NOTE: If the transmission is removed for access, the transmission fluid does not need to be drained because the transmission fluid cooler is not detached from the transmission assembly.

NOTE: If it is necessary to remove the transmission, it is not necessary to drain the transmission fluid unless the fluid cooler is disconnected from the transmission assembly.

Installation

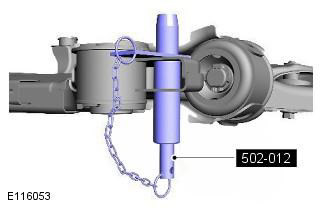

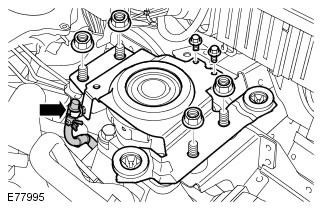

1. Remove the torque converter holder.

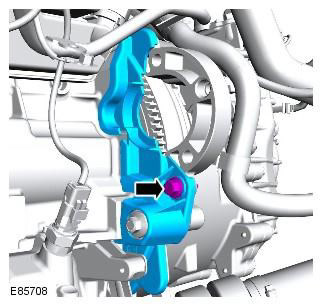

CAUTION: Make sure the pins are still in the engine and not in the gearbox.

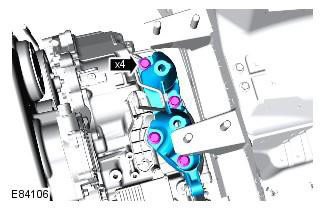

2. Install the gearbox and torque converter. Tightening torque: 47 Nm

Make sure that the torque converter remains in the gearbox. Correctly position the element on the dowel pins. Clean the mating surfaces and remove any rust or foreign material from them. Make sure the pins are on the engine and not on the gearbox.

NOTE: This step requires the assistance of a second mechanic.

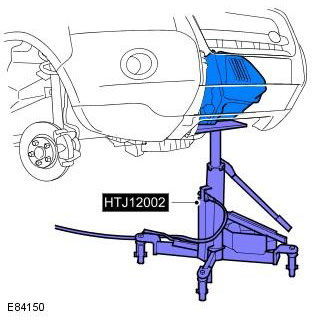

3. Remove the jack. General Equipment: Powertrain Jack

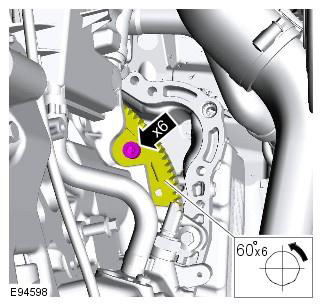

4. Fix the torque converter on the faceplate. Tightening torque: 60 Nm

CAUTION: Use new bolts.

5. Install the access cover.

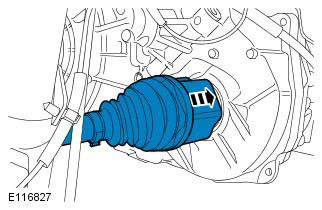

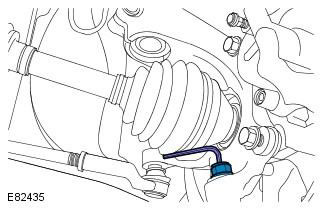

6. Establish the right half shaft. Tightening torque: PTO shaft support 25 Nm

7. Establish the left half shaft.

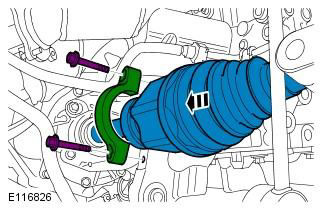

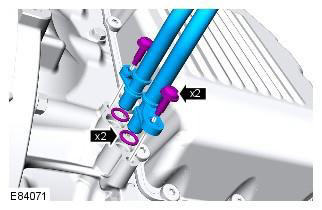

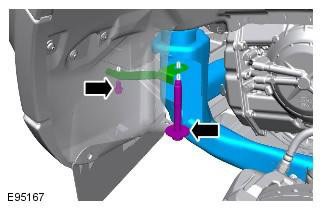

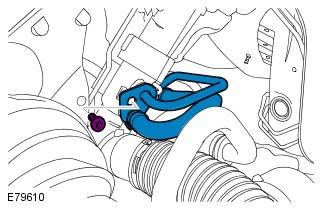

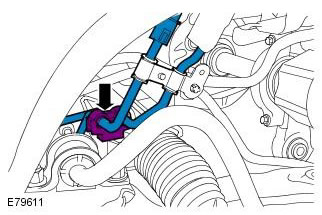

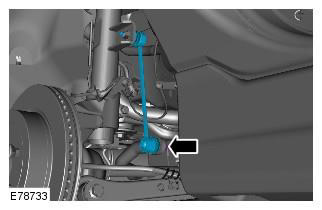

8. Connect transmission fluid cooler lines. Tightening torque: 10 Nm

Clean the area around the element and remove foreign matter from it. Install new o-rings.

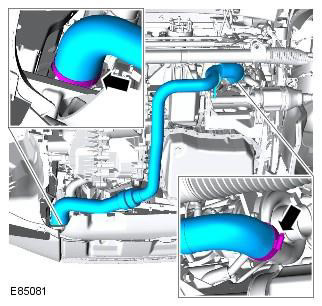

9. Install the turbocharger exhaust pipe.

10. Install the adjusting tool on the front subframe.

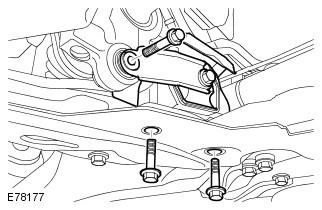

11. Install the front subframe. Tightening torque: Support bracket bolts 25 Nm. Subframe bolts - Stage 1: 140 Nm. Stage 2: 240°

CAUTION: Use only new subframe bolts.

NOTE: Install but do not fully tighten the front subframe mounting bolts.

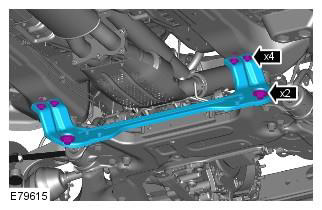

12. Install the subframe cross member. Tightening torque: Cross member bolts 45 Nm. Subframe bolts - Stage 1: 140 Nm. Stage 2: 240°

CAUTION: Use new bolts.

NOTE: Install but do not fully tighten the rear subframe mounting bolts.

13. Install the fuel line.

14. Fix catalytic converter of a distributive pipe.

15. Attach pressure lines of the steering mechanism. Tightening torque: 25 Nm

16. Fasten power steering lines.

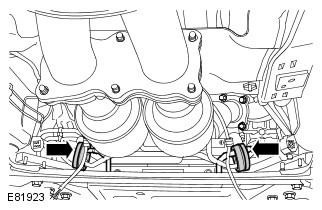

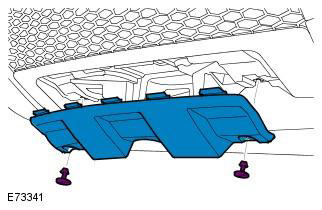

17. Install the bottom support pad. Tightening torque: 110 Nm

18. Install the ball joint of the lower suspension arm. Tightening torque: 110 Nm

WARNING: Install a new lower arm ball joint nut.

CAUTION: Do not allow the ball joint to rotate.

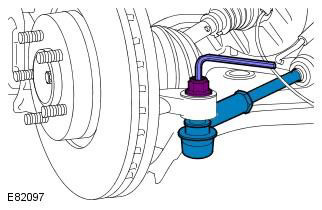

19. Connect the ball joints of the tie rod end. Tightening torque: 80 Nm

WARNING: Use new nuts.

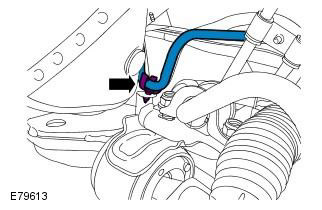

20. Attach both front struts to the stabilizer bar. Tightening torque: 55 Nm

WARNING: Use new nuts.

CAUTION: Do not allow the ball joint to rotate.

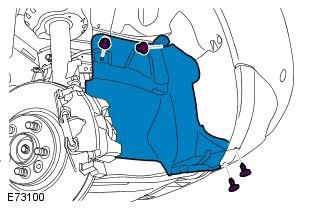

21. Install the left wing mudguard extension panel.

NOTE: The illustration shows the right side, on the left side the procedure is the same.

22. Install the front wheel and tire assembly. Refer to procedure: Wheel and tire (204-04 Wheels and tires, Removal and installation).

23. Install the towing device hole plug. Tightening torque: Bumper cover bolts 10 Nm

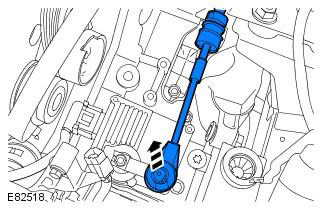

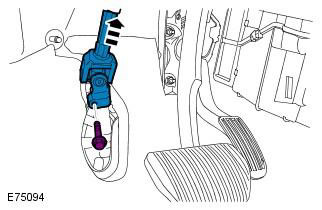

24. Fasten and connect the selector lever cable.

25. Install the engine support bracket. Tightening torque: 90 Nm

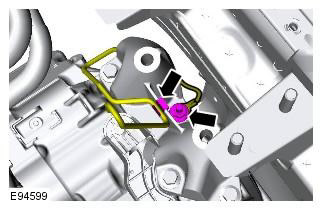

26. Install the ground strap. Tightening torque: 25 Nm

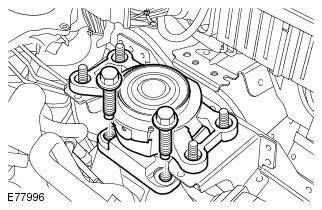

27. Install the left engine mount. Tightening torque: 175 Nm

28. Install bracket. Tightening torque: M12 80 Nm. M8 25 Nm

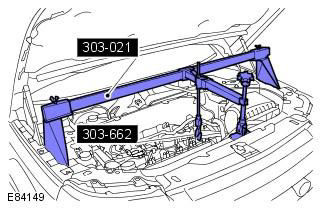

29. Remove prop from under the engine.

30. Install the starter. Refer to procedure: Starter (303-06B Starting system - 2.2L Duratorq - Td4, Removal and installation).

31. Install the battery tray. Refer to procedure: Battery installation shelf (414-01 Battery, battery mount and wires, Removal and installation).

32. Connect a steering column to the steering mechanism. Tightening torque: 25 Nm

WARNING: Install a new steering column flexible coupling bolt.

33. Fill the gearbox with transmission fluid. Refer to Procedure: Draining and Refilling Transmission Fluid - 2.2L Duratorq - Td4 (307-01 Automatic Transmission/Transaxle Transmission, General Procedures).

CAUTION: Before starting the engine, make sure there is enough power steering fluid in the reservoir. Failure to follow this instruction may result in damage to the vehicle.

34. Fill the power steering system with working fluid and remove air from the system. Refer to Procedure: Bleeding Power Steering System (211-00 Steering system - General information, General procedures).

35. If a new item is to be installed, configure using Land Rover approved diagnostic equipment.

Comments on this article