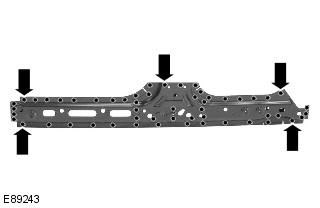

The internal reinforcement of the bottom trim panel is made of DP600 steel (duplex steel) and must be welded to the inside with MIG electric rivets. Spot welding should not be used.

Make sure all welded joints are properly sealed and protected from water penetration, especially in areas where the adhesive/seal of the original panel cannot be replicated. Seal joints before installing exterior panels where necessary.

NOTE: The internal reinforcement of the lower trim panel is torn off "ring frame" side panel amplifier, it is not serviceable separately.

Removing

1. In combination with the internal reinforcement of the lower trim panel, it is replaced by:

- front bumper cover

- Front fender

- Front door

- Backdoor

- Bottom trim panel

2. For more information regarding this repair procedure, see: For more information, refer to the chapter: Body and frame (501-26 Body Repairs - Vehicle Special Information and Approval Checks, Description and Operation) / Standard techniques used at the service station (100-00 General information, Description and principle of operation).

3. Remove the bottom trim panel. For more information, see chapter: Bottom rail panel (501-29 Side panel sheet metal repairs, Removal and installation).

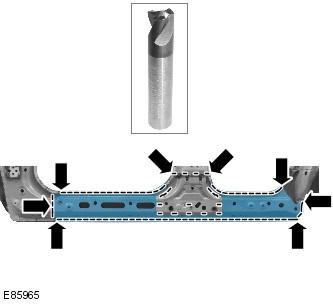

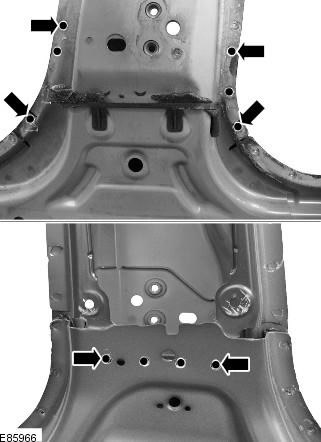

4. Drill out the spot welds, this will require the use of an HSS spot weld drill.

5. If the amplifier rack "IN" has not been removed, you will need to disconnect it.

- Mill out the spot welds.

- Split this connection and release the rack amp "IN" forward so you can remove the bottom trim panel inner reinforcement.

6. Separate the connections and remove the old panel.

Installation

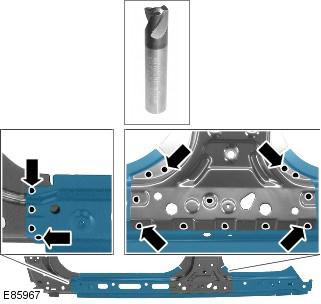

1. Remove the bottom trim panel reinforcement part from the side panel reinforcement annular frame, serviced panel. Drill out the spot welds using the HSS spot weld drill.

2. Prepare the connecting surfaces of the old and new panels.

3. Attach the new panel and lock it in place. Check the reconciliation, if correct, go to the next step, if not, correct and check again before proceeding to the next step.

4. Welding with electric MIG rivets.

NOTE: The holes for the MIG electric rivets are made by removing the old panel and separating the serviced panel.

NOTE: MIG electric rivets should be installed in place of the original spot welds and, where possible, they should extend through the inside of the bottom trim panel.

5. Clean all welds.

6. Reverse the removal procedure to install the appropriate panels and mechanicals.

Comments on this article