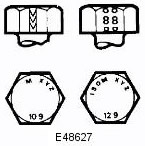

In addition to the manufacturer's designation, the bolt head also has a strength index designation, for example: 8.8; 10.9; 12.9; 14.9. Some bolts have the designation M and the strength index stamped on the edges of the hexagon.

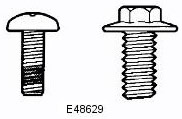

Bolts protected with anaerobic sealant (encapsulated)

Self-locking bolts

Bolts and screws with a nylon insert are coated with or inserted into the threaded part of the sealant. These bolts can be identified by a colored insert that extends half the length of the bolt's shank, or by a colored plug inserted into the bolt.

Another type of self-locking bolts are bolts with threads that slightly mismatch the threads of the mating hole or nut into which the bolt is threaded.

CAUTION: DO NOT reuse self-locking bolts to assemble critical connections (engine bearings, flywheel bolts). Do not install conventional fasteners in place of the designed self-locking nuts, bolts or screws.

Type 2 self-locking bolts must not be used instead of bolts protected with anaerobic sealant (encapsulated).

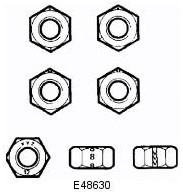

Nut designation

Instead of indicating the strength index, the so-called "hourly" method of specifying the strength index. A mark is applied to the outer chamfer or end of the nut, which corresponds to the readings of the clock hands. Indications "hours" and are the designation of the strength index.

A dot is used to indicate the 12 o'clock mark, and (strength index values) notch is used. If the strength index is greater than 12, then a double dot is used to indicate the 12 o'clock mark.

When tightening "crown" nut with cotter pin slots, never loosen the nut to align the cotter pin holes. An exception is the case when this is provided for by the adjustment instruction. If you can't align the cotter pin holes, try replacing the washer or nut.

If the nut is used to control bearing preload, the nut must be tightened according to the tightening procedure.

Self-locking nuts

Comments on this article