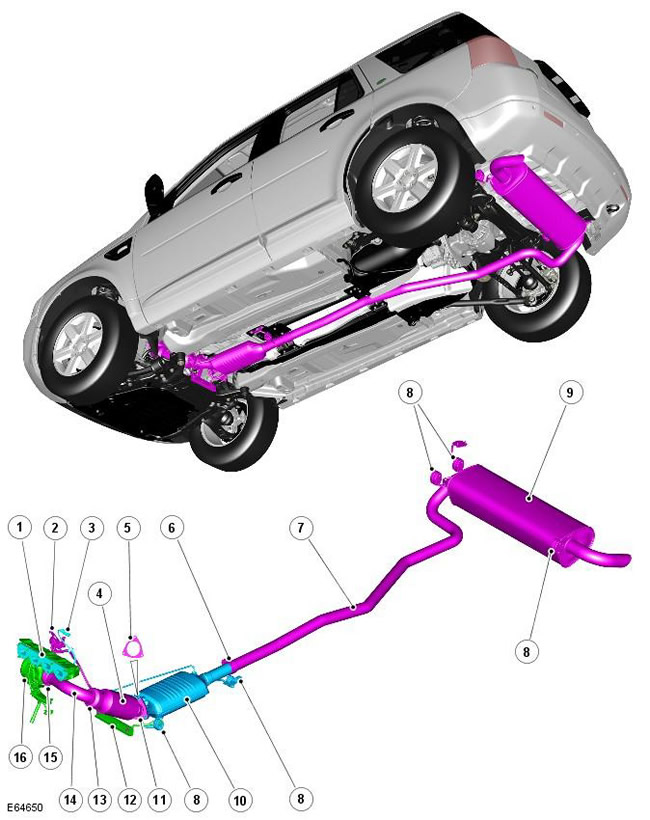

With particulate filter

| Pos. | spare part no | Name |

| 1 | - | An exhaust manifold (for reference only) |

| 2 | - | Differential pressure sensor |

| 3 | - | Heated oxygen sensor (HO2S) (for reference only) |

| 4 | - | catalytic converter |

| 5 | - | Pad |

| 6 | - | clamp "Torca" |

| 7 | - | Connecting pipeline |

| 8 | - | rubber support (6 pcs.) |

| 9 | - | Rear silencer |

| 10 | - | Diesel Combustion Filter (DPF) |

| 11 | - | Flange |

| 12 | - | Body suspension |

| 13 | - | Release device |

| 14 | - | outlet elbow |

| 15 | - | 'V' clamp and gasket |

| 16 | - | Turbocharger (for reference only) |

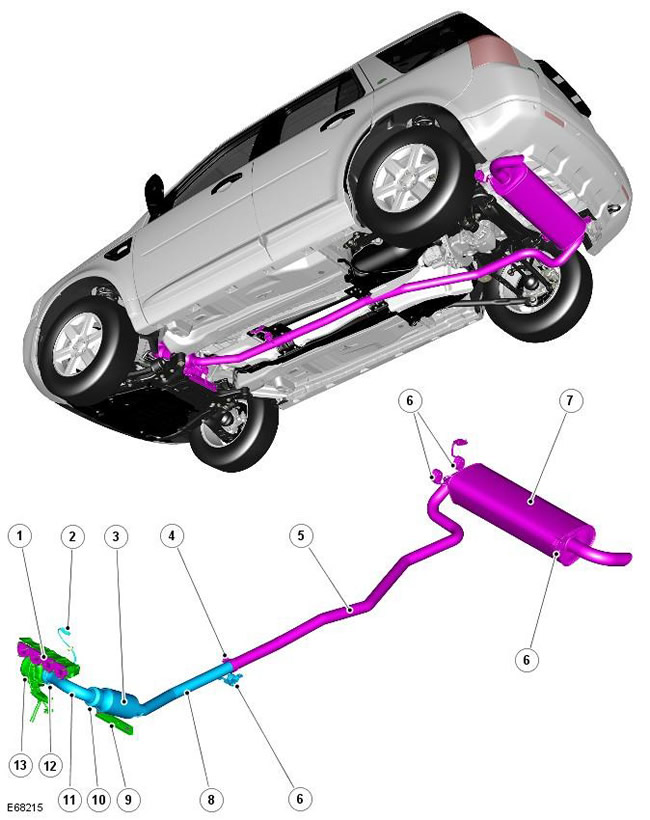

Without particulate filter

| Pos. | spare part no | Name |

| 1 | - | An exhaust manifold (for reference only) |

| 2 | - | HO2S (for reference only) |

| 3 | - | catalytic converter |

| 4 | - | Hinge "Torca" |

| 5 | - | Rear connecting pipeline |

| 6 | - | rubber support (5 pieces.) |

| 7 | - | Rear silencer |

| 8 | - | Front connecting piping |

| 9 | - | Body suspension |

| 10 | - | Release device |

| 11 | - | outlet elbow |

| 12 | - | "V"-clamp and gasket |

| 13 | - | Turbocharger (for reference only) |

The 2.2L DW12 exhaust system is made of stainless steel and consists of 2 separate assemblies; the front section houses the catalytic converter, and the rear section houses the rear muffler.

Some markets have a diesel particulate filter in the exhaust system (DPF), thanks to which the car exceeds the requirements for exhaust toxicity Euro IV.

The system is fixed to the bottom of the body with 6 rubber mounts (in vehicles without DPF - 5 rubber mounts), which are located on mild steel brackets welded to the system. The rubber feet are used to position the brackets, which are welded or bolted to the underbody.

Front section

The front section has a flared end that mates with the corresponding turbocharger element. The connection is fixed with "V"-shaped clip and sealed with a gasket.

The outlet elbow assembly has a stamped flange and is welded to the release device. The elbow has a threaded lug for mounting the HO2S. A release device providing flexible articulation is welded to the catalytic converter housing.

Vehicles without DPF

A short section of the front connection pipe coming from the catalytic converter mates with the rear system connection pipe and is secured with a hinge "Torca". The rubber mount is located next to the catalytic converter and is attached to the body hanger bracket.

Vehicles with DPF

The catalytic converter has a flange connection sealed with a gasket and mating with the DPF flange. Out of the DPF outlet is a short section of the front connection piping that mates with the system's rear connection piping and is secured with a flanged connection. Two rubber mounts are located next to the catalytic converter and are attached to the body hanger bracket.

Rear section

The rear section has a long connecting piping that mates with the front connecting piping coming from the catalytic converter or DPF and is attached with a hinge "Torca". The pipe section runs along the underside of the vehicle and connects to the right side of the rear muffler.

The rear muffler is a 29.3L prefabricated unit. Inside the muffler there are baffles and perforated tubes that reduce noise when the exhaust gas passes through the muffler. Exhaust gas enters the muffler on the right side and exits through a pipe on the left side. The rear exhaust pipe faces the rear of the vehicle and is bent downwards to carry exhaust gases away from the vehicle.

Catalytic converter

An oxidizing catalytic converter with a capacity of 2 liters is installed in the front section of the exhaust system, after the HO2S. Vehicles with and without DPF use an identically designed catalytic converter.

The HO2S sensor is used to monitor the composition of exhaust gases from the engine. The engine management system uses information from the sensor to precisely dose fuel into the combustion chamber to maximize fuel efficiency and minimize emissions.

To further reduce the content of carbon monoxide and hydrocarbons in the exhaust gases, a catalytic converter is integrated into the front exhaust pipe. In the catalytic converter, the exhaust gases pass through honeycomb ceramic elements with a special surface treatment ("washcoat").

Treatment "washcoat" increases the surface area of ceramic elements by about 7000 times. over "washcoat" a coating containing platinum is applied - this is an active component that serves to convert harmful waste products into inert substances. Platinum adds oxygen to the carbon monoxide and hydrocarbons found in the exhaust gases, converting them to carbon dioxide and water, respectively.

Comments on this article