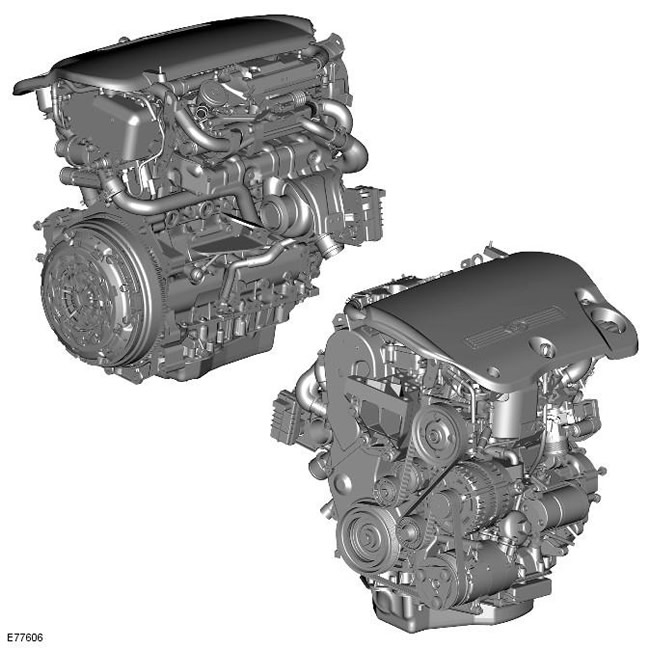

NOTE: Freelander 2 vehicles use the new TD4 diesel engine. This TD4 diesel engine was not previously used by Land Rover and cannot be mistakenly identified with the Td4 diesel engine used in the previous Freelander.

The new TD4 diesel engine may also be referred to or referred to in text as the 2.2L Duratorq-TDCi (DW).

The TD4 diesel engine is a 2.2L inline 4-cylinder engine with a DOHC layout (with two overhead camshafts) and four valves per cylinder. The valves are actuated by roller valve levers and hydraulic lash adjusters. Air and diesel fuel are delivered to the cylinders by means of an adjustable nozzle tube compressor (VGT), which is electronically controlled, and the 3rd generation Bosch fuel system with fuel manifold type "common rail".

Engine monitoring and optimum efficiency ensured by the electronic engine management system and the engine control module (ECM) Bosch.

The motor is a compact unit that takes up minimal space. It is designed to improve performance in terms of noise, vibration and harshness (NVH). The reduced size of the engine allows for a high level of pedestrian protection and meets vehicle performance standards in high-speed collisions.

The engine is designed with a precision machined die-cast aluminum alloy cylinder head and a laminated metal head gasket. The head is securely bolted to a machined cast iron cylinder block. There are 16 valves in the cylinder head (4 per combustion chamber), valve train, camshafts and gas distribution mechanism, fuel injectors and glow plugs. The cylinder head has drilled holes and passages for lubricating oil and coolant.

The cylinder head is integrated with cast lower camshaft bearing caps and sealed by a mating gasketed camshaft cap. The camshaft cover is integrated with cast camshaft bearing caps and has intake air passages, cylinder head cover ports, and crankcase ventilation components.

The 'L'-shaped cylinder head cover has structural holes for the camshaft cover. It has a built-in crankcase ventilation valve (PCV), relief valve and crankcase ventilation connections.

A soundproof engine cover is installed above the engine, it has a layer of polypropylene foam glued to the back of the thermoplastic cover. The cover is designed to absorb and reduce engine noise down to acceptable NVH levels. The hole in the rear left side of the engine cover is designed to accommodate the engine oil filler cap.

The crankshaft and bearings, nozzles for oil cooling, elements of the crank mechanism and the shaft housing of the balancing system are located in the cylinder block. The cylinder block is provided with holes and channels for lubricating oil and coolant. The balance shaft housing is bolted to the underside of the cylinder block and driven by a gear train from the crankshaft. The balancing system improves the NVH performance of the engine, ensuring smooth operation.

An aluminum oil sump and a pressed steel oil sump are attached to the bottom of the cylinder block. The oil sump housing is sealed and bolted directly to the cylinder block. The oil sump is sealed with a liquid sealant and attached to the oil sump housing to form a reservoir for the lubrication system. Inside the oil sump is the lubrication oil pump, which is bolted to the underside of the cylinder block. The oil pump is driven by a chain from the crankshaft.

The engine is cooled by a pressurized cooling system that uses coolant as the working medium. The engine-driven coolant pump distributes coolant through channels in the cylinder head and cylinder block.

The toxicity of the exhaust gases of the engine complies with the regulatory requirements of the Directive of the European Commission (EUCD) 4th stage. Limiting the resulting emission of toxic products is achieved through the use of an exhaust system catalytic converter, an optional diesel particulate filter (DPF), improved electronic engine management, PCV and EGR (EGR).

Comments on this article