It is not necessary to release air from the entire air suspension system, it is enough to release it only from the circuit of the air element being replaced.

When disconnecting the Voss fitting from any air suspension element, it must not be removed from the detachable air hose. Do not remove the fitting from the air hose. When removing the fitting from the hose, there is a high chance of scratching it, which can later lead to air leakage from the system.

Dismantling

1. Raise the front of the vehicle and jack it up.

WARNING: Do not work under a vehicle raised only on a jack or lift. Always install safety props.

2. Remove the wheel (wheels).

3. Bleed air from the air element being replaced.

FRONT SUSPENSION, ADJUSTMENTS, Air suspension system - air release and filling the system with air.

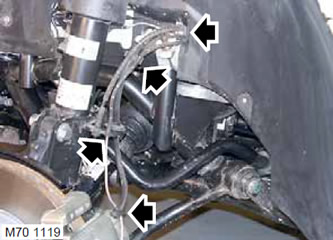

4. Disconnect the wheel speed sensor wiring and air hose from the shock absorber.

5. For left air element only: Disconnect the brake pad wear sensor electrical wire from the shock absorber.

6. Turn away a nut of fastening of a rack of the stabilizer of cross stability to the shock-absorber.

CAUTION: Use a socket wrench to prevent rotation of the ball joint.

7. Remove the stabilizer link and washer.

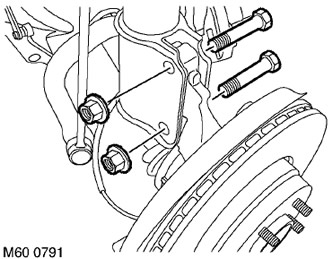

CAUTION: Mark the location of the washer for later installation.

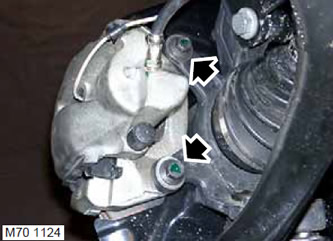

8. Turn away two bolts of fastening of a brake support to a nave. Remove the caliper from the hub and attach to the side.

CAUTION: Do not let the caliper hang on the brake hose.

9. Remove the nut at the end of the tie rod.

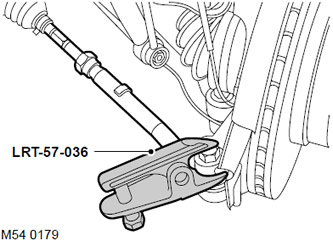

10. Screw an M14 nut onto the end of the ball stud, flush with the threaded end of the stud.

11. Using tool LRT-57-036, disconnect the ball pin from the steering knuckle. Remove the M14 nut and remove the ball pin from the steering knuckle.

CAUTION: Check that the ball joint boot is not damaged. A damaged boot will result in hinge failure.

12. Place a jack as a support under the lower control arm.

13. Turn away 2 nuts from bolts of fastening of a nave to the shock-absorber.

14. Disconnect the hub from the shock absorber and lower arm and clean the shock absorber.

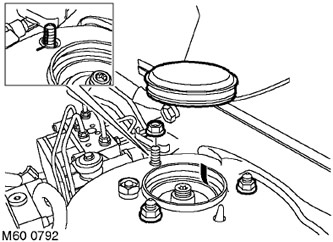

15. Remove the cover from the top support.

16. Unscrew the fastening nut of the pneumatic element and shock absorber assembly, which is located on the inside, and mark the relative position of the rack and the upper support for subsequent assembly.

17. Remove the 2 remaining nuts and disconnect the air element and shock absorber assembly by lowering it just enough to allow access to the air hose fitting.

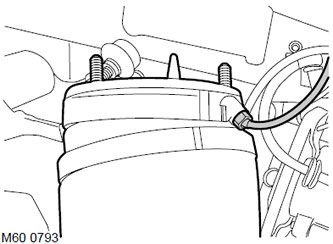

18. Disconnect the fitting from the pneumatic elastic element.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

19. Remove the air element and shock absorber assembly.

20. Remove the paper shim from the air cell and shock absorber assembly and discard.

Assembly

1. Clean the location of the air element and shock absorber.

CAUTION: Inspect the air element for damage. If the pneumatic element is damaged, it must be replaced.

2. When installing a new air element and shock absorber assembly, remove the air fitting from it.

3. Install a new paper gasket on the air element and shock absorber assembly.

4. Install the air element and shock absorber assembly, connect the air hose, but do not tighten the connection yet.

CAUTION: Clean the air hose connection.

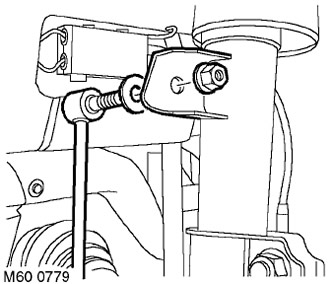

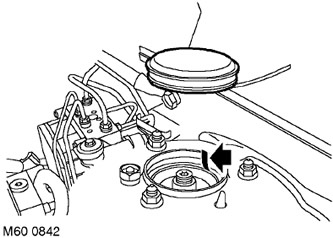

5. Attach the air element and shock absorber assembly to the body. Screw on the top mounting nuts, align the locating pin with the mark and finally tighten the nuts to a torque of 56 Nm (42 lb ft).

CAUTION: Make sure that the mark on the gasket is visible through the large hole made in the support (see picture).

6. Place the cover on the top support.

7. Tighten the air hose fitting to 3.5 Nm (2.6 lb ft).

8. Connect the hub to the shock absorber, install the bolts and tighten them with a torque of 250 Nm (184 lb ft).

9. Clean the tapered surfaces of the ball pin and steering knuckle socket from dirt.

10. Connect the ball pin to the steering knuckle, install a new nut and tighten it with a torque of 80 Nm (59 lb ft).

11. Clean the mating surfaces of the brake caliper and hub.

12. Install the caliper on the hub and tighten the bolts with a torque of 110 Nm (81 lb ft).

13. Attach the brake hose and wheel speed sensor wiring to the shock absorber.

14. Left air element only: Install the brake pad wear sensor.

15. Install the washer, connect the anti-roll bar, screw on the nut and tighten it with a torque of 100 Nm (74 lb ft).

ATTENTION: The hardened washer must be installed in the same position that it occupied before dismantling.

16. Bring the pressure in the air suspension system to the nominal value.

FRONT SUSPENSION, ADJUSTMENTS, Air suspension system - air release and filling the system with air.

ATTENTION: Before removing the prop and placing the vehicle on the wheels, it is necessary to bring the pressure in the air suspension system to the nominal value.

17. Replace the wheel (wheels) and tighten the nuts with a torque of 140 Nm (103 lb ft).

18. Remove the prop (props) and lower the car.

19. Check up corners of installation of forward wheels.

Comments on this article