When the request to turn on the heating is deleted or if the outdoor temperature rises to 8°C, the ATC module sends a message "heater off." to the FFBH control module via the medium speed CAN bus. The control module responds by returning a message to the ATC module "heater off.". The control module now disables FFBH.

If maximum heating is requested, the coolant temperature (ECT) becomes the determining factor. In this case, the ATC module changes the message transmitted over the CAN bus from "heater off." on "additional heating", when the engine coolant temperature is 70°C or lower. If the engine coolant temperature rises to 78°C, the ATC module returns a message "heater off.".

The controller will not turn on the flare heater or will interrupt its operation if one of the following conditions exists:

- Control module blocked due to a fault (see Diagnostics section below).

- The engine does not run or stops for more than 4 seconds. A turn-on delay period is provided to detect engine stop.

- Message received from CJB on medium speed CAN bus "fuel cut off". For more information, see chapter: Airbag and Pretensioner Restraint System (SRS) (501-20B Secondary Restraint System Description and Operation).

- Low Fuel Message Received from CJB on Medium Speed CAN Bus (see table below). For more information, see chapter: Instrument panel (413-01 Instrument panel, Description and function).

The control module controls the operation of the FFBH based on the following levels of fuel in the tank:

| Fuel level, liters (US gallons) | Description |

| 7,5 (1,98) | Beginning of work |

| 4,5 (1,18) | Termination of work |

| 10,5 (2,77) | Restart |

Start sequence

At the start of the start sequence, the FFBH control module:

- supplies power to the glow plug and flame sensor to preheat the combustion chamber

- starts at low speed the fan for supplying air to the combustion chamber

- and supplies power to the auxiliary coolant pump

After approximately 30 seconds, the control module powers up the auxiliary fuel pump in heater start mode. In the combustion chamber, the fuel from the auxiliary fuel pump is vaporized, mixed with the air supplied by the fan, and ignited by a flame-sensing glow plug. The control module then gradually increases the capacity of the auxiliary fuel pump and combustion air blower. After stabilization of the combustion process in the combustion chamber, the control module switches the glow plug with flame sensor to flame sensor mode to monitor the combustion process. From the moment of ignition to stable combustion at full heat load, approximately 150 seconds pass.

Full and partial load

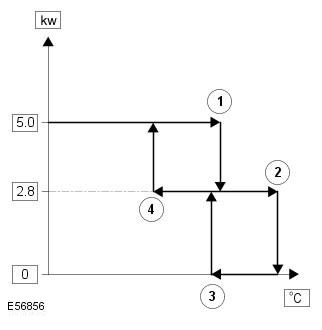

When the FFBH is operating, the control module selects full thermal load, partial load, and idle operation of the fuel-fired auxiliary heater based on the heat exchanger coolant temperature.

The heat output level at partial load is 2.8 kW. At full load, it rises to 5 kW. The control module reports the amount of fuel used to the instrument panel and the coolant temperature in the FFBH module to the ATC module.

Switching temperatures

| Switching point | ||

| Item number | Description | Temperature, ºC (ºF) |

| 1 | From full load to partial | 79ºC (174ºF) |

| 2 | From partial load to idle | 90ºC (194ºF) |

| 3 | From idle to partial load | 74ºC (165ºF) |

| 4 | From partial load to full load | 69ºC (156ºF) |

After the startup sequence is complete, the control module maintains full load until the coolant temperature reaches switchpoint 1. At this temperature, the control module enters partial load mode, roughly halving the output of the auxiliary fuel pump and combustion air blower. Part load mode is maintained as long as the coolant temperature stays between switchpoints 2 and 4. In part load mode, the coolant temperature can both rise and fall, depending on the amount of heat needed to heat the passenger compartment. If the coolant temperature drops to switchpoint 4, the control module increases the pump and combustion air blower output, returning to full load. If the coolant temperature rises to switch point 2, the control module switches to idle mode.

When idle is engaged, the control module immediately turns off the auxiliary fuel pump to stop combustion and starts the combustion air blower timer. After two minutes of cooling, the control module turns off the combustion air blower and then maintains idle operation as long as the temperature in the heat exchanger housing remains above switch point 3. When the coolant temperature drops to switch point 3, the control module places the system in partial load mode. It takes approximately 90 seconds from start to partial load.

To limit fouling on the flame sensing glow plug, the control module will also go into idle mode if continuous operation exceeds 72 minutes (full load, part load or a combination of both). If the coolant still requires additional heating after the cooling period has elapsed, the control module restarts the fuel-fired auxiliary heater.

Shutdown

To turn off the FFBH, the control module stops burning by turning off the auxiliary fuel pump, but leaves the combustion air blower running for a while to cool the fuel-fired auxiliary heater. The cooling time is 100 seconds when stopping from part load and 175 seconds from full load.

Diagnostics

The control module monitors the fuel-fired auxiliary heater and logs faults. Diagnostic Trouble Codes (DTC) stored in the control module's volatile memory and can be read from the Land Rover approved diagnostic system via the medium speed CAN bus.

The control module is also equipped with a fault lockout function that, when a fault is detected, stops the system from operating, preventing it from being damaged. In Fault Lockout mode, the control module immediately turns off the auxiliary fuel pump, and after about 2 minutes, turns off the combustion air blower and the additional coolant pump. Fault blocking occurs in the following cases:

- Violation of the starting procedure and termination of the combustion process: If stable combustion cannot be achieved at start or the flame disappears after the combustion process has stabilized, the control module will initiate a restart. Failed start or loss of flame is recorded by an event counter in the control module. The event counter is incremented by one for each failed start or flame failure, and decremented by one for each subsequent successful start. If the event counter increases to three (for any number of start cycles), the control module enters the fault lockout mode.

- Overheating of the heat exchanger housing: To protect the system from overheating, the control module enters a fault lockout mode if the coolant temperature at the heat exchanger outlet exceeds 125°C.

- Battery voltage out of range: Fault lockout will occur if the battery voltage falls below 10.25V and rises above 15.5V.

Fault information can be cleared from the control module memory using a Land Rover approved diagnostic system or by disconnecting the battery for at least 10 seconds.

Remote control operation

The 868.3 MHz radio signals transmitted by the remote control are received by the DAB/FFBH antenna located in the left rear window. The signals received by the antenna are decoded by the FFBH receiver. An acknowledgment signal is sent back from the receiver to the remote to confirm the validity of the turn on or off request in order to activate the remote's indicator light accordingly. The receiver processes the signal it has received and transmits the corresponding signals to the FFBH control module via a special bus.

NOTE: The acknowledgment signal only confirms that the communication between the console and the receiver was successful, and does not confirm the activation of the FFBH.

When the FFBH is activated by the remote control, the control module allows the FFBH to operate for 30 minutes or until a shutdown request is received from the remote or CJB. During the 30 minute period, the FFBH can operate in full thermal load, partial load or idle mode, depending on the temperature of the coolant in the heat exchanger.

Threshold values for pre-combustion

The FFBH will be activated remotely when the following conditions are met:

- Pre-combustion battery voltage test: ≥11.5V (voltage at FFBH terminals)

- Pre-combustion coolant temperature test: ≤15°C (internal measurement FFBH)

- Pre-combustion fuel level check: ≥7.5L (value stored in FFBH when ignition is off)

The fuel level value stored in the FFBH block is updated only when the engine is running. When the FFBH is started by remote control with the engine off, the fuel level value used in the FFBH calculations will be the value stored the last time the ignition was turned off. It is therefore possible that the FFBH will not be able to operate with remote control if the engine has been shut down with low fuel; if the fuel tank is then refueled, the fuel level stored in FFBH will still read low if the engine has not been started after refuelling.

If the FFBH does not activate due to low battery voltage or low fuel, its control module sends a message across the medium and high speed CAN buses through the CJB to the instrument cluster message center, which will display one of the following messages when the ignition is on:

- AUXILIARY HEATER UNAVAILABLE LOW FUEL (AUXILIARY HEATER NOT AVAILABLE - LOW FUEL)

- AUXILIARY HEATER UNAVAILABLE LOW BATTERY (AUXILIARY HEATER NOT AVAILABLE - LOW BATTERY)

If both messages are valid (for low fuel and low battery), the message center on the instrument panel will alternate between displaying the two messages.

Transitions from 'Park Heat' mode (Parking heating) remote control to 'Supplementary Heat' mode (Additional heating) ATC

NOTE: FFBH can still be activated by the ATC module as described above

If FFBH was running in remote mode („park heat‟) and the vehicle is started while FFBH is still active, a transition to ATC control mode "supplementary heat‟ will be performed if the ATC requests it.

If the ATC then sends a message to the FFBH to turn off, the FFBH will remain active unless 30 minutes have elapsed from the original 'park heat' request via the remote control system. After the remaining time of 30 minutes has elapsed, the FFBH will turn off.

Switching temperatures

With remote start, the FFBH uses a different set of switching temperatures for normal 'supplemental heat' operation. The reason is that the remote start function can start the FFBH when the engine is off - so other thresholds are required to optimize engine coolant heating.

Switching temperatures:

| Switching point | ||

| item number | Name | Temperature, ºC (ºF) |

| 1 | From full load to partial | 80ºC (176ºF) |

| 2 | From partial load to idle | 90ºC (194ºF) |

| 3 | From idle to partial load | 50ºC (122ºF) |

| 4 | From partial load to full load | 70ºC (158ºF) |

Comments on this article