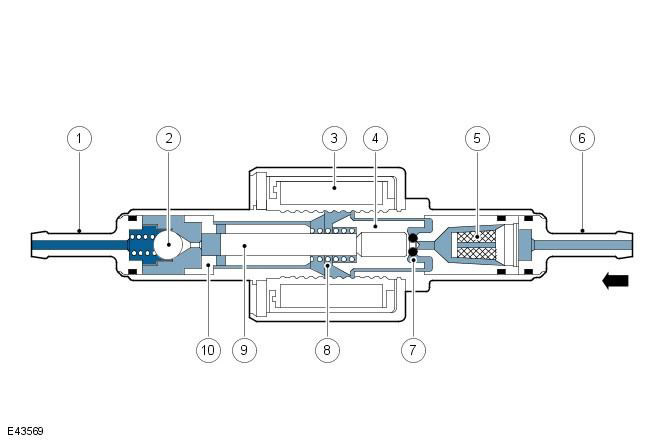

| Pos. | spare part no | Name |

| 1 | - | fuel line fitting |

| 2 | - | check valve |

| 3 | - | Electromagnet winding |

| 4 | - | Plunger |

| 5 | - | filter element |

| 6 | - | fuel line fitting |

| 7 | - | Sealing ring |

| 8 | - | Spring |

| 9 | - | Piston |

| 10 | - | Sleeve |

The auxiliary fuel pump is located on the right side of the fuel tank and regulates the fuel supply to the fuel-fired auxiliary heater. The solenoid driven self-priming pump is pulse width modulated from the control module in the FFBH. In the event of a blackout, the pump forcibly cuts off the fuel supply to the auxiliary heater module.

The winding of the electromagnet of the additional fuel pump is installed on the housing, in which the plunger and piston are located. The piston is located in the sleeve, which is acted upon by a spring resting with its other end against the plunger. At the entrance to the housing there is a fitting for connecting the fuel line and a replaceable fuel filter. At the outlet of the housing there is a fitting for connecting the fuel line and a check valve.

When the solenoid winding is de-energized, the spring holds the piston and plunger in position, blocking the access of fuel to the pump housing. The sealing ring ensures the tightness of the plunger and prevents the flow of fuel from the filter through the pump. When the winding is energized, the piston and plunger move forward towards the outlet end of the pump housing until the piston comes into contact with the sleeve. In this case, the fuel enters the pump through the inlet connecting fitting and filter. As a result of the initial displacement of the piston, the transverse holes in the sleeve are also closed, and the discharge cavity at the outlet end of the pump housing is isolated. Further advancement of the piston forces the fuel out of the pressure chamber through the check valve into the pipeline leading to the fuel-fired auxiliary heater. After de-energizing the electromagnet winding, the spring returns the piston and plunger back to the position that closes the pump. As the piston and plunger retract to the closed position, the fuel, bypassing the plunger through the annular gaps and transverse holes in the sleeve, again fills the discharge cavity.

Comments on this article