Dismantling

1. Put the car on a lift.

2. Disconnect the negative plug from the storage battery.

3. Remove the cooling fan.

COOLING SYSTEM: Td6, REPAIR WORK, Viscous fan clutch.

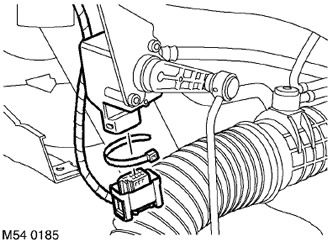

4. Remove the air tube.

HEATING AND VENTILATION, REPAIR WORKS, Air filter - air intake.

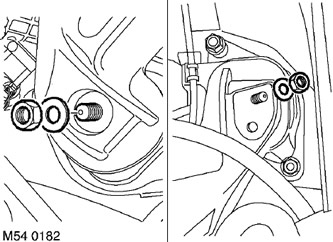

5. Remove the two engine mount nuts.

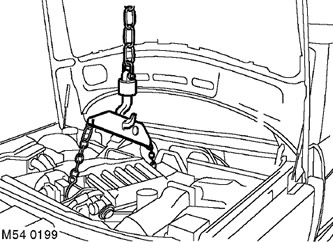

6. Install tool LRT-12-216 on engine mounting tabs.

7. Attach the chain to the motor mounting brackets and tension the chain with the weight of the motor.

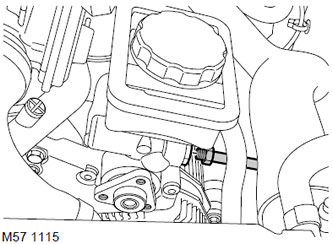

8. Drain the oil from the final drive housing.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, ADJUSTMENTS, Front final drive and differential housing - oil drain and fill.

9. Remove the front propeller shaft.

DRIVE SHAFTS, REPAIR WORKS, Cardan shaft - front.

10. Remove the seal from the inner end of the right drive shaft.

DRIVE SHAFTS, REPAIR WORKS, Seal - drive shaft - front - right.

11. Remove differential seal.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, REPAIR WORK, Seal - differential output shaft.

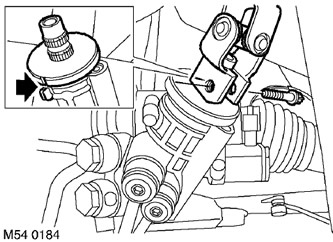

12. Turn out the Torx screw of the lower hinge of a steering shaft.

13. Turn the steering wheel to the straight ahead position, align the marks on the steering gear shaft and remove the key from the ignition.

CAUTION: Do not turn the steering wheel while the intermediate shaft or universal joint is disconnected as this will damage the rotary slip ring and steering wheel controls.

14. Disconnect the steering shaft from the gear shaft.

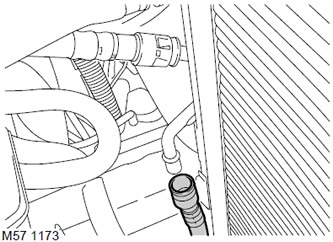

15. Release a vacuum hose from three clamps on the left support of the engine.

16. Disconnect the vacuum supply hose from the tee.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

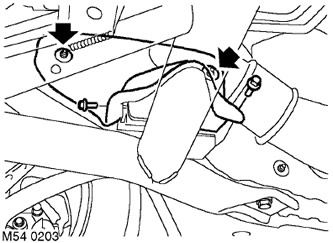

17. Mark position of clips and remove clips of fastening to a subframe of a cable of the sensor of position of a body and the sensor.

18. Remove blocks from electric sockets of gauges of provision of a body.

19. Remove the steering angle sensor connector block.

20. Install a container to collect the flowing fluid.

21. Loosen the union nut, disconnect the high pressure hose from the power steering pump and discard the o-ring.

CAUTION: Before disconnecting or removing system components, make sure that the surfaces adjacent to the connection points are free of dirt. Install plugs in fittings and piping to keep dirt out of the system.

22. Remove a nut of a bracket of fastening of a hose of a steering to an arm.

23. Loosen and disconnect the return hose from the fluid cooler.

CAUTION: Before disconnecting or removing system components, make sure that the surfaces adjacent to the connection points are free of dirt. Install plugs in fittings and piping to keep dirt out of the system.

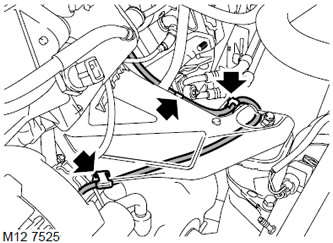

24. Remove the 2 nuts securing each anti-roll bar heat shield to the body and 2 bolts securing each heat shield to the subframe. Remove heat shields.

25. Support the subframe with a jack.

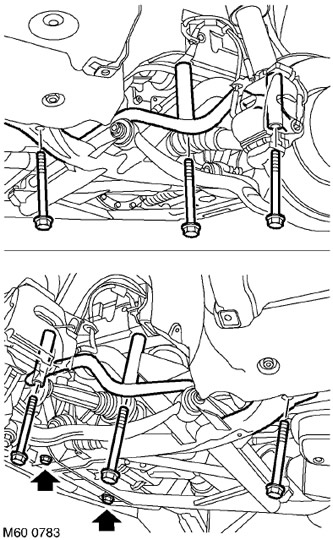

26. Turn out 6 screws of fastening of a stretcher.

27. Turn out 2 screws of fastening of a stretcher to a cross frame.

28. Together with an assistant, lower and remove the subframe assembly.

29. Disconnect the ventilation hose from the final drive housing.

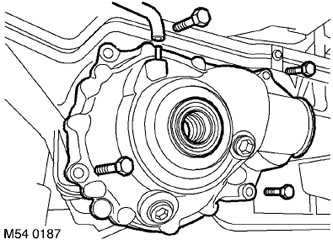

30. Turn out 4 screws of fastening of the main transfer and by means of the assistant remove the main transfer in gathering. Remove and discard the O-ring.

Assembly

1. Clean the final drive housing and all mating surfaces.

2. Install a new O-ring in the final drive housing and lubricate it with petroleum jelly.

3. With the help of an assistant, carefully install the final drive assembly. Tighten the fastening screws with a torque of 102 Nm.

4. Attach a ventilating hose to a case of the main transfer.

5. Clean the mating surfaces of the subframe and car body.

6. Install the subframe assembly with an assistant.

7. Tighten the 6 screws securing the subframe to the body with a torque of 165 Nm. Tighten the 2 rear screws another 90°.

8. Tighten the 2 screws securing the subframe to the transverse frame with a torque of 132.5 Nm.

9. Install the anti-roll bar heat shields and tighten the 2 bolts and nuts.

10. Lower the engine onto stands.

11. Tighten the nuts securing the engine brackets to the supports with a tightening torque of 100 Nm.

12. Wipe places of accessions of hoses of the hydraulic booster.

13. Attach a hose of the hydraulic booster to a cooler of a working liquid.

14. Install a new O-ring on the hose fitting and connect the hose to the pump by tightening the nut to 25 Nm.

15. Attach the hydraulic booster hose to the bracket and tighten the fixing bracket nut to 10 Nm.

16. Connect a block to a socket of the gauge of an angle of rotation of a steering shaft.

17. Attach blocks of electric sockets of forward gauges of vertical position of a body.

18. Route the sensor cables and secure them with the clamps in their original position.

19. Attach vacuum hoses to a tee and fix hoses in clamps.

20. Check the alignment of the marks on the steering shaft and the steering gear shaft and attach the steering shaft. Install the steering shaft pivot screw and tighten to 24 Nm.

21. Install differential seal.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, REPAIR WORK, Seal - differential output shaft.

22. Install the right drive shaft seal.

DRIVE SHAFTS, REPAIR WORKS, Seal - drive shaft - front - right.

23. Reinstall the front propeller shaft.

DRIVE SHAFTS, REPAIR WORKS, Cardan shaft - front.

24. Fill oil into the final drive housing to the required level.

FRONT AXLE MAIN GEAR AND DIFFERENTIAL, ADJUSTMENTS, Front final drive and differential housing - oil drain and fill.

25. Replace the protective shield.

EXTERIOR PARTS, REPAIR WORKS, Engine protection - front.

26. Replace the air tube.

HEATING AND VENTILATION, REPAIR WORKS, Air filter - air intake.

27. Install the cooling fan.

COOLING SYSTEM: Td6, REPAIR WORK, Viscous fan clutch.

28. Connect the negative terminal to the battery.

29. Remove air from the system and add working fluid to the hydraulic booster reservoir.

STEERING, ADJUSTMENTS, Power Steering (PAS) - removal of air.

30. Check and, if necessary, adjust the toe-in of the front wheels.

STEERING, ADJUSTMENTS, Front wheel alignment - check and adjustment.

Comments on this article