CAUTION: Special tools have been developed for dismounting most types of bearings; they should be used whenever indicated.

To ensure the long life of the units when removing and installing bearings, follow the guidelines listed below:

- All traces of grease must be removed. For washing, use special formulations. During assembly/disassembly operations, keep the work area absolutely clean.

- Carefully inspect the rolling elements, treadmills, the outer cylindrical surface of the outer ring and the inner cylindrical surface of the inner ring. Bearings must be replaced if traces of friction are found in the indicated areas, as this indicates wear.

- Pinch the inner race of the bearing between the index and thumb fingers of one hand. Rotate the outer race with your other hand. Rotation should not be accompanied by sticking and extraneous sounds. Now clamp the outer race and rotate the inner one. DO NOT spin the bearing too fast.

- While holding the inner ring, gently rotate the outer ring in a reciprocating motion to ensure that rotation is not obstructed. The bearing must be replaced if the rotation of the ring is not smooth enough.

- Check the bearing for signs of burnishing or overheating.

- Lubricate the bearing with a recommended lubricant.

- Inspect the shaft journal and seat in the housing. Discoloration or other marks indicate a loose bearing fit.

- Before mounting the bearing, clean the shaft journal and the bore of the housing for the bearing from dirt and burrs.

- If one of the bearings in a pair shows signs of wear, overheating, etc., it is recommended that both bearings be replaced. The exception is when it is suspected that one of the bearings was defective during installation, was installed incorrectly, or that the failure was caused by a seal failure.

- Never reinstall a bearing without first verifying its full suitability.

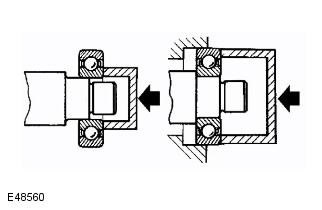

When mounting the bearing on the shaft, apply force to the inner ring. When mounting the bearing into the housing bore, apply force to the outer ring.

CAUTION: Special tools have been developed for dismounting most types of bearings; they should be used whenever indicated.

If the bearings are grease lubricated, fill the space between the bearing and the outer seal with the recommended grade of grease before mounting the seal.

CAUTION: When using a waxed gland (dry fit) be especially careful not to contaminate the running surface of the seal with grease.

Disassembled bearing parts (e.g. tapered bearings) always mark when disassembling so as not to confuse when reassembling. Do not attempt to replace rollers without changing the outer race. The entire bearing must be replaced.

Comments on this article