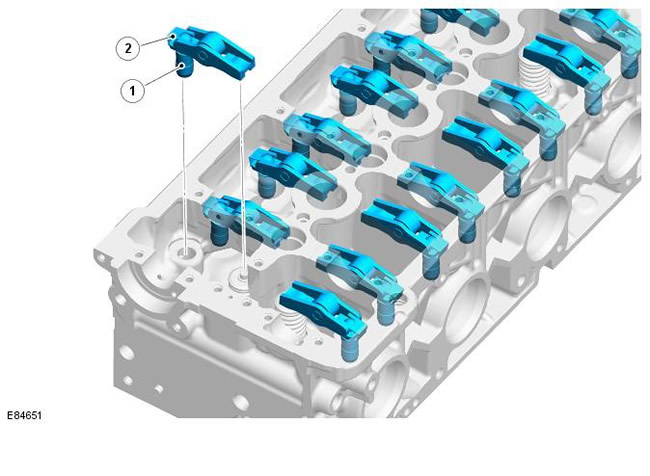

| Pos. | spare part no | Name |

| 1 | - | Hydraulic gap compensator |

| 2 | - | Roller valve lever |

The 16 valves are actuated by roller valve levers and hydraulic lash adjusters, which in turn are actuated by camshaft lobes. One end of the valve lever rests on the end of the valve stem, the other end is attached to the hydraulic lash compensator. In the center of the valve lever is a roller that stays in contact with the camshaft cam.

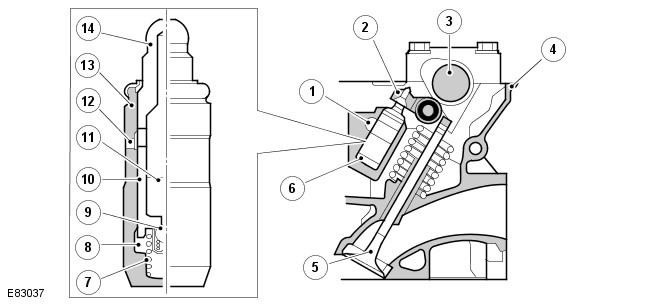

Typical hydraulic lash adjuster

| Pos. | spare part no | Name |

| 1 | - | oil channel |

| 2 | - | Roller valve lever |

| 3 | - | Camshaft |

| 4 | - | cylinder head |

| 5 | - | Valve |

| 6 | - | Hydraulic gap compensator |

| 7 | - | plunger spring |

| 8 | - | High pressure chamber |

| 9 | - | ball valve |

| 10 | - | Plunger |

| 11 | - | reservoir chamber |

| 12 | - | oil channel |

| 13 | - | Hydraulic clearance compensator housing |

| 14 | - | plunger cap |

When moving, the camshaft cam presses on the roller valve lever and, therefore, the force acts on the hydraulic lash adjuster and valve train. The corresponding valve is pressed against the pressure of the valve spring, the hydraulic plunger is also pressed into the oil chamber in the cylinder head. This valve actuation mechanism minimizes friction between valve operating elements and eliminates the need for mechanical adjustment.

The body of the hydraulic gap compensator contains a plunger and two chambers for oil supply and for pressurized oil. Pressurized oil is supplied to the gap compensator through an oil gallery in the cylinder head and through an opening in the side of the gap compensator housing. The oil passes into the supply chamber of the gap compensator and then into a separate pressure chamber through a one-way ball valve.

The oil flow from the pressure chamber is determined by the gap between the outer housing and the central plunger of the gap compensator. With each actuation of the gap compensator, oil flows out along the wall of the plunger. The pressure pressing down on the plunger displaces the appropriate amount of oil in the lash adjuster housing.

With further rotation of the camshaft cam, the force acting on the camshaft and valve lever is removed. The gap compensator plunger is pushed upward by the pressure of the oil in the pressure chamber. This pressure is not enough to affect the operation of the valve, but enough to eliminate the gap between the valve lever and the top of the valve stem.

Comments on this article