The lubrication system receives oil from the oil sump, oil is supplied under pressure. Oil lubricates the surfaces of moving engine parts, dissipates heat, absorbs fuel combustion products and seals the gap between the cylinder and the piston.

The engine is lubricated through a pressure lubrication system using a full flow oil filter and oil cooler assembly. The oil filter and radiator form a single unit mounted on the left side of the cylinder block, next to the oil pump. The engine oil is cooled by the engine cooling system, so no additional separate oil cooler is required.

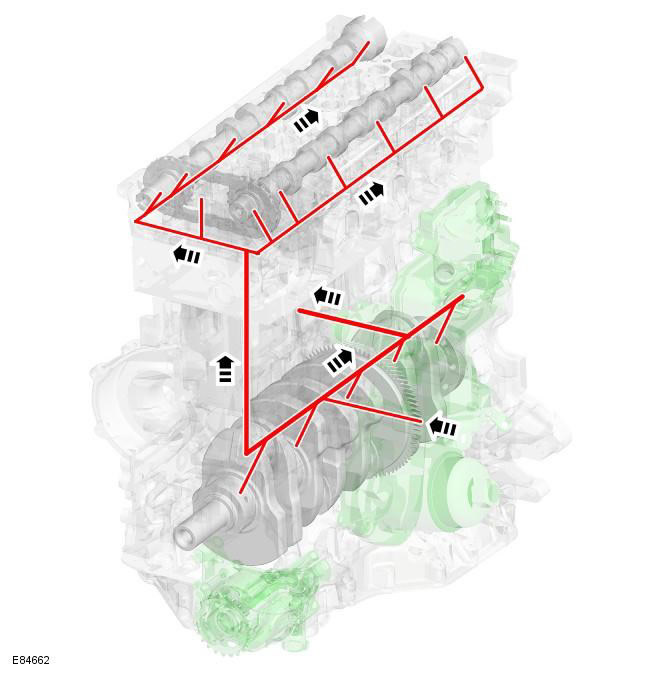

Oil is taken from the oil sump and pressure is generated by an oil pump driven by the crankshaft. At the outlet of the oil pump, filtration and cooling takes place, then the oil enters the main oil gallery of the cylinder block. Through drilled channels and galleries connected to the main oil gallery, oil under pressure enters the cylinder block and to the bearings of the cylinder head elements, which perform a reciprocating motion. Through the hole above the No. 3 main bearing cap, pressurized oil enters a port located on the rear right side of the cylinder block. Through this port pressurized oil, through a nipple type connection "banjo" and pipeline, fed to the bearings of the turbocharger.

Lubrication of all moving parts of the engine is carried out by supplying oil under pressure, or by spraying oil. Pressurized oil is also supplied to the hydraulic lifters and timing chain tensioners.

The oil returns to the oil sump by gravity. Large drain holes molded into the cylinder head and cylinder block ensure fast oil return.

The lubrication system is replenished through the oil filter cap, which is located on the soundproof engine cover. The oil dipstick is located on the left side of the oil sump. The two marks on the end of the dipstick correspond to the minimum and maximum oil levels. The difference between the maximum and minimum levels indicated by the marks is 1.5 liters of oil.

Comments on this article