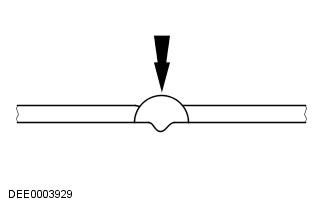

Butt joint

NOTE: Separating cuts for sectional replacement should be as short as possible. Cutting can only be done along the cut lines shown in the repair diagrams.

It is forbidden to make cuts near reinforcements or along predetermined fold lines.

Prepare parts left on the vehicle and new parts

- Restore the original shape of the adjacent surface of any dented body parts that should remain on the vehicle using a hammer and mating tool (ensures shape conformity "old" element and new element). Remove, using an angle grinder, spot or other welds.

- Cut out new pieces to shape.

- If necessary, punch or drill holes for MIG welding.

NOTE: Do not use welding torch to remove paint residue (heat can cause deformation of the metal).

- On both sides, clean all connecting flanges to bare metal. Do not use an angle grinder for this purpose (this can weaken the metal and damage the zinc layer). Required tools: Rotating wire brush, belt sander or plastic disc.

- Apply a sufficient amount of welding primer to the surfaces to be welded.

- The primer should be well mixed before use.

NOTE: When using aerosols, be careful not to contaminate adjacent areas.

Install a new element

Make sure that the new element exactly corresponds to the prescribed dimensions. Related equipment:

- Right slipway.

- Universal measuring system.

- slipway.

- Measurement with a ruler or tape measure.

- Compass.

- Frame dimensions can be found in the repair manuals for specific models.

NOTE: Any attached body parts that require precision alignment and installation, such as bumpers, seals, headlights, taillights, and lock assemblies, should be installed at this stage. Careless work can result in water leaks, wind noise intrusion and a significant amount of extra work.

Make sure the edges are aligned with adjacent elements and check for correct gaps (compare left and right sides). Make sure the shape of the car is maintained.

Pinning a new element

NOTE: Additional work can be greatly reduced if alignment and tack welding operations are performed with due care.

Depending on availability, the following fixing methods are available:

- Crimping tool set.

- Set of screw clamps.

- Self-tapping screws.

- Tack seams.

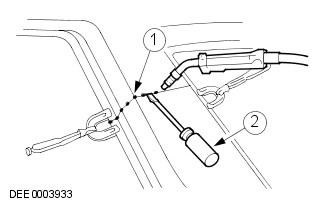

Use a center punch or screwdriver to ensure that the edges of the profiles line up when replacing in sections. The edge is then tack welded to ensure it is in the correct position.

Alignment and tack welding

| Pos. | spare part no | Name |

| 1 | - | Tack weld locations |

| 2 | - | Using a screwdriver to align the position |

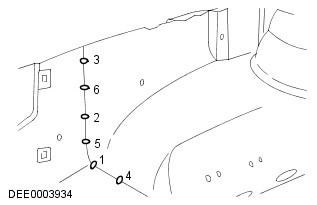

Longer joints are usually tack welded to prevent warping of the panel. It is important to carry out tack welds in the correct sequence (see diagram). Weld the new element following the instructions in the repair manual.

Correct tack welding sequence

Continuing Repair/Corrosion Protection

This section is mainly devoted to the following work:

- Cleaning of welds.

- Bare metal primer.

- Sealing of welds.

- Applying a protective coating to the bottom.

- Installation of damping lining.

- Filling cavities with cavity sealant.

NOTE: For information on cavity sealant application areas, see "Corrosion protection".

Comments on this article