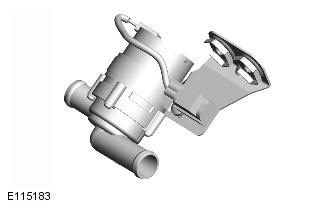

Voltage quality control unit

During the cycle «Stop/Start» VQM module (voltage quality module) keeps the vehicle's electrical systems running by supplying auxiliary voltage to the electronic components during engine restarts. This allows the vehicle's critical systems to continue to operate smoothly during sudden surges in battery current draw.

The car's starter consumes 2kW of electricity and can draw several hundred amps of current from the battery while starting the engine. A sudden increase in current consumption causes an instantaneous voltage drop in all vehicle circuits. Many vehicle electronic systems are designed to operate at nominal 12V, so a sudden drop in battery voltage without a VQM module installed will temporarily disable the following functions:

- audio system

- cellular telephone

- navigation system

- information panel

When the engine is running, the ECM signal activates the VQM relay to bypass the converter and voltage control returns to the normal charging system. The VQM amplifies the voltage for one second, although in many cases it can do so for up to 5 seconds.

VQM is a DC converter (D.C), which converts a fluctuating DC input voltage from 6V to a stable output voltage of 12±0.5V DC.

Rated at 180 watts, it can deliver up to 15 amps at 12 volts. The VQM is capable of handling instant surges of up to 300 watts, enough to keep the car's systems running smoothly during engine start.

VQM faults are reported via a diagnostic channel to the CJB, where they are logged; DTCs can be diagnosed using Land Rover approved diagnostic equipment.

Battery monitoring system

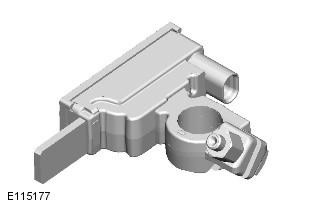

BMS module (battery monitoring systems) installed on the negative battery terminal and is part of the negative battery cable.

The condition of the battery is a fundamental factor in the correct operation of the system "Stop/Start". The battery condition calculation is performed by the BMS module and initiates a cycle "Stop lock" or "Start activator" in cycle "Stop/Start", if the battery does not meet the requirements. For more information, see "Stop interlocks, start activators and start interlocks" below.

Information about the state of the battery is transmitted from the BMS module via the LIN bus (LIN communication protocol) in CJB, where there is a two-way communication channel with the BMS module. Control logic for interlocking engine shutdown and initiating an early restart during a cycle "Start/Stop" located in CJB. The CJB also acts as a gateway that relays this information to the ECM via the high speed CAN bus.

Battery status information is also transmitted from the CJB via the medium speed CAN bus to the instrument cluster. Battery charge warning messages are displayed on the instrument panel to indicate problems with the alternator or the battery monitoring system.

The BMS module continuously calculates the state of the electrical system based on the following data:

- battery aging

- battery charge level

- battery power requirement

If any of these parameters show an insufficient value, the ECM suspends the function "Stop/Start" until the available battery charge increases. These options are listed below:

Battery aging

Although the vehicle is fitted with a high performance AGM battery (glass absorbent partitions), the battery's ability to hold a charge will still decline, albeit at a much slower rate than conventional batteries. This aging is expressed in terms of the amount of charge that the battery can hold until it needs to be replaced.

The battery monitoring system calculates the state of the battery based on the monitoring of a number of parameters:

- air temperature

- charge and discharge procedures

- voltage

- internal resistance

The last battery parameter is stored in a dedicated section of the BMS memory to ensure the most accurate prediction of the battery condition.

State of charge

The BMS analyzes the amount of charge consumed or recharged to determine the current charge of the battery.

Need for nutrition

During the cycle "Stop/Start", when the needs of automotive systems are great, for example, when:

- lights

- climate control system

- audio system

The battery drains faster due to the high current draw.

In this case, the BMS calculates various factors to determine how long the battery will be able to provide power at the current level of consumption. This calculation is used by the CJB to determine if one of the following actions in a cycle is necessary "Stop/Start":

- block engine shutdown

- activate engine restart

To pass this data to the CJB, the BMS module calculates a number of battery variables, including:

- state of charge

- battery surface temperature to calculate the internal temperature

- internal resistance

- voltage

- electrical current flowing in and out of the battery

The battery monitoring system calculates these variables from programmed battery behavior patterns to determine how long the current current can be maintained.

Operating modes of the battery monitoring system

The battery monitoring system has three main modes:

- Active Mode: During normal vehicle operation, battery data is downloaded and processed every second.

- Standby: When the ignition is off, battery data is downloaded every two seconds and calculated every hour to reduce idle current leakage.

- Transport Mode: Battery monitoring intervals are minimal.

Replacing the battery

If a new battery is installed in the vehicle, the BMS (battery monitoring) requires re-calibration, taking into account the increased battery capacity; this is done using Land Rover approved diagnostic equipment. If the diagnostic system is not present, the BMS module will automatically recalibrate, however this may take up to 48 hours depending on vehicle usage. System "Stop/Start" will not function correctly until the BMS module is recalibrated.

If the BMS module is replaced, it will calibrate automatically.

CAUTION: To avoid damage/malfunction of the BMS module, be sure to use a suitable ground point on the body and not the negative battery terminal.

For more information, see the chapter: Battery (414-01 Battery, battery mount and wires, Diagnostics and checks).

Neutral sensor

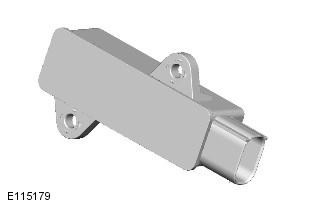

PLCD sensor (non-contact permanent magnet linear displacement sensor) located on the outer surface of the transmission case and is hardwired to the ECM. The sensor is designed to determine the inclusion of a neutral gear within the calibrated window.

When replacing the neutral sensor, no calibration is required, but it is monitored and a DTC will be set in the event of a malfunction. Fault codes can be diagnosed using Land Rover approved diagnostic equipment.

Linear Clutch Sensor

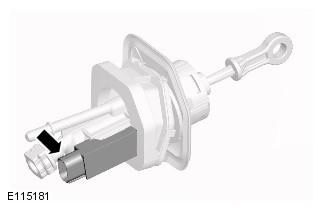

To ensure timely restart of the engine in the cycle "Stop/Start" in changeable city driving conditions, the engine starts within approximately 800 milliseconds. This is achieved with a linear clutch sensor that initiates a restart of the engine when the clutch pedal is at the starting point of down travel. Therefore, while the clutch pedal is moving down, the engine restart procedure is already in progress.

Linear clutch sensor is a type of PLCD sensors (non-contact permanent magnet linear displacement sensors) and is located on the clutch master cylinder and wired to the CJB. The sensor constantly sends a signal to the CJB about the position of the clutch pedal; this information is sent to the ECM via the high speed CAN bus. The move start point signal is used to enable the motor to restart automatically if all other prerequisites are met.

The linear clutch sensor also provides a signal for the final (bottom) travel point when the clutch pedal is near the lowest point. This signal is used when the engine stalls and permission to start is required. This is a unique feature that automatically restarts the engine when other prerequisites are met. See section "Restarting a stalled engine" below.

The clutch pedal position sensor receives information about the position of the clutch pedal from a magnet in the clutch master cylinder. Therefore, in case of replacement of the master cylinder, it must be correctly selected and installed.

The two existing clutch pedal position sensors, located on the clutch pedal and transmitting signals to various vehicle systems, are also used by the system "Stop/Start" to check the validity of the signals.

If the linear clutch sensor fails, a DTC is stored in the CJB.

NOTE: System "Stop/Start" will not work properly if the driver constantly keeps his foot on the clutch pedal while driving.

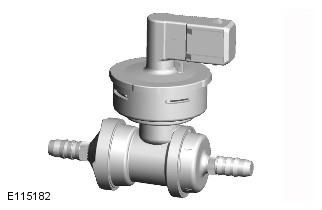

Brake booster vacuum sensor

To ensure that the braking system is always operational, on vehicles with "Stop/Start" a brake booster vacuum sensor is installed, which monitors the presence of vacuum in the brake servo. The vacuum sensor is installed in the vacuum tube and wired to the ECM. If the vacuum in the brake system in the cycle "Stop/Start" falls below a predetermined threshold, the ECM issues one of the following signals:

- Restart the engine and keep the vacuum condition at all times.

- Block the engine shutdown if the vacuum level is insufficient.

An example of a reduced vacuum is when the driver periodically presses the brake pedal with the brake off in the cycle "Stop/Start" engine. This action will restart the engine if the vacuum level falls below the set threshold.

If the brake booster vacuum sensor fails, a DTC will be stored in the CJB.

Auxiliary coolant pump

During the cycle «Stop/Start», when the engine is off and therefore the coolant pump is not operating, it is not possible to maintain the set temperature in the passenger compartment for a long time, especially at low ambient temperatures. To solve this problem, an auxiliary electric coolant pump has been added to the cooling system, which ensures the passage of liquid through the passenger compartment heater radiator. This auxiliary circulation allows you to extend the maintenance of the desired temperature in the cabin and prevents premature restart of the engine.

Depending on the vehicle class, the auxiliary coolant pump can be:

- Wired to ECM.

- Or if the vehicle is equipped with FFBH (fuel-fired auxiliary heater), an FFBH coolant pump activated via the FFBH can be used.

The functions of both types of auxiliary coolant pumps are the same as far as the system is concerned "Stop/Start".

To muffle the sound of the auxiliary pump being turned on, it is activated at the same time as the engine is turned off.

Remote control

For the convenience of the driver, a new remote control extraction system has been developed. This allows the driver to instantly remove the remote control from the launch control box when the engine is off in a cycle "Stop/Start".

If the system "Stop/Start" turned off, the standard procedure for removing the remote control begins: by pressing the ignition on/off button before removing the remote control.

Starting the engine after it has stalled/switched off

If the engine stalls, the system "Stop/Start" enters a unique restart mode. This feature will automatically attempt to restart the engine when the driver fully depresses the clutch pedal, a natural driver reaction when the engine is stalling.

When the clutch pedal position sensor detects the low pedal travel threshold (see "Linear Clutch Sensor"), the starter is activated to start the engine. Instrument panel warning lights usually associated with an engine shutdown (e.g. ignition and low oil pressure indicators), in this case are blocked and not enabled. The Eco indicator remains on.

Event "restarting a stalled engine" is the only state in which the system "Stop/Start" allows the engine to start with the gear engaged; hence the requirement to fully depress the clutch pedal. If the restart fails and the engine does not start, the information panel displays the message "turn on neutral" to retry the restart.

If restarting a stalled engine fails after this request, this restart mode will time out and turn off. At the same time, the icon "Eco" on the instrument panel will turn off and the warning lights, usually indicating a stalled engine, will turn on. As a result, the driver must follow the standard procedure for restarting the engine.

Although restarting the engine is a function of the automatic system "Stop/Start", it can be activated regardless of the settings "Stop/Start". For example:

- If the automatic system "Stop/Start" has been turned off by the driver, the restart function will still be active.

- The restart function is activated at ambient temperatures down to -2°C, while the operating temperature threshold of the system "Stop/Start" - above 4°C.

- Unlike the automatic system "Stop/Start" the restart function will keep working when towing; see section "Trailer towing".

NOTE: Since the required criteria are not met when the vehicle starts moving, the restart function does not work. For example, if the car stalls while exiting the garage or driveway, you will need to restart the engine in the normal way.

Trailer towing

System "Stop/Start" automatically turns off if the CJB detects trailer lighting from signals from the trailer module; this information is then transmitted to the ECM. The system cannot detect when the trailer power cable is connected to the vehicle socket, so it uses the trailer lights as an indicator.

Trailer towing system blocks the automatic system "Stop/Start", since it is possible that the trailer's power consumption may interfere with the operation of the battery monitoring system. In particular, the trailer battery can generate reverse current during engine start. This is fraught with the following consequences:

- mislead the battery monitoring system, which will detect an implausibly low current when the engine is started

- disable the trailer module fuse

Climate control system

NOTE: Button "ECON" was renamed to "A/C", to exclude the possibility of confusing it with a button "Eco" systems "Stop/Start".

A number of corrections were also made to the logic and operation of the microclimate control system in the cycle "Stop/Start":

- maintaining the comfort of the driver and passengers

- windshield fogging prevention

- saving battery power

This is achieved by means of control of the ATC unit (automatic climate control) and, if necessary, changing the various climate control functions in the Stop/Start cycle.

In some cases, ATC may block the engine from shutting down or initiate it to restart in a cycle "Stop/Start". This is achieved by exchanging data between the ATC module and the CJB over the medium speed CAN bus. The following is a description of the various blocking functions in ATC for a loop "Stop/Start":

Coolant temperature

The ATC module blocks an engine shutdown or initiates an engine restart in a cycle "Stop/Start", if the coolant temperature falls below the calculated threshold to ensure that the set cabin temperature is maintained.

Defogging the windshield

Modification of the climate control system determines the changes made to the program control. For example, the basic climate control system is not equipped with a humidity sensor that initiates windshield blowing in high-level systems. Therefore, the calculation of the removal of fogging of the windshield is carried out according to the signals from the rain sensor and the ambient air temperature sensor. Given the possibility of fogging the windshield during rain and low ambient temperatures, ATC assumes the need to remove the fogging of the glass and starts the engine in a cycle "Stop/Start".

The evaporator temperature is also monitored - the main cause of windshield fogging - and the high-level climate control system periodically cools the evaporator if necessary to reduce fogging in the cycle "Stop/Start". The system activates the windshield demist damper, and if there is high humidity in the evaporator, the damper remains closed for a few seconds after the engine is restarted, until the fumes are removed.

If the driver selects "programmed defrost" (programmable defrost) or "windshield heater" (windscreen heater), it is assumed that a quick cleaning of the windshield is required. In this case, the ATC will perform one of the following actions via the CJB: block the engine shutdown or initiate the engine start.

Heater fan speed

When the engine is off, ATC monitors the temperature in the passenger compartment and maintains the fan speed at the level required to retain heat in the passenger compartment heater radiator as long as possible. If the driver turns on the increased fan speed and it is not possible to keep the heat in the heater core, the engine will be restarted.

Heated rear window and heated seats

If the heated rear window or heated seats are on, or if they are activated when the engine is turned off, power to the respective system will be cut off until the engine is restarted. The indicator on the corresponding switch will illuminate to indicate that the system is active, even if the system is not receiving power. This feature is used to conserve battery power.

Fuel fired heater

FFBH (fuel-fired auxiliary heater) and system "Stop/Start" cannot work at the same time, since low ambient temperature is a factor taken into account in both systems.

Hood open warning switch

WARNING: To prevent personal injury when repairing vehicles, be sure to disable the automatic system "Stop/Start" at the touch of a button "ECO"; make sure the information bar shows a message "System "Stop/Start" off", and the ECO indicator in the switch is off.

The hood open warning switch wired to the CJB has two functions:

- Serves as an engine shutdown interlock, allowing the engine to run when the hood latch is not closed.

- Turns off the system "Stop/Start" when the engine is stopped; the result is a stalled engine condition. The engine can be restarted by pressing the ignition button. In this case, the restart of the stalled engine does not occur; see section "Restarting a stalled engine".

After closing the hood, the automatic system "Stop/Start" activated by restarting the engine manually.

System failure

System "Stop/Start" automatically activated each time the ignition is turned on; the operation of the system is indicated by the inclusion of an indicator in the switch "Eco". If the indicator does not turn on, this indicates a malfunction of the system or its unavailability. Message "ECO STOP/START FAULT" (System start "Stop/Start" using the button "ECO" does not work) appears on the information panel only if the driver tries to activate the system by pressing a button "Eco".

Due to the complexity of the system "Stop/Start", because many other modules and communication networks in the vehicle are involved in this function. When investigating system faults "Stop/Start" it is recommended to pre-diagnose and eliminate the malfunctions of all other systems, as they may affect the performance of the system "Stop/Start".

DTC (diagnostic trouble code) systems can be diagnosed using Land Rover approved diagnostic equipment.

Comments on this article