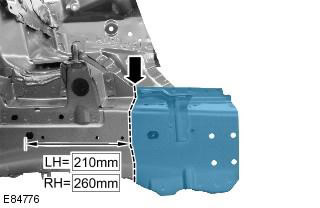

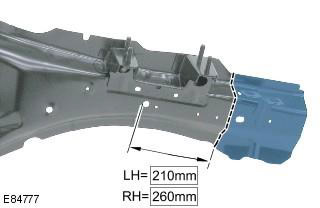

NOTE: The front side member section is cut off from the front side member service panel.

NOTE: The right section is slightly shorter than the left due to the location of the engine mount.

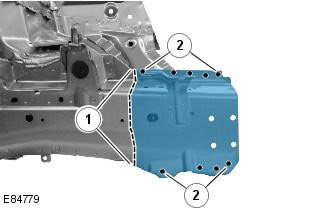

NOTE: Due to the combined thickness of the panels, it is recommended that the spot welds be replaced with electric MIG rivets when making this repair.

1. When replacing the front side member section, the following elements are removed:

- front bumper cover

- Front bumper mount

- Hood latch panel

- Both front fenders

- Front bumper support

NOTE: It is also necessary to remove the engine and suspension as a unit.

2. For more information on this repair procedure, refer to the following sources: For more information, refer to the chapter: Body and Frame (501-26 Body Repairs - Vehicle Special Information and Approval Checks, Description and Operation) / Standard techniques used at the service station (100-00 General information, Description and principle of operation).

3. Remove the front bumper support. For more information, refer to the chapter: Front bumper mounting (501-27 Repairs of sheet metal elements of the front end, Removal and installation).

4. Remove the radiator cooling block. For more information, see chapter: Radiator (303-03A Engine cooling - 3.2L NA - I6, Removal and installation).

5. Remove the engine and front suspension as a single unit.

6. Left side: Remove the air intake duct.

7. Left side: Loosen the battery electrical junction box and place it aside.

8. Right side: Remove the windshield washer reservoir. For more information, see chapter: Windshield washer reservoir (501-16 Windshield wipers and washers, Removal and installation).

9. Release the wiring harness and set it aside.

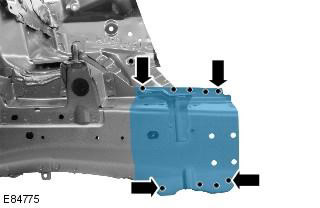

10. Mill out the contact welding points.

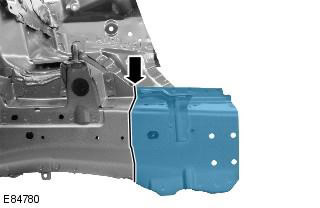

11. Cut off the old panel at the location shown.

12. Separate the connections and remove the old panel.

Installation

1. Saw off a new section from the service panel; the cut should be aligned with the cut on the old panel.

2. Prepare the mating surfaces of the old and new panels.

3. Drill holes in the new panel in preparation for MIG electric rivet welding.

4. Position the new panel in the desired location and secure it. Check position alignment. If it is correct, go to the next paragraph. If not, make any necessary adjustments and recheck before continuing.

5. After fixing the panels:

- 1. Make tack welds for the butt joint.

- 2. Weld with electric rivets using MIG technology.

6. Clean up the tack welds.

7. Make a MIG butt weld.

8. Clean all welds.

9. Installation of the corresponding panels and mechanical elements is carried out in the reverse order of removal.

Comments on this article