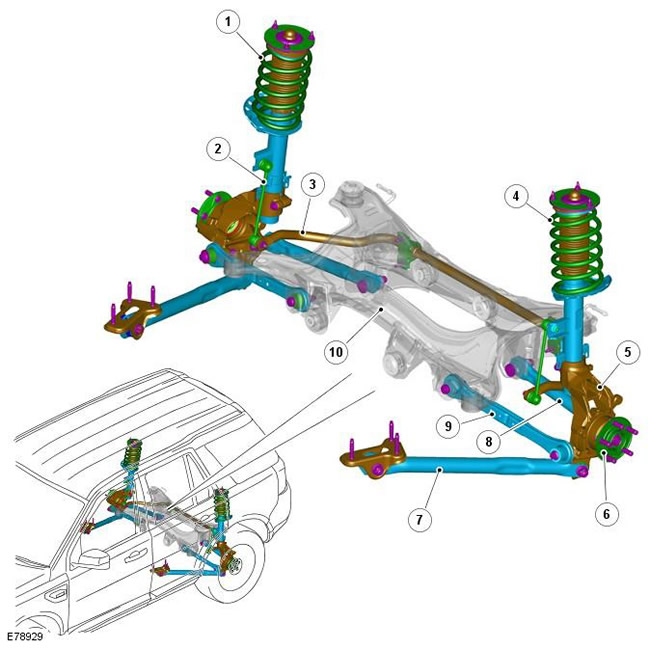

Location of elements

| Pos. | spare part no | Name |

| 1 | - | Right (RH) spring and damper assembly |

| 2 | - | Front stabilizer |

| 3 | - | The bar of the stabilizer bar |

| 4 | - | Left (LH) spring and damper assembly |

| 5 | - | wheel fist |

| 6 | - | Hub |

| 7 | - | Longitudinal tie rod |

| 8 | - | Rear tie rod |

| 9 | - | Front tie rod |

| 10 | - | Stretcher |

Review

The rear suspension uses long-travel MacPherson struts to optimize on-road and off-road performance.

The suspension elements are mounted on a subframe, which forms a rigid platform attached to the bottom of the car body. The subframe is mounted on the body on four bushings with non-constant compression ratios to absorb lateral and longitudinal loads when cornering and braking.

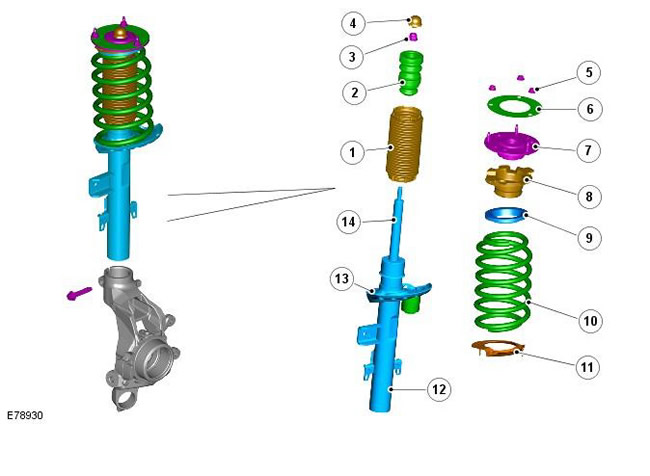

Spring and damper

| Pos. | spare part no | Name |

| 1 | - | Rubber cuff |

| 2 | - | Auxiliary device elastic element |

| 3 | - | Lock-nut |

| 4 | - | Lid |

| 5 | - | Locknut (3 pcs.) |

| 6 | - | Pad |

| 7 | - | Upper support assembly |

| 8 | - | remote element |

| 9 | - | Spring insulator |

| 10 | - | Spring |

| 11 | - | Spring insulator |

| 12 | - | shock absorber housing |

| 13 | - | Spring seat |

| 14 | - | shock absorber piston rod |

The spring and damper assembly is a twin-tube design, the traditional coil spring sits on a welded spring seat on the damper tube. The lower end of the shock absorber housing is located in the wheel knuckle, which is secured with a bolt.

The damping capacity of the shock absorber is determined by the limitation of the flow of the working fluid through the internal channels of the shock absorber. The shock absorber rod moves along the axis of the working cylinder, and due to the resistance to fluid flow, forces are created that prevent the relative movement of the rod and the working cylinder. These forces cause the damping of vibrations that occur when the car moves over road bumps. A seal is installed between the shock absorber rod and the working cylinder, which, on the one hand, does not allow the working fluid to leak out, and on the other hand, prevents dirt and moisture from penetrating into the shock absorber. In addition, the seal acts as a rod cleaner.

The damper rod passes through the center hole of the upper mount assembly. The outer end of the stem is threaded. A self-locking nut secures the shock absorber rod to the upper support. The auxiliary device of the elastic element is installed on the shock absorber rod. It prevents the upper mount from contacting the top of the shock when the suspension is fully compressed, and also helps to tune the suspension. A rubber cuff is installed between the shock absorber body and the upper support; it protects the shock absorber piston rod from damage.

The spring to be installed depends on the specification of the vehicle. Each spring is color coded for rating and installation conditions.

The spring is located in the spring seat, which is an integral part of the shock absorber body and includes the spring isolator. The design of the spring seat prevents the spring from rotating. The spring has a linear compression ratio and is inclined to counteract the forces acting in turns. The opposite end of the spring is also in the spring insulator which is installed in the top support assembly. Both spring insulators are made of rubber and prevent the noise generated by the expansion / compression of the shock absorber and spring from being transmitted to the car body. A shock-absorbing weight is attached to the shock absorber spring seat, designed to absorb vibrations and prevent noise from entering the vehicle interior.

The top support has a gasket that prevents moisture from penetrating between the support and the mount. The top support is attached to the hardened rack dome on the chassis with 3 built-in studs and self-locking nuts.

Two brackets are welded to the shock absorber body. One bracket secures the stabilizer bar. The second bracket secures the brake hose and wheel speed sensor wire. This bracket also positively locks the damper into the wheel knuckle and its position is critical to controlling the trim height of the vehicle body.

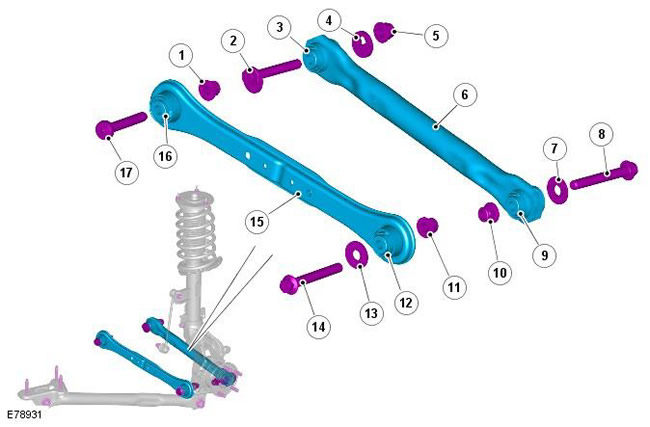

Tie rods

| Pos. | spare part no | Name |

| 1 | - | Lock-nut |

| 2 | - | eccentric bolt |

| 3 | - | Inner sleeve |

| 4 | - | Eccentric Cam Washer |

| 5 | - | Lock-nut |

| 6 | - | Rear tie rod |

| 7 | - | Washer |

| 8 | - | Bolt |

| 9 | - | Outer sleeve |

| 10 | - | Lock-nut |

| 11 | - | Lock-nut |

| 12 | - | Outer sleeve |

| 13 | - | Washer |

| 14 | - | Bolt |

| 15 | - | Front tie rod |

| 16 | - | Inner sleeve |

| 17 | - | Bolt |

The lateral position of the wheel is controlled by 2 tie rods located between the subframe and the wheel knuckle. The links are made long for perfect camber control. Each tie rod is equipped with dynamic bushings that control rear camber, progressively changing camber as cornering load increases, resulting in limited passive rear wheel steer. The 2 tie rods are of different design. The front link is made of stamped steel. The rear link is made from a pressed and cut pipe. The tie rods are designed to withstand the vehicle's lifting loads.

The front tie rod is equipped with bushings that compress under cornering forces which, in addition to camber control, provides controlled rear wheel toe-in. There is a deformation point in the middle of the front link. It allows the linkage to deform in the event of a severe rear wheel side impact, such as curb impact. In the event of a severe side impact, the linkage deforms, absorbing the impact energy and protecting the subframe from damage. The degree of deformation leads to the formation of excessive convergence, which immediately becomes noticeable to the driver.

The rear transverse link is attached to the subframe with an eccentric bolt and washer, which allow adjustment of the toe angle.

Both transverse links are attached to the subframe with bolts and locknuts. The outer ends of each rod are located in the mounting holes built into the wheel knuckle, and are fastened with bolts and locknuts.

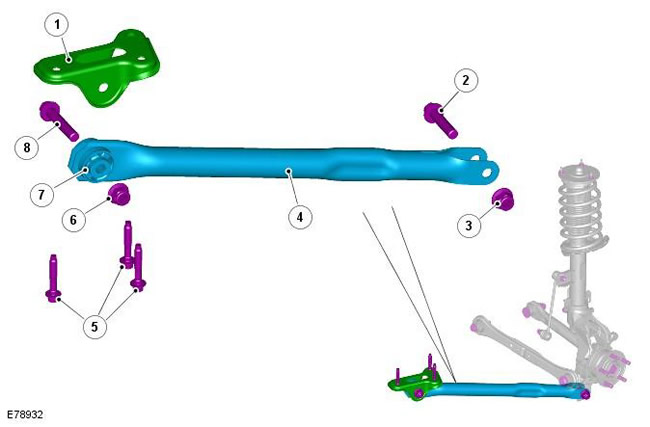

Longitudinal tie rod

| Pos. | spare part no | Name |

| 1 | - | Body Mounting Bracket |

| 2 | - | Bolt |

| 3 | - | Lock-nut |

| 4 | - | Longitudinal tie rod |

| 5 | - | bolts |

| 6 | - | Lock-nut |

| 7 | - | Sleeve |

| 8 | - | Bolt |

Longitudinal steering rods are made of pressed and cut pipe and are located between the wheel knuckle and the car body. The tie rods control the rear suspension in response to braking and traction forces.

The rear mount is fork-shaped and is located on each side of the bushing pressed into the wheel knuckle. The rod is attached with a bolt with a locknut passing through the bushing.

The front linkage mount is located in a bracket that is bolted to the underside of the car's body sill. The rod is equipped with a sleeve, which is installed in the bracket and secured with a bolt and locknut.

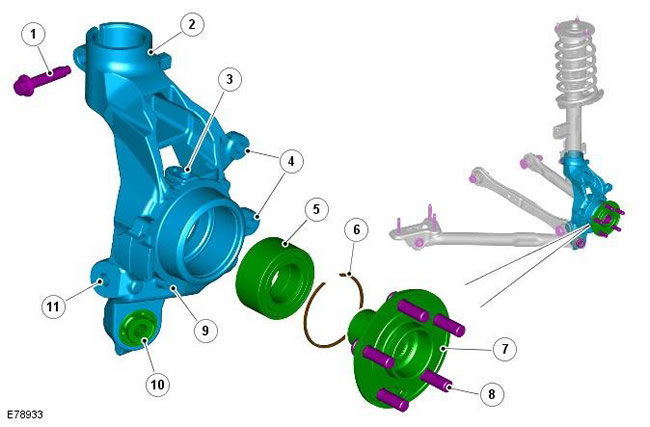

Wheel knuckle and hub

| Pos. | spare part no | Name |

| 1 | - | Clamp bolt |

| 2 | - | wheel fist |

| 3 | - | Anti-Lock Brake Wheel Speed Sensor (ABS) |

| 4 | - | brake caliper mount |

| 5 | - | Bearing |

| 6 | - | Retaining ring |

| 7 | - | Hub |

| 8 | - | hairpins |

| 9 | - | Disc shield mount |

| 10 | - | Tie Rod Bushing |

| 11 | - | Fastening of a forward cross-section steering draft |

The cast steel wheel knuckle secures the tie rods, tie rod, spring and damper assembly, wheel hub and bearing assembly.

The elongated lower protrusion on the knuckle has a pressed bushing and provides fastening of the longitudinal steering rod. The rod is attached to the knuckle with a bolt with a locknut passing through the rod and bushing.

Two additional protrusions on the inner surface of the wheel knuckle provide fastening of the front and rear transverse links, each of which is fastened with a bolt and locknut.

The upper part of the wheel knuckle has a mounting hole for the shock absorber body. The shock absorber body enters the hole and is located opposite the stop on the shock absorber body. The rear surface of the hole has a slot and allows you to fix the shock absorber body in the wheel knuckle with a clamping bolt.

There are places for installing a brake caliper and a brake disc shield. A hole is provided in the upper surface of the wheel knuckle for mounting the ABS wheel speed sensor, which is attached with a bolt.

The wheel hub assembly includes the wheel bearing and the ABS sensor pulse ring. The hub assembly is a non-serviceable item and must be replaced as a single unit.

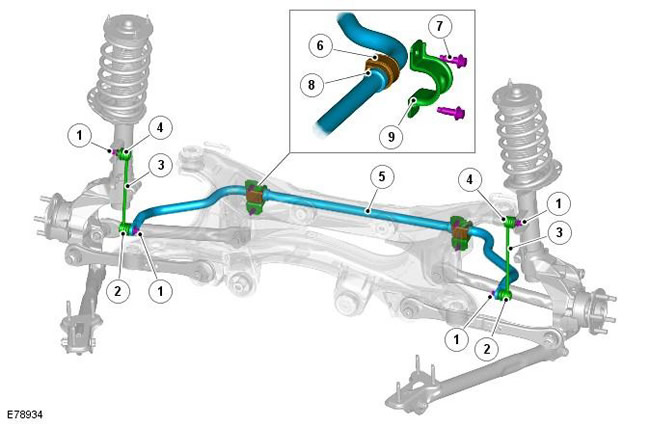

The bar of the stabilizer bar

| Pos. | spare part no | Name |

| 1 | - | Lock-nut |

| 2 | - | ball joint |

| 3 | - | Rack |

| 4 | - | ball joint |

| 5 | - | The bar of the stabilizer bar |

| 6 | - | Sleeve |

| 7 | - | Bolt |

| 8 | - | Ring |

| 9 | - | clamp |

The anti-roll bar is attached to the subframe with bushings and mounting brackets. Pressed steel brackets are located above the bushings and are bolted to the cross member through threaded holes in the subframe. The stabilizer bar has "stubborn" rings pressed on the inside of the bushings. The rings prevent lateral movement of the stabilizer bar.

The stabilizer is made of a manganese steel bar with a diameter of 22 mm. The ends of the stabilizer are bent forward to attach to the ball joint on the stabilizer link. Each stabilizer link is secured with a locknut to a bracket on the shock body. The struts are indistinguishable by mounting side and allow the stabilizer bar to move with the wheel travel for maximum efficiency. The stabilizer bushings are compressed type bushings that grip the stabilizer when compressed with clamps.

The stabilizer bushings are compressed type bushings that grip the stabilizer when compressed by mounting brackets. When replacing the bushings on the stabilizer, ensure that the bushings are correctly oriented with respect to the stabilizer. Incorrect bushing adjustment can result in excessive preload (twisting) in the bushings when the suspension is set to the nominal height position.

Comments on this article