Removing

1. Raise and lower the vehicle on jack stands.

2. Drain the transmission fluid. Refer to the procedure: Draining the gear oil from the differential and filling the differential with gear oil (205-02 Rear Drive Axle/Differential, General Procedures).

3. Remove the rear differential. Refer to Procedure: Differential Box (205-02 Rear drive axle / differential, Removal and installation).

4. Turn out bolts of a case of differential.

5. Remove the differential housing.

6. Remove and discard differential case seal.

7. Remove the ring gear assembly.

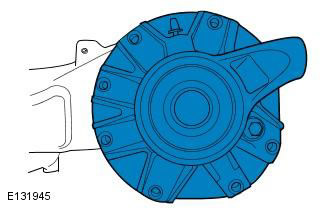

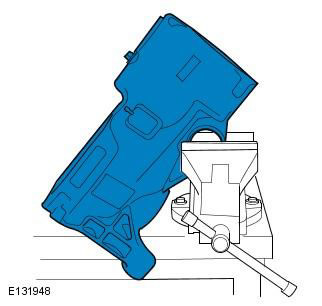

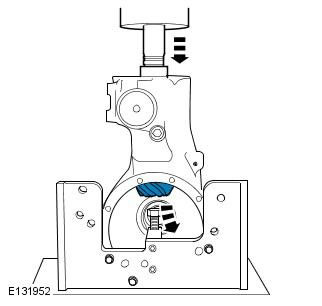

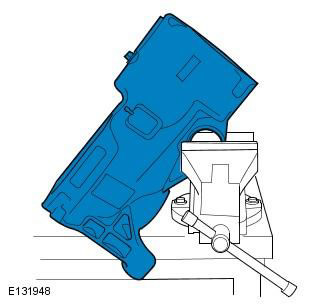

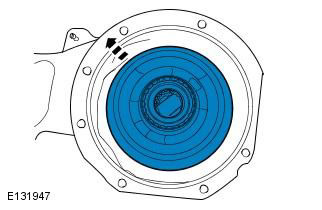

8. Clamp the differential assembly in a suitable vise as shown.

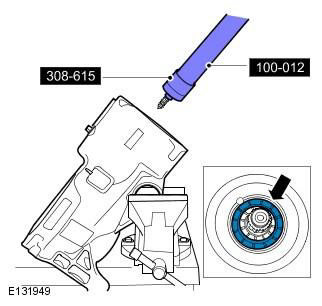

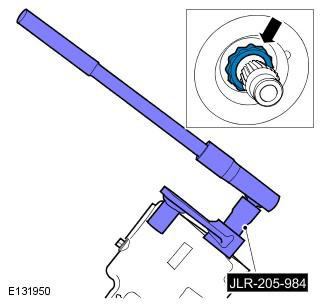

9. Using the special tool, remove the pinion shaft seal.

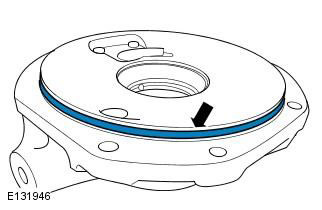

CAUTION: Make sure the drive gear recess is not damaged when the seal is removed.

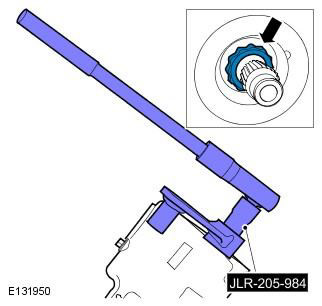

10. Using the special tools, remove the pinion shaft nut.

WARNING: Use of high torque.

CAUTION: Do not use pneumatic tools or heat to remove the nut (this can lead to contamination of the front bearing). Failure to follow this instruction may result in damage to this component.

NOTE: The special tool must be turned clockwise to remove the pinion shaft nut.

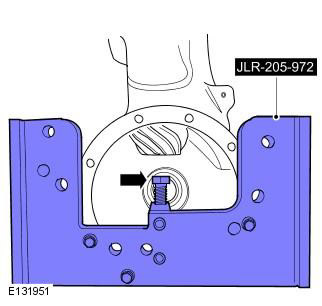

11. Fix the differential housing in the special tool. Place the support bolt in its lowest position.

12. Using a suitable press, remove the differential drive gear shaft.

CAUTION: Failure to use support plates to secure attachment to press may result in twisting or damage to the crankcase.

13. Remove and discard the pinion shaft pad.

14. Remove the rear bearing inner race.

15. Using the special tools, remove the pinion shaft rear bearing outer race.

16.

- Remove the differential from the mount.

- Thoroughly clean the pinion shaft, paying particular attention to the threads.

- Thoroughly clean the differential housings using a suitable cleaning fluid.

CAUTION: Working on the rear differential requires absolute cleanliness. Always cover all open openings with lint-free material to prevent penetration of foreign material. Failure to follow this instruction may result in damage to the elements.

Installation

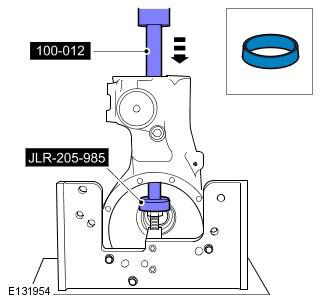

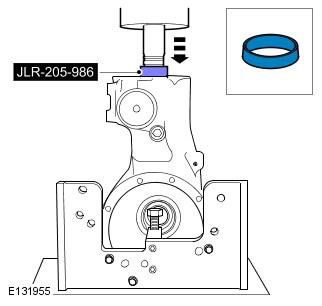

1.

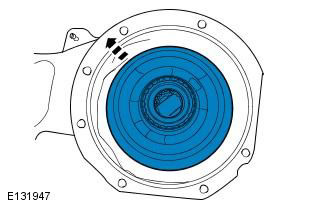

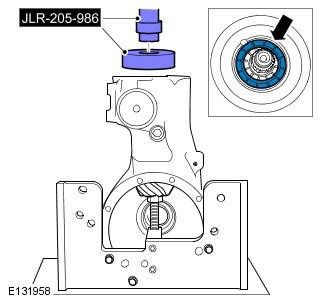

- Secure the differential housing with the special tool.

- Using a suitable press and the special tool, install the pinion shaft rear bearing outer race.

CAUTION: Do not clean or lubricate the new pinion shaft rear bearing, it is supplied with a low viscosity grease. Failure to do so will result in the need to replace the rear bearing before the differential is assembled.

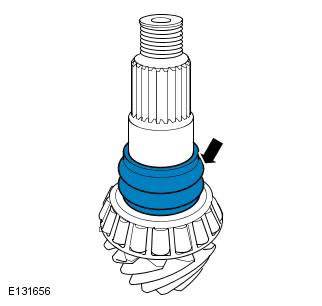

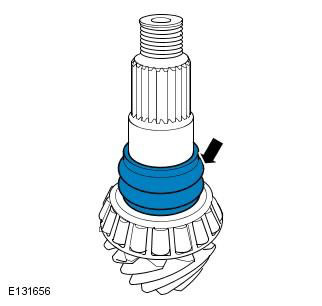

2. Install a new drive gear shaft seal.

3.

- Install the pinion shaft into the differential case.

- Lubricate the support bearing at the drive gear with differential oil.

- Place the support bolt in its highest position.

4. Using a suitable press and special tool, install the pinion shaft rear bearing inner race.

CAUTION: Do not clean or lubricate the new pinion shaft rear bearing, it is supplied with a low viscosity grease. Failure to do so will result in the need to replace the rear bearing before the differential is assembled.

5. Clamp the differential assembly in a suitable vise as shown. Remove the differential from the mount.

6. Using the special tools, install a new pinion nut. Tighten to 250 Nm (184 lb/ft).

WARNING: Use of high torque.

The special tool must be turned counterclockwise to install the pinion shaft nut.

Do not use a pneumatic tool to install the nut. Failure to follow this instruction may result in damage to this component.

NOTE: The drive gear shaft gasket starts to buckle at a minimum torque of 250 Nm (184 lb/ft).

7.

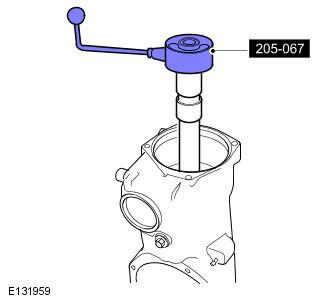

- Using a special tool, check the torque required to rotate the drive gear shaft. recommended torque 1.1+/-0.2 Nm

- If the specified torque to rotate the pinion shaft is not reached, use the special tools to tighten the flange nut in one degree increments, checking the torque after each step, until the recommended torque 1.1+/-0 is reached.2 Nm

Make sure that the specified torque when rotating the shaft is not exceeded. If excessive preload is applied to the joint, the pinion shaft must be removed and a new deformable spacer, pinion shaft rear bearing, pinion shaft rear bearing outer race, and pinion nut installed.

To obtain a constant value, the special tool should be rotated at a speed of 60 rpm (1 revolution per second).

Before measuring the torque, the drive gear shaft should be turned by hand two full turns.

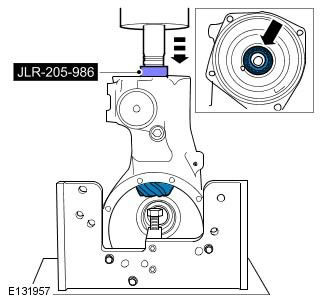

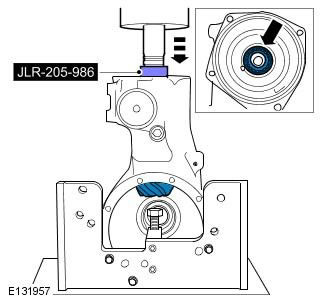

8. Using a suitable press, special tool and adapter, install the pinion bearing seal.

CAUTION: Do not lubricate the drive gear oil seal.

9. Install ring gear assembly.

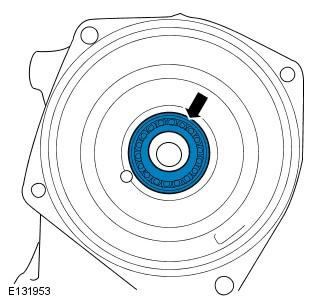

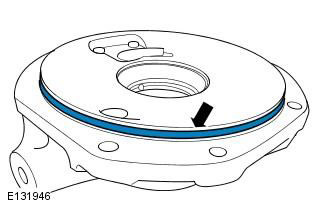

10. Establish an epiploon of a case of differential. Apply a small amount of clean differential oil to the new oil seal.

Make sure mating surfaces are clean, failure to do so may result in damage to the differential.

Make sure that the new oil seal is not twisted during installation, failure to do so may damage the differential.

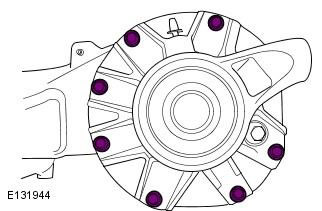

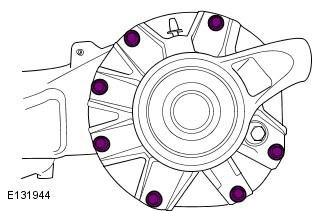

11. Screw bolts of a case of differential. Tighten the 7 bolts to 29 Nm.

12. Install the rear differential. Refer to Procedure: Differential Box (205-02 Rear drive axle / differential, Removal and installation).

13. Fill the differential housing with working fluid. Refer to the procedure: Draining the gear oil from the differential and filling the differential with gear oil (205-02 Rear Drive Axle/Differential, General Procedures).

Comments on this article