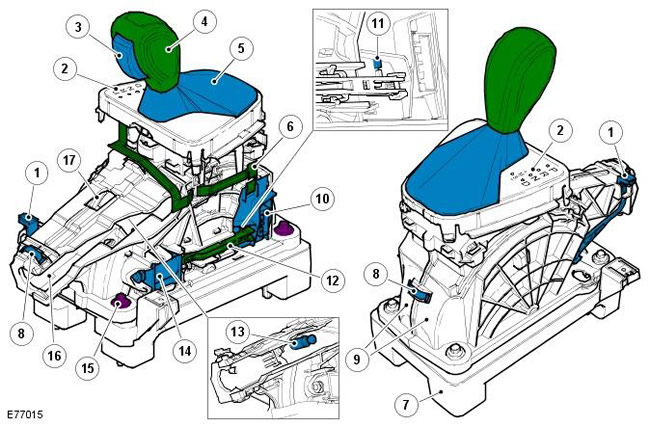

NOTE: Right hand drive vehicle shown

| Pos. | spare part no | Name |

| 1 | - | Lockout solenoid - Emergency release lever |

| 2 | - | LEDs (LED) selector position |

| 3 | - | Selector lever button |

| 4 | - | Lever |

| 5 | - | Case |

| 6 | - | Flat cable and PCB connector |

| 7 | - | Selector lever base plate |

| 8 | - | Spring clamp |

| 9 | - | Shift housing - left side and right side |

| 10 | - | Gear Shift Module |

| 11 | - | Mounting mark of the optical sensor |

| 12 | - | Sensor arm |

| 13 | - | Rope pin with spherical head |

| 14 | - | Shift lock solenoid |

| 15 | - | Bolt (4 things.) |

| 16 | - | Rope fastening hole |

| 17 | - | Rope Adjustment/Installation Opening |

The selector lever assembly is located centrally on the transmission tunnel, between the front driver and passenger seats, and is secured to the transmission tunnel with four bolts. The selector lever assembly is a maintenance-free electromechanical assembly used by the driver to select the desired transmission mode.

The driver's commands are transmitted from the selector lever via a cable to the transmission lever. The ball head pin connects to the lever mechanism and provides cable connection.

There are 5 positions of the selector lever and 2 additional positions for manual mode "CommandShift™":

- P (parking) - Prevents vehicle movement by locking the gearbox

- R (Reverse) - Selectable only when the vehicle is stationary and the engine is idling

- N (neutral position) - Torque is not transmitted to the drive wheels

- D (Movement) - All six forward gears are used in this position

- M/S (Sports mode) - In this position, all six forward gears are used in the same way as in the "D", but upshifting occurs at higher RPM to improve vehicle dynamics, and downshifting also occurs at higher RPM to improve engine braking.

- + / - (Manual CommandShift™) - Moving the selector lever in the + or - direction allows the driver to manually select a higher or lower gear from the six possible forward gears.

The position of the selector lever is displayed on the selector lever position LED display and on the instrument panel. In mode "CommandShift™", if the transmission is selected, but the TCM strategy (transmission control module) does not allow you to select this transfer, the requested transfer will be shown initially. The TCM will then shift into the nearest permitted gear and show it on the display.

Sensor module

The sensor module is located on the left side of the selector lever. The sensor module is an intelligent unit that controls the operation of the gear selector position LEDs and the operation of the shift lock solenoid. The sensor module includes a printed circuit board (PCB) and Hall sensors, which determine the selected position of the selector lever (M/S positions and + and -) using a magnet located in the lever mechanism. Signals from the Hall effect sensors are sent to the TCM from a connector on the sensor module via the LIN bus.

The sensor module's main connector provides 4 LIN bus pins for ground, power, and neutral input and output signals. The second connector is used to connect the flat cable from the selector lever position LED for night illumination and position indication illumination. The third connector is used to connect power and ground to the shift lock solenoid.

The sensor module also includes an optical sensor that detects when the selector lever is in the park position "R". The sensor is located behind the module body and is not visible. The alignment marks on the sensor body and the sensor lever must be aligned when the selector lever is in the parking position "R". If these two marks are aligned, then the position of the optical sensor/parking position is adjusted correctly. This adjustment is set at assembly and does not require resetting under normal operating conditions.

Sport Mode/Manual Mode +/- CommandShift™

The sensor module contains Hall sensors that are used to activate the sport/manual mode, as well as sensors that provide +/- signals. When the selector lever is moved to the position "manual/sport", the magnet located in the selector lever mechanism moves close to the M/S position Hall sensor located on the printed circuit board. In this case, a signal is generated that enters the TCM, which, in turn, turns on the sport mode.

When the selector is moved to the + or - position, the magnet approaches one of the Hall sensors located on both sides of the M/S position Hall sensor. When receiving a signal from a sensor "+" or "-" the manual CommandShift™ mode is activated. When the selector is released, the spring returns the selector lever to the center position. To exit CommandShift™ mode, move the selector to "D".

Shift lock

The shift lock solenoid is located on the left side of the selector lever. An electromagnet operates two lock levers that engage the lever mechanism and lock it in the parking position "P" or neutral "N" position. When the ignition is off, the electromagnet does not receive power, blocking the selector lever in the parking position "R". If the selector lever is in any position other than park "R", the remote control key cannot be removed from the launch control module until the lever is moved to the "R".

The shift lock solenoid is mechanically connected to the sensor module via the sensor arm. The movement of the electromagnet is transmitted via the sensor arm to the sensor module, which detects the movement by means of an optical sensor. Moving the sensor lever gives the sensor module confirmation that the solenoid is in the locked position. The sensor arm is adjusted by means of a ratchet mechanism. This adjustment is necessary to align the optical sensor and is set at the factory and does not require further adjustment.

The shift lock solenoid locks the selector lever in the park or neutral position to prevent accidental movement of the selector lever. The lock is released when the ignition is switched on and the brake pedal is pressed. The signal from the brake switch is transmitted via the high speed CAN bus to the TCM and then via the LIN bus to the sensor module. Upon receiving this signal, the sensor module, in accordance with its strategy, energizes the solenoid if the lever is in the parking position "R", or cuts off power to the solenoid if the lever is in the neutral position "N". This will unlock the mechanism.

If the selector lever remains in position "N" more than 3 seconds, the solenoid will be energized and the selector lever will be locked in position "N". In order to move the selector lever in this state from the position "N", you must press the brake pedal. This prevents unintentional movement of the selector lever to the position "D" or "R", and pressing the brake prevents "creeping" vehicle movement with the gear engaged. Even with the brake pedal depressed, the TCM prevents the selector from being moved from the "P" or "N", if the crankshaft speed exceeds 2500 rpm.

In the event of a fault in the shift lock solenoid, sensor module, brake switch, or related wiring, the emergency release lever can be used to release the lock mechanism. To access the emergency release lever, use a hand tool to remove the gear selector trim from the floor console. The trim must be lifted up to access the release lever, which is located at the front of the selector lever assembly and is painted yellow for quick retrieval.

NOTE: The selector lever cannot be moved from the park position "R", when the ignition is off, except when using the emergency release lever.

Comments on this article