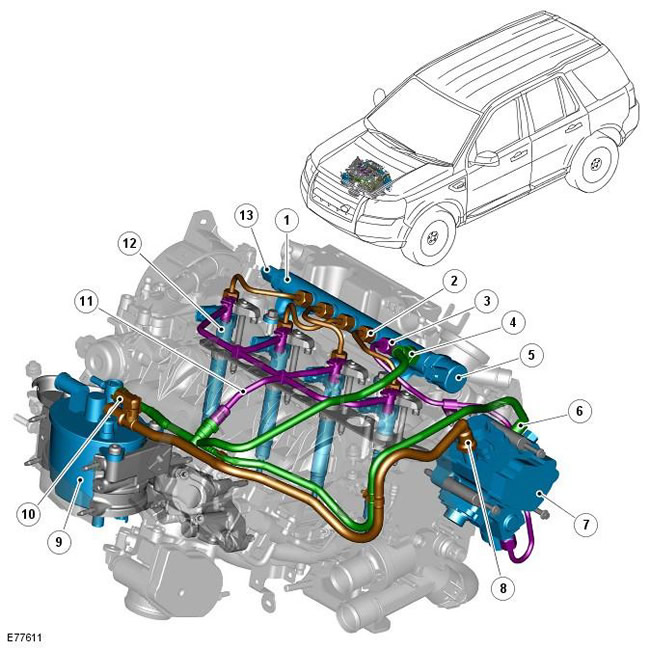

| Pos. | spare part no | Name |

| 1 | - | Common fuel manifold |

| 2 | - | High pressure pipeline - from the fuel manifold to the nozzle (4 things.) |

| 3 | - | High pressure pipeline - from the pump to the fuel manifold |

| 4 | - | Pipeline - pressure relief in the fuel manifold |

| 5 | - | Fuel rail pressure control valve |

| 6 | - | Hose - bypass, high pressure pump |

| 7 | - | High pressure fuel pump |

| 8 | - | Low pressure hose - from fuel filter to pump |

| 9 | - | Fuel filter assembly |

| 10 | - | Fuel temperature sensor |

| 11 | - | Pipeline - bypass, injectors |

| 12 | - | Nozzle (4 things.) |

| 13 | - | Fuel rail pressure sensor |

The TD4 diesel engine's fuel delivery and control system delivers precise and instantaneous fuel to the combustion chambers. This ensures optimal dynamic performance and excellent engine response to driver commands in all driving conditions. The fuel system includes a Bosch common rail injection system that is monitored and controlled by (engine control module) (ECM), designed for precise control of the fuel delivery strategy.

Fuel is supplied by a low and high pressure fuel system. The low pressure fuel system includes the following elements:

- saddle shaped fuel tank

- tank-mounted fuel delivery module with integrated transfer pump

- supply and return fuel lines

- filter and water separator assembly

- connecting hose between fuel filter assembly and fuel lift pump

NOTE: The fuel lift pump is combined with the high pressure pump.

The remaining elements of the fuel return circuit of the low pressure system are the return pipeline and fuel bypass hoses from the high pressure pump, injectors and the common fuel manifold. For more information see the chapter: Fuel Tank and Lines - 2.2L Duratorq-TDCi (DW) Diesel (310-01 Fuel Tank and Lines, Description and Operation).

The high pressure fuel system includes the following elements:

- high pressure fuel pump

- common fuel manifold

- 4 piezo nozzles with high pressure connecting pipes

- fuel pressure sensor

Fuel supply and control system provides injection pressure up to 1800 bar (26.106 psi). Finer atomization of the injected fuel is provided by piezo injectors with 7 holes, which are able to almost instantly respond to ECM commands, producing up to 5 separate injections per stroke.

The high pressure fuel pump is mounted behind the cylinder head and is driven by the exhaust camshaft. The fuel lift pump is integrated with the high pressure pump and is therefore also driven by rotation of the exhaust camshaft. The lift pump creates a suction effect in the supply line to the fuel tank and pumps the fuel out of the tank. The fuel passes through the fuel filter and is then delivered at the pressure generated by the lift pump to the inlet port of the high pressure pump.

The upgraded high pressure fuel system provides for the possibility of pilot injection, which occurs before the main fuel injection. This creates a stable flame front and a progressive pressure increase in the cylinder, similar to the process that occurs in gasoline engines. This shortening of the ignition delay between the moment of fuel injection and the moment of ignition ensures that fuel is injected during combustion, thereby increasing power and reducing (noise, vibration and harshness) (NVH) and emission levels.

On models equipped with a diesel particulate filter, the high pressure fuel system also provides after injection of fuel into the combustion chambers. When a request is made to regenerate the diesel flue filter, the ECM allows the fuel system to deliver fuel after the combustion stroke and at the beginning of the exhaust stroke. This post-injection process burns the fuel in the exhaust system and generates the high exhaust gas temperatures required for filter regeneration.

Comments on this article