A turbocharged engine offers the following advantages over a conventional direct intake engine:

- Higher volumetric efficiency

- Increased engine power and torque

- Reduced fuel consumption

- Emission reduction

- Use of energy from exhaust gases

- No dependence on altitude

- Limited boost periods for immediate engine requests

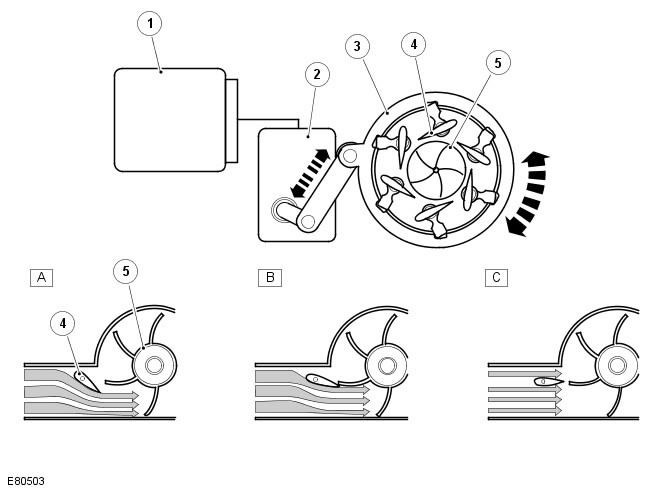

A typical turbocharger driven by a rotating electronic actuator:

| Pos. | spare part no | Name |

| A | - | Low engine crankshaft speed |

| B | - | Average engine speed |

| C | - | Maximum engine speed |

| 1 | - | ECM |

| 2 | - | Rotating electronic actuator |

| 3 | - | Rotating adjusting ring |

| 4 | - | Adjustable paddles |

| 5 | - | turbine wheel |

Responding to signals from various sensors, the ECM controls the REA to actuate the rotating adjusting ring. Moving the adjusting ring changes the angle of the adjustable vanes to divert the exhaust flow towards the inner center or outer edge of the turbine wheel.

Maximum position of adjustable turbocharger vanes (fully open position) is also the default emergency position in case of an electrical problem. REA will move the adjustable vanes to the fully open position to prevent engine damage due to increased boost pressure.

A - low engine speed

When the engine speed is low, the volume of exhaust gases leaving the engine is low. The vanes move to the closed position to direct the exhaust gas flow towards the outer edge of the turbine wheel. The closed position of the blades reduces the throughput for the flow of gases and increases the speed of the gases going to the turbine wheel. The speed of the turbine wheel increases, correspondingly increasing the amount of charge air (boost pressure), supplied from the compressor.

B - Average engine speed

As the engine speed and exhaust gas volume increase, the vanes move to the open position to direct the exhaust gas flow towards the center of the turbine wheel. The blades do not restrict the flow of exhaust gases and therefore the speed of the gases depends on the speed of the engine crankshaft. The speed of the turbine wheel is maintained by increasing the velocity of the gases exiting the engine and directed towards the central region of the turbine wheel.

C - Maximum engine speed

At maximum engine speed, the volume of exhaust gases leaving the engine is high. The vanes move towards the fully open position and do not affect the gas velocity. The exhaust gas flow contacts the central region of the turbine wheel to maintain the speed of the turbine wheel and boost pressure from the compressor.

Increased boost pressure

During medium-to-hard acceleration, the turbocharger must build up boost pressure for a limited period of time to meet the current fuel requirements of the engine. The ECM will request REA to move the variable vanes to the closed position to increase the speed of the turbine wheel already spinning at high speed. The boost pressure condition is tolerated by the ECM for a limited period.

Barometric pressure sensor

At high altitudes, the turbocharger will operate normally, but due to the lower outside pressure, the turbine and compressor may tend to overspeed. The ECM contains a barometric pressure sensor to prevent excessive boost pressure and possible engine damage under these conditions. The ECM opens the variable vanes earlier in the opening phase to suit vehicle altitude conditions.

Turbocharger lubrication

The fast acceleration and deceleration requests of the turbocharger depend on the stability of clean oil flow. The oil supplied by the engine lubrication system lubricates the turbocharger shaft and bearings while also acting as coolant for the turbocharger center housing.

To maintain the expected life of the turbocharger, the engine oil should be changed at regular service intervals using the recommended quality oil in the required quantity. The oil must have a free passage through the turbocharger and the possibility of an unrestricted return to the oil sump.

Comments on this article