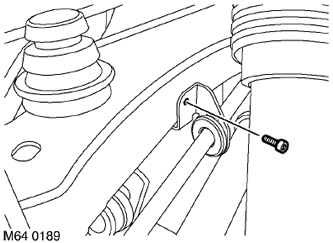

6. Turn away 2 screws like Allen fastenings of a brake hose.

7. Remove the Allen screw securing the parking brake cable bracket.

8. Place a jack as a support under the lower control arm.

9. Mark the location of the eccentric relative to the upper arm.

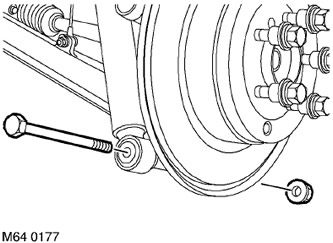

10. Remove and discard the nut and bolt that secures the hub to the upper control arm. Disconnect the hub from the lever.

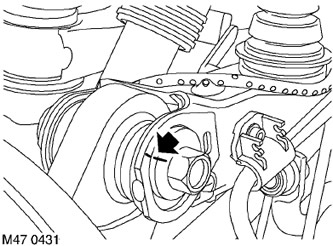

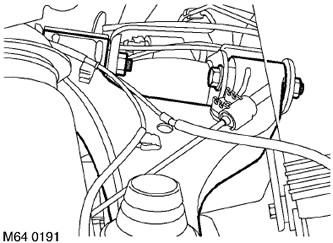

11. Remove the clamp from the top support of the air element.

12. Turn away a bolt of fastening of the shock-absorber to the bottom lever.

13. Disconnect the shock absorber from the lower arm.

14. Support the subframe assembly on a jack.

15. Turn away 2 bolts of fastening of a stretcher to a body.

16. Lower the subframe approximately 75mm to provide access to the bolts securing the upper arm to the subframe.

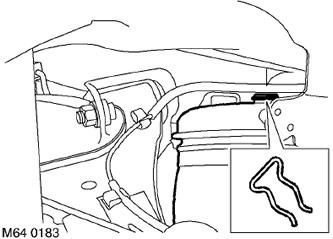

17. Remove washers located on top of all rubber subframe bushings.

18. Turn away 2 bolts of fastening of the top lever.

19. Remove the upper arm.

Assembly

1. Clean the top arm bushings from dirt.

2. Install the upper arm and tighten the bolts without fully tightening them yet.

CAUTION: Nuts and bolts must be tightened with the vehicle body in the normal position.

3. Align the shock absorber with the lower arm, install the mounting bolt and tighten it with a torque of 110 Nm (81 lb ft).

4. Tighten the bolts securing the upper arm to the subframe with a torque of 165 Nm (121 lb ft).

5. Install the washers on the subframe bushings.

6. Raise the subframe, install the bolts securing the subframe to the body and tighten them to a torque of 165 Nm (122 lb ft).

7. Pressurize the circuit to secure the upper air cell support. Install the clamp.

8. Align the hub with the upper arm and install a new bolt. Install the eccentric according to the mark made earlier and lightly tighten the bolt.

9. Move the parking brake cable bracket to the upper suspension arm and tighten the Allen screw with a torque of 5 Nm (3.7 lb ft).

10. Screw the Allen type screws securing the brake hose to the upper suspension arm and tighten them to a torque of 5 Nm (3.7 lb ft).

11. Fix electroconducting of the gauge of speed of rotation of a wheel.

12. Bring the pressure in the air suspension system to the nominal value.

REAR SUSPENSION, ADJUSTMENTS, Air Suspension Bleeding and filling the system with air.

13. Reinstall the wheel and tighten the nuts to 140 Nm (103 lb ft).

14. Lower the car.

15. Reinstall the exhaust system.

EXHAUST MANIFOLD AND EXHAUST GAS SYSTEM: Td6 engine, REPAIR WORK, Exhaust system and system components suspension.

16. Check wheel alignment.

17. Tighten the bolt securing the upper suspension arm to the hub with a torque of 165 Nm (121 lb ft).

Comments on this article