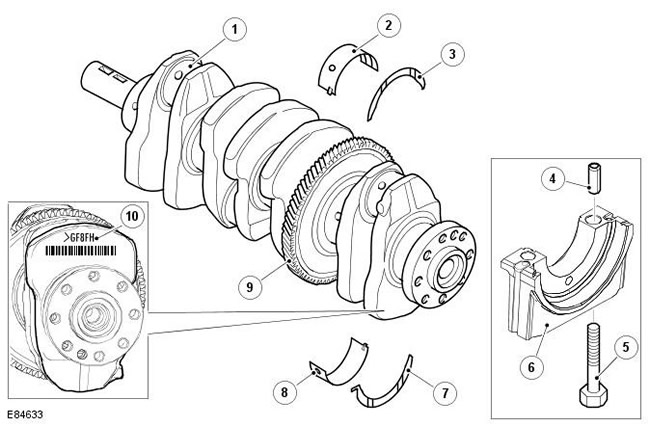

| Pos. | spare part no | Name |

| 1 | - | Crankshaft |

| 2 | - | Upper main bearing (4 things.) |

| 3 | - | Upper thrust washer (2 pcs.) |

| 4 | - | No. 1 Main Bearing Cap Locating Pin (2 pcs.) |

| 5 | - | Main bearing cap bolts (10 pieces.) |

| 6 | - | main bearing cap (5 pieces.) |

| 7 | - | Bottom thrust washer (2 pcs.) |

| 8 | - | Lower main bearing (4 things.) |

| 9 | - | Balance shaft drive gear |

| 10 | - | Classification marking of main bearings |

The crankshaft is made of steel and contains five journals of main bearings and four journals of connecting rod bearings. The main bearing journals are located in the main bearing housings of the cylinder block and are fixed by means of 5 main bearing caps. Each main bearing cap is stamped with the corresponding cylinder number for identification. The main bearing cap marked '1F' must be located on the transmission side of the engine (No. 1, on the edge).

The axial movement of the crankshaft is limited by four semi-circular thrust washers that are located on either side of the No. 2 main bearing. The thrust washers have oil grooves that must face the main bearing. The axial clearance of the crankshaft should be between 0.07 mm and 0.32 mm.

Each housing and main bearing cap has top and bottom bearings made of aluminium/tin. The top bearings have a bore and an annular groove to carry pressurized oil from the main bearing, through the crankshaft bores, to the connecting rod bearings.

The main bearing caps and upper and lower bearing shells are ribbed. The lugs ensure proper alignment of the bearing and cover and prevent radial movement of the bearing.

To maintain the required clearance of the crankshaft main bearing, main bearing shells of different thicknesses are provided. The upper main bearing shell is only available in one size, the lower main bearing shells are available in five sizes. Upper and lower main bearing shells are color coded for identification purposes. To select the correct size of the bearing shells, the classification markings on the front surface of the crankshaft and on the front surface of the cylinder block, as well as the bearing size table, are used.

For more information on installing main bearing shells, see the appropriate Maintenance and Repair Procedures Manual (SRP).

The drive gear is press-fitted onto the #3 crankshaft journal, which is located between the #2 main bearing journal and the #2 conrod bearing journal. This helical drive gear drives the balancer gears. At the front end of the crankshaft, behind the front crankshaft sealing plate, is an 18 tooth sprocket. The sprocket drives the oil pump assembly via a single row chain and is secured to the crankshaft with a segment key.

A toothed pulley mounted on the front end of the crankshaft drives the timing belt. The pulley has 21 teeth and is secured to the crankshaft by means of a key.

Comments on this article