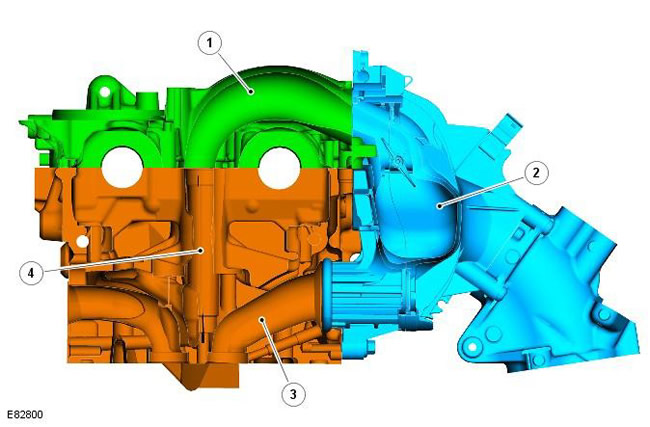

| Pos. | spare part no | Name |

| 1 | - | intake air path |

| 2 | - | Intake manifold |

| 3 | - | Swirl port head |

| 4 | - | Cylinder head filling port |

The cylinder head and intake manifold on the TD4 engine are designed to optimize swirl levels over the entire engine speed range and deliver a high volume of air to the cylinders. The intake manifold has a bottom row consisting of four helical swirl ports and an upper row consisting of four filling ports with a port cut-off device. These 8 ports are sealed against mating ports in the cylinder head and cylinder head cover with specially shaped O-rings. The helical swirl port is configured to create optimal swirl for efficient combustion; at the same time, the filling port is designed to supply large volumes of air without affecting the swirl in the cylinder. The intake manifold port cutoff device is controlled by the ECM. For more information see the chapter: Electronic Engine Controls - 2.2L Diesel (303-14 Electronic Engine Controls - 2.2L Diesel, Description and function).

Each cylinder receives air through the helical swirl port, and through the fill port when activated. The helical swirl port is always open and directs air from the lower intake manifold port into the combustion chamber. The fill port is normally closed and only opens under certain engine operating conditions when commanded by the ECM. The fill port, when open, directs air from the intake manifold's upper port through the curved intake tracts into the combustion chamber. The intake tracts are part of the cylinder head cover casting and connect the upper intake manifold fill ports to the machined cylinder head fill ports.

At low engine loads, gas flow is so low that the filling port closes. This causes an increase in the speed of the gases passing through the screw port and an increase in the swirl in the cylinder to the optimum intensity. To avoid the risk of high gas flow creating excessive swirl, the ECM opens the fill port during high gas flow conditions to maintain a constant optimum swirl throughout the engine's operating range.

Disabling intake manifold ports

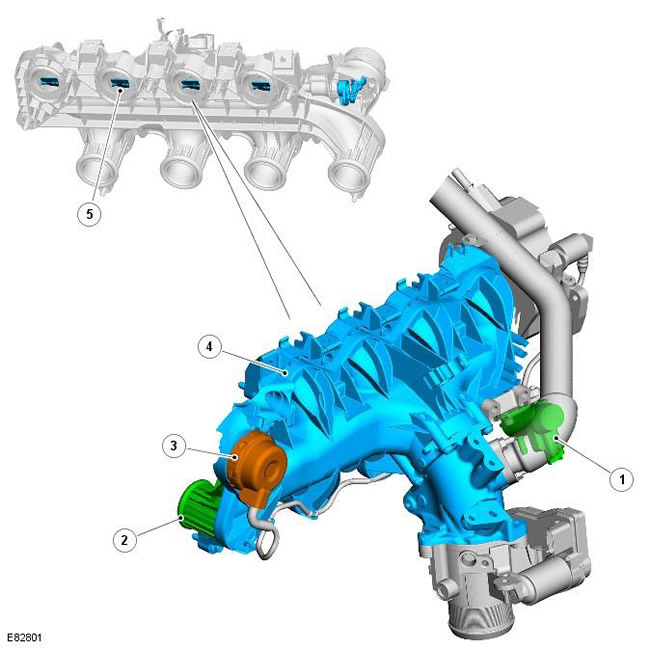

| Pos. | spare part no | Name |

| 1 | - | Solenoid valve |

| 2 | - | Screw swirl port intake manifold |

| 3 | - | vacuum actuator |

| 4 | - | Intake manifold filling port |

| 5 | - | Butterfly valve (4 things.) |

Port deactivation is performed by four butterfly valves mounted on a common shaft inside the intake manifold. Each butterfly valve is located in a corresponding top fill port on the intake manifold. The common shaft is connected to a vacuum actuator and actuated by a solenoid valve controlled by the ECM. The vacuum required to shut off the port is supplied by a vacuum pump mounted on the engine.

For more information, see chapter: Engine (303-01B Engine - 2.2L Duratorq - Td4, Description and function), Electronic Engine Controls - 2.2L Diesel (303-14 Electronic Engine Controls - 2.2L Diesel, Description and function).

Port disable (opening filling ports) only occurs when the coolant temperature is greater than 10°C and under the following conditions:

- The engine speed is above 1,800 rpm.

- Engine load is greater than 15%.

Comments on this article