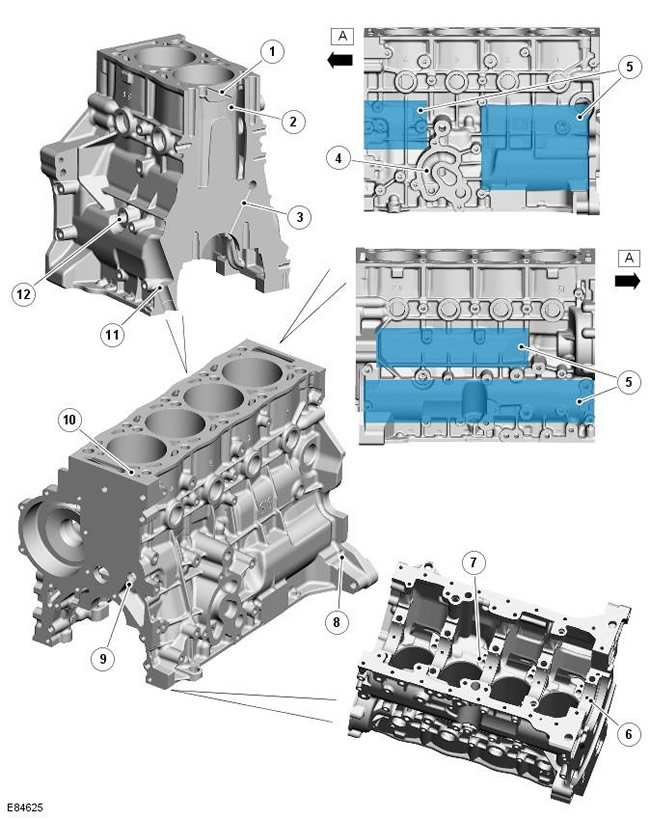

| Pos. | spare part no | Name |

| A | - | Front of the engine |

| 1 | - | Expansion chamber opening |

| 2 | - | coolant chamber |

| 3 | - | Hole for supplying oil to the main bearings |

| 4 | - | Oil filter housing |

| 5 | - | Double wall (dark areas) |

| 6 | - | Oil supply port for main bearings |

| 7 | - | Oil nozzle installation port |

| 8 | - | Installation location of the special tool for adjusting the ignition timing |

| 9 | - | Main oil gallery |

| 10 | - | Oil supply port to cylinder head |

| 11 | - | Return oil port VGT |

| 12 | - | Supply oil port VGT |

The cylinder block is made of cast iron and has two-layer walls providing high mechanical strength and rigidity. An air cushion is formed between the layers, which also improves the NVH performance of a running engine. The block has 5 bolted main journals, which also provide high mechanical strength and rigidity to the lower part of the engine.

The cylinders are bored directly into the cylinder block, no cylinder liners are required. Two guide bushings are located on the cylinder block, they are provided for the correct alignment of the position of the cylinder head and gasket relative to the cylinder block.

The hole in the left rear of the cylinder block, under the starter, serves to install a special tool for adjusting the ignition timing. A special tool is inserted into the appropriate hole in the flywheel to temporarily hold the crankshaft in position with cylinder #1 at top dead center (TDC).

The oil filter and oil cooler housing and the main oil gallery are located on the left side of the cylinder block. The main oil gallery is bored longitudinally along the cylinder block and supplies pressurized oil to all moving parts of the engine. Pressurized oil is vented from the main oil gallery to feed the main and connecting rod bearings through diagonally drilled holes in the cylinder block and in the crankshaft journals. The main oil gallery is sealed at each end with threaded plugs.

A transverse bore drilled above the #2 main bearing directs pressurized oil from the main oil gallery to a port on the right side of the cylinder block. This port provides a pressurized oil supply through a nipple type "banjo" to VGT bearings. The oil returned from the VGT is fed through a pipeline and port on the right side of the block to the oil sump. A vertical passage drilled into the left front of the cylinder block supplies pressurized oil from the main oil gallery to the corresponding oil gallery in the cylinder head.

Engine cooling is provided by inter-cylinder coolant chambers and drilled expansion chambers provided in the cylinder block cooling jacket. Coolant chambers supply coolant through holes on the top surface of the block to the cylinder head. Rod plugs seal the external holes provided in the cooling jacket of the cylinder block.

Comments on this article