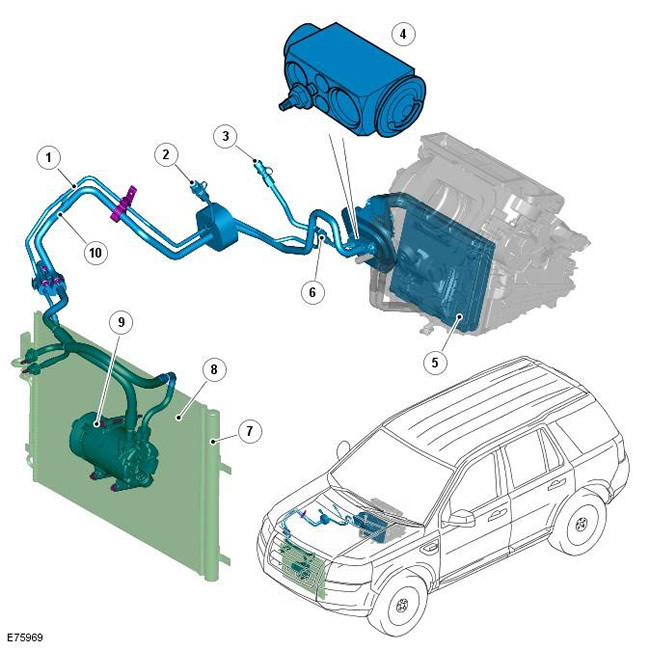

| Pos. | spare part no | Name |

| 1 | - | High pressure line |

| 2 | - | High pressure service port |

| 3 | - | Low pressure service port |

| 4 | - | expansion valve |

| 5 | - | Evaporator |

| 6 | - | Refrigerant pressure sensor |

| 7 | - | Receiver dryer |

| 8 | - | Capacitor |

| 9 | - | Air conditioning compressor (A/C) |

| 10 | - | Low pressure line |

The A/C system transfers heat from the passenger compartment to the outside air to provide the heater with dehumidified cold air.

The A/C system is a hermetic closed system which is charged with R134a refrigerant as a heat transfer medium. Refrigerant charge weight for i6 and TD4 vehicles is 730 g. Oil is added to the refrigerant to lubricate the internal components of the A/C compressor.

Although the A/C compressors found on i6 gasoline engines and TD4 diesel engines are different, they are both variable displacement units. Feed control (refrigerant consumption) is carried out to match the heat load of the evaporator.

The A/C system is controlled by an automatic temperature control module (ATC). For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

Air conditioning compressor

NOTE: A/C compressor shown for i6 engine, similar for TD4

The A/C compressor is driven by the engine accessory drive belt. It pumps the refrigerant through the system by compressing the vapor coming from the evaporator at low pressure and low temperature and sending the compressed vapor at high temperature and high pressure to the condenser.

A relief valve is installed on the outlet side of the A/C compressor to prevent overpressure in the system. The safety valve relieves excess pressure in the engine compartment.

i6

I6 vehicles are equipped with a Zexel-Valeo KC-88 Variable Delivery A/C Compressor. Compressor flow controlled by the engine control module (ECM), based on the current evaporator temperature and evaporator set temperature signals received from the ATC module. Based on these values, the ECM calculates the required compressor flow and applies a pulse-width modulated signal to the compressor solenoid valve. The compressor solenoid valve is mounted on the rear side of the compressor and interprets the PWM signal as a flow value and changes the position of the internal swash plate accordingly. For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

The ECM also reduces the A/C compressor flow to match its minimum level if a full throttle or function is requested "kick down" in an automatic transmission. This feature is not available on vehicles destined for the Gulf countries.

Compressor clutch engagement is controlled by the ECM. For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

TD4

TD4 vehicles are equipped with a Visteon VS16 variable displacement A/C compressor. The flow is controlled by a control valve built into the compressor. The control valve senses the refrigerant pressure at the compressor inlet and outlet and adjusts the angle of the internal swash plate accordingly.

NOTE: A/C compressor swashplate angle is not externally controlled. Therefore, compressor flow is not controlled or calculated by any external control.

Compressor clutch engagement is controlled by the ECM. For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

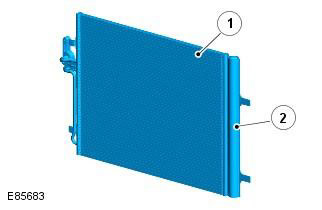

Capacitor

| Pos. | spare part no | Name |

| 1 | - | Capacitor |

| 2 | - | Receiver dryer |

The condenser is designed to convert refrigerant vapor from the high-pressure gaseous phase obtained in the compressor into liquid and to remove heat from the refrigerant to the environment. The condenser is installed directly in front of the radiator of the cooling system. Two brackets located on the tanks serve to attach the condenser to the radiator tanks.

The condenser, the main elements of which are two tanks and a finned tube heat exchanger located between them, belongs to the class of post-cooling condensers. Baffles in the tanks divide the condenser into four ascending sections (condensing) and two descending sections (additional cooling).

The right tank has ports for connecting the high pressure line from the A/C compressor and the low pressure line to the evaporator.

Receiver dryer

The receiver-drier is built into the left condenser tank, it removes solids and moisture from the refrigerant. It also works as a liquid refrigerant storage tank to compensate for the effects of changing heat load in the evaporator.

The refrigerant enters the receiver-drier, passes through a filter and a desiccant, then collects at the bottom of the receiver-drier and returns to the condenser through the outlet pipeline.

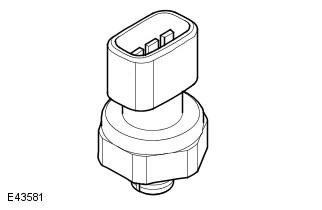

Refrigerant pressure sensor

The refrigerant pressure sensor provides the ATC module with a pressure input signal from the high pressure side of the refrigerant system. The refrigerant pressure sensor is permanently wired to the ECM, which uses the signal to control the operation of the A/C compressor and to calculate the additional engine load that the A/C compressor will generate. In addition, the ECM transmits a high refrigerant pressure signal via the CAN bus to the central electrical junction box (CJB). The CJB sends a signal on the medium speed CAN bus to the ATC module to increase the amount of recirculated air, if necessary.

The refrigerant pressure sensor is located in the line between the condenser and expansion valve. For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

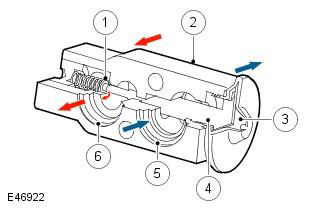

Expansion valve

| Pos. | spare part no | Name |

| 1 | - | Dosing valve |

| 2 | - | Frame |

| 3 | - | Diaphragm |

| 4 | - | temperature sensor |

| 5 | - | Evaporator outlet |

| 6 | - | Evaporator inlet |

The expansion valve is designed to regulate the amount of refrigerant entering the evaporator in accordance with the heat load from the air passing through the evaporator.

The block type expansion valve is located downstream of the heater and connected to the inlet and outlet ports of the evaporator. The aluminum housing of the expansion valve contains the inlet and outlet ports. A metering valve with a spring-loaded ball is installed in the inlet channel, and a temperature sensor is located in the outlet channel. The role of the temperature sensor is played by a thermal bulb connected to the cavity above the membrane. The lower part of the bulb acts on the dosing valve ball. The pressure above the membrane depends on the temperature at the outlet of the evaporator, which is transmitted through the capillary tube of the bulb. The lower part of the membrane takes up the pressure at the outlet of the evaporator.

The liquid refrigerant flows through the metering valve to the evaporator. The restriction in the metering valve reduces the pressure and temperature of the refrigerant. This constriction also converts the liquid refrigerant stream into a thin jet, which improves the evaporation process. Passing through the evaporator, the refrigerant absorbs heat from the air passed through the evaporator. When heated, the refrigerant evaporates and its pressure increases.

The temperature and pressure of the refrigerant leaving the evaporator act on the bulb and on the membrane, which regulate the flow area of the metering valve and, accordingly, the amount of refrigerant passing through the evaporator. The warmer the air around the evaporator, the more refrigerant evaporates and the more refrigerant passes through the metering valve.

Evaporator

The evaporator is installed in the heater between the blower fan and the heater core and absorbs heat from the air supplied either from outside (supply mode), or from the salon (recirculation mode). In the evaporator, the cold liquid refrigerant under low pressure turns into vapor, absorbing a large amount of heat in the process of changing the state of aggregation.

Most of the moisture contained in the air that passes through the evaporator condenses and drains out of the heater through a drain pipe under the bottom of the vehicle.

Refrigerant lines

The diameter of the refrigerant lines in different parts of the air conditioning circuit varies to maintain equal refrigerant flow rates in accordance with the two pressure and temperature regimes. Refrigerant with low pressure and temperature passes through large diameter lines, and heated refrigerant with high pressure passes through pipelines with a smaller diameter.

The low pressure line to the A/C compressor and the high pressure line from the condenser use low permeability nylon lined rubber hoses. The rest of the refrigerant lines are made of steel.

Low and high pressure ports are provided in the refrigerant lines for servicing the system.

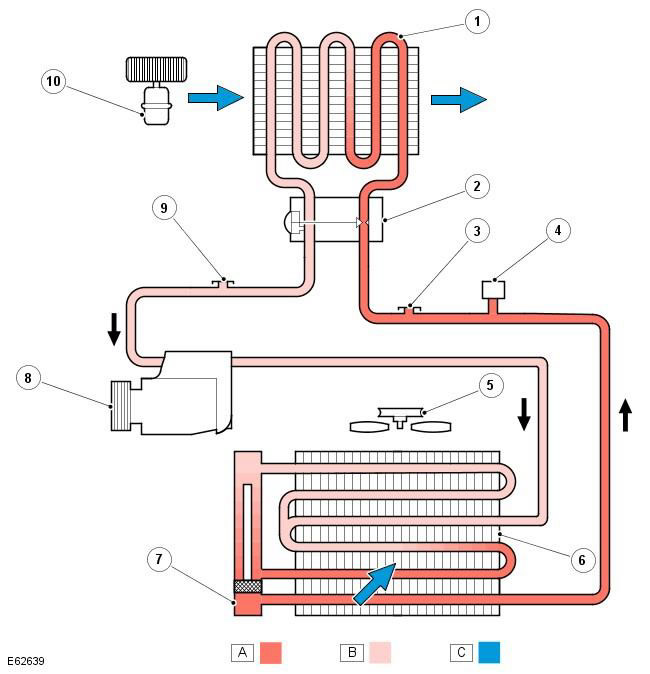

Control scheme

NOTE: A = Liquid refrigerant; B = Refrigerant vapor; C = Airflow

| Pos. | spare part no | Name |

| 1 | - | Evaporator |

| 2 | - | expansion valve |

| 3 | - | High pressure service port |

| 4 | - | Refrigerant pressure sensor |

| 5 | - | Engine cooling fan |

| 6 | - | Capacitor |

| 7 | - | Receiver dryer |

| 8 | - | A/C compressor |

| 9 | - | Low pressure service port |

| 10 | - | Cooling Fan |

To achieve the effect of heat transfer, forced circulation of the refrigerant is carried out, which undergoes a change in the state of aggregation twice. In the process of each change in the state of aggregation, the greatest absorption or release of heat occurs.

Low pressure/low temperature side - from the expansion valve, through the evaporator to the compressor. The pressure and temperature of the refrigerant decreases in the expansion valve, and then in the evaporator the refrigerant changes its state of aggregation, passing from liquid to vapor, which is accompanied by heat absorption.

High pressure/high temperature side - from the compressor, through the condenser and receiver-drier to the thermostatic expansion valve. The pressure and temperature of the refrigerant increase as it passes through the compressor, then heat is released and the refrigerant changes from vapor to liquid in the condenser.

The A/C system is controlled by an automatic temperature control module (ATC). For more information, see the chapter: Control Components (412-01 Climate control, Description and principle of operation).

Comments on this article