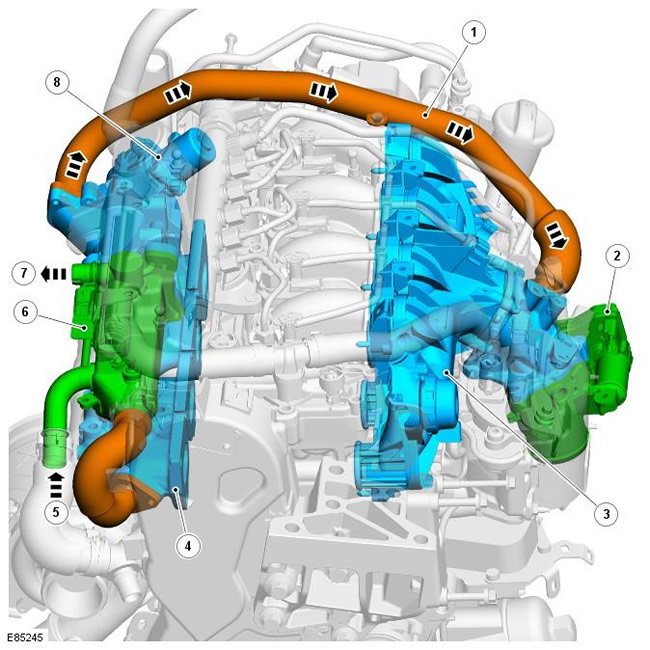

| Pos. | spare part no | Name |

| 1 | - | Exhaust gas connecting pipe - with indication of flow direction |

| 2 | - | throttle body |

| 3 | - | Intake manifold |

| 4 | - | An exhaust manifold |

| 5 | - | coolant inlet |

| 6 | - | Exhaust gas recirculation system heat exchanger (EGR) |

| 7 | - | coolant outlet |

| 8 | - | Exhaust gas recirculation valve and actuator (EGR) |

During the reaction between oxygen and nitrogen at high temperatures, harmful oxides of nitrogen are formed (NOx), which are part of the exhaust gases. Reducing the temperature in the combustion chamber of the engine, and therefore the amount of NOx produced, is achieved by recirculating part of the exhaust gases. Exhaust gas recirculation replaces some of the air entering the engine, as this reduces the oxygen content in the cylinders and lowers the maximum combustion temperature by several hundred degrees.

To reduce the temperature as well as to increase the density of the injected fuel charge, the recirculated exhaust gases pass through an exhaust gas recirculation heat exchanger (EGR). The EGR heat exchanger uses coolant from the engine's cooling system to reduce the temperature of the exhaust gases. The exhaust gases entering the EGR heat exchanger reach a temperature of approximately 500 degrees C. The EGR heat exchanger reduces the temperature of the gases to 250-300 degrees C before the gases exit it.

Work principles

Electrically actuated valve mounted on the outlet side of the EGR heat exchanger and controlled by the powertrain control module (PCM), regulates the amount of exhaust gases recirculated to the air intake system. The PCM uses signals from various engine sensors and calculates the response based on a software algorithm to control the EGR. The PCM sends this control signal to the valve actuator, which is controlled in closed loop mode by the mass air flow sensor (MAF), providing feedback to the PCM.

Comments on this article