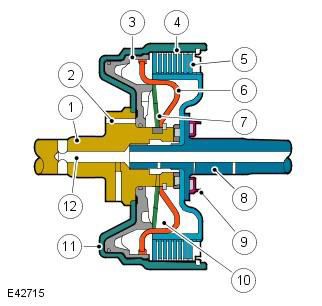

| Pos. | spare part no | Name |

| 1 | - | input shaft |

| 2 | - | Main pressure supply channel |

| 3 | - | Piston |

| 4 | - | Cylinder - outer thrust disc |

| 5 | - | Friction disc package |

| 6 | - | Partition |

| 7 | - | diaphragm spring |

| 8 | - | output shaft |

| 9 | - | Bearing |

| 10 | - | The balancing cavity of the centrifugal component of pressure |

| 11 | - | piston chamber |

| 12 | - | Lubrication channel |

The gearbox uses three drive and two brake clutches (B2 is a multi-disc brake clutch &B1 is a double brake band). Each clutch, depending on the output torque, contains one or more friction discs. A typical clutch consists of several steel outer discs and inner discs coated on both sides with friction material.

| Clutch / brake | Operating principle |

| Coupling C1 | Connects the front planetary carrier to the rear planetary rear sun gear |

| Clutch C2 | Connects the intermediate shaft to the carrier of the rear planetary gear |

| Clutch C3 | Connects the front planetary carrier to the rear planetary middle sun gear |

| Brake B1 | Blocks the middle sun gear of the rear planetary gear |

| Brake B2 | Blocks the carrier of the rear planetary gear |

The clutch discs are held in the separated position mechanically by a diaphragm spring and hydraulically dynamic pressure. The pressure is supplied through the lubrication channel, through which the fluid flows to the bearings, etc. The working fluid enters through the holes of the output shaft into the chamber between the baffle and the piston. To prevent inadvertent engagement of the clutch due to the centrifugal pressure component, a balancing chamber is provided which, in the absence of a static pressure component, keeps the piston in an equilibrium position.

When the clutch needs to be engaged, line pressure generated by a hydraulic pump is supplied to the chamber in front of the piston. Line pressure overcomes the low fluid pressure in the balance chamber. The piston moves against the pressure of the diaphragm spring and compresses the disc pack. When line pressure drops, the diaphragm spring pushes the piston away from the disc pack and the clutch disengages.

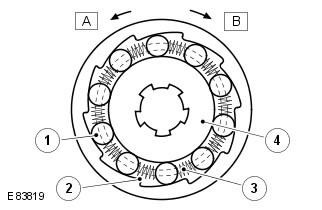

One way clutch

One way coupling - typical design:

| Pos. | spare part no | Name |

| 1 | - | Video clip |

| 2 | - | Frame (separator) |

| 3 | - | Spring |

| 4 | - | inner ring |

The roller clutch of a one-way clutch has 10 parallel rollers located between the smooth cylindrical inner ring and the beveled surfaces of the clutch housing. Springs are used to hold the rollers in place between the two contact surfaces.

When the clutch is rotated clockwise, the rollers are pinched between the inner race and the beveled surfaces of the clutch housing, forcing the inner race to rotate while blocking the counterclockwise rotation of the rear planetary carrier. When the clutch is rotated clockwise, the rollers move away from the beveled surfaces and can freely (not blocking) rotate with the clutch housing, transmitting power from the clutch to the rear planet carrier. In this state, the clutch rotates freely on the inner ring.

Comments on this article