1. Treat the outer and inner surfaces of the weld with the recommended protective coating.

2. Repair the damaged underbody seal.

Adhesive materials for the body frame.

3. Use a two-component touch-up system.

4. Treat all unpainted cavities with protective wax.

Restoration of the paintwork

Thoroughly clean the surface with a high-pressure water jet or steam before refinishing.

Rinse the repair area with an aqueous solution of detergent and wipe immediately before applying paint with a cloth soaked in solvent.

Sand the damaged paint surface to a metallic sheen, capturing the unbroken area around the damaged area. Etch the cleaned surface with a phosphate solution to remove all traces of rust and create the first coat for painting. Re-surface the defective surface by etching separately with an acid-based compound and then with a two-component primer, or immediately apply a combination of etch and preparation compound (primer/filler), then apply a two-component top coat. Treat not yet painted areas with a protective wax composition, and then tint.

CAUTION: When preparing the bumper surface for painting, be careful not to damage the shock sensors. If possible, remove only the top layer of the coating. If it is necessary to paint the area of the shock sensors, do not apply a thick layer of paint, as this may impair the operation of the sensors.

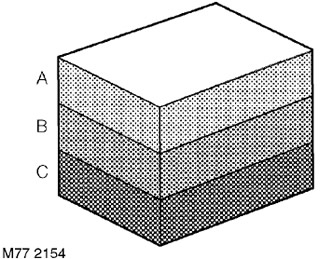

A. Two-component paint coating

b. Two-component preparation and primer

With. Etching with phosphate solution

CAUTION: When drying by heating, the drying temperature should not exceed 65°C. Exceeding this temperature will cause headlight and taillight reflectors to deform and may cause damage to other components.

Comments on this article