NOTE: When reference is made to "suitable equipment", this applies to the standard equipment of the service station. Refer to the operating instructions for your own equipment when performing any checks.

Pinpoint test A: cylinder compression test

WARNING: Only compression gauges capable of reading the higher compression pressures present in diesel engines should be used. Failure to follow this instruction may result in injury.

NOTE: If possible, the compression test should be performed at normal engine operating temperature.

A1: Compression test in engine cylinders ("dry")

- Apply the parking brake and move the selector lever to the neutral position (or engage park gear on vehicles with automatic transmission).

- Turn off the ignition (OFF).

- Remove the starter relay.

- Disconnect the starter solenoid electrical connector.

- Connect a suitable remote start device to the starter solenoid.

- Remove glow plugs. For more information refer to: Glow Plugs (303-07B Glow plug system, Removal and installation).

- Install a suitable adapter in place of the glow plug in the first cylinder to be tested.

- Connect a suitable tester to the adapter. See warning above.

- Using the remote starter, crank the engine through at least five revolutions.

- Write down the compression pressure and the speed at which it is reached.

- Repeat the steps in p.p. 7 - 10 higher for the remaining cylinders, cranking the engine the same number of revolutions each time.

- Compare compression pressure readings for all cylinders.

Yes - If compression readings are not very low for natural reasons (experience will point it out), check for other reasons for the customer's complaint. No - GO to A2.

A2: Compression test in engine cylinders ("wet")

CAUTION: If engine oil is being injected into the cylinders, allow the engine to run at 2,000 rpm for at least 10 minutes after the check is complete to prevent damage to the catalytic converter. Failure to follow this instruction may result in damage to the vehicle.

NOTE: There is a combustion chamber at the top of each piston. Take care that no oil enters this chamber.

- Using a suitable can of oil with a long flexible nozzle, immediately before checking, inject a small amount of clean engine oil into the cylinder so that the oil fills the gap between

- piston and cylinder.

- Repeat the steps in p.p. 7 - 10 of the test described above, immediately before the test, introducing oil into each cylinder.

- Compare compression pressure readings for all cylinders.

Yes - Higher readings after oil injection may indicate wear or damage to the cylinder, piston and/or piston rings. To verify this, disassembly is required.

No - If the compression pressure remains unchanged after the oil was added, but the reading is still less than 90% of the reading for other cylinders, this may indicate valve sticking and / or sticking, head gasket leaks, etc. To verify this, disassembly is required. Erase any DTCs that may have been triggered by the test.

Pinpoint test B: oil consumption test

NOTE: Oil consumption varies depending on a number of factors. New engines usually use more oil than "run-in" engines, after the flow rate has been determined. For more information, contact your dealer's technical support.

B1: check for excessive oil consumption

- Start the motor and let it run until it reaches normal operating temperature.

- Park the vehicle on level ground and turn off the engine.

- Give the car "hold out" for at least five minutes.

- Check the oil level.

- If necessary, correct the level and record the readings and mileage in the vehicle's service book.

- Inform the owner/driver that a check is in progress and he should not add oil while the check is in progress, but should check the level every 160-240 km.

- When the oil level reaches the ADD mark, the customer must bring the vehicle to a workshop for inspection.

- Add oil to the level appropriate for the start of the test and record the amount of oil needed to do so and the mileage covered during the test.

- Based on this, you can calculate the expense and decide whether the expense is really recognized as increased.

Yes - Requires disassembly to check the items listed in the symptoms table.

No - No further action required.

Pinpoint test C: check engine oil pressure

NOTE: The vehicle must be driven at least 10 km before checking the oil pressure. Do not attempt to reach normal operating temperature by letting the engine idle.

NOTE: Before starting this check, check the engine oil level and add oil as needed.

C1: check for insufficient engine oil pressure

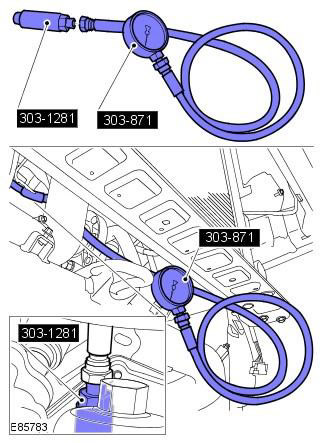

- Remove the oil pressure sensor. For more information refer to: Engine Oil Pressure Sensor (EOP) (303-14B Electronic controls - 2.2L Duratorq - Td4, Removal and installation).

- Connect an oil pressure gauge and adapter in place of the oil pressure gauge.

- Start the engine and check for leaks at the pressure gauge connection.

- Let the engine idle and check the oil pressure.

- Increase the engine speed to 4000 rpm and check the fuel pressure.

Yes - The presence of these pressure values does not indicate a malfunction, the oil pressure is considered normal.

No - Low pressure may indicate problems in such elements / parameters as: oil pump, filtration, gaps in the engine. Check for any other signs of engine trouble (noise, etc). High pressure may indicate a blockage in the lubrication system. If this problem is not resolved, high oil pressure will lead to engine oil leaks and other problems.

Comments on this article