Disassembly

1. Remove the crankshaft.

ENGINE KV6 - MODIFICATION K, Piston group, Crankshaft.

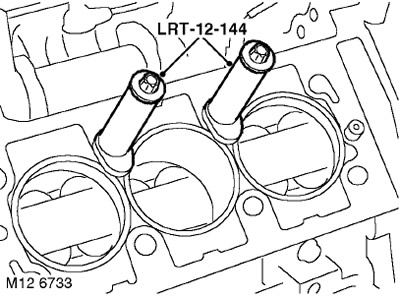

2. Remove the LRT-12-144 cylinder liners from the cylinder block.

3. Mark position of sleeves of cylinders concerning the block of cylinders.

4. Using a partner, position the cylinder block so that the pistons and cylinder liners can be removed.

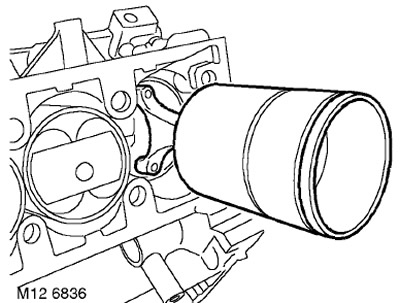

5. Carefully remove the piston liners from the cylinder block.

ATTENTION: Mark the pistons and sleeves so that each piston then fits into its own sleeve.

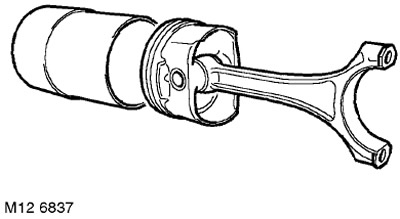

6. Remove the pistons from the sleeves. Arrange the sleeves in the order in which they were installed on the engine.

7. Place the connecting rod caps back on the connecting rods and lightly tighten the fitting bolts.

8. Using a ring expander, remove the rings from the pistons and discard them.

9. With the end of the broken off old ring, clean the piston grooves from carbon deposits.

Examination

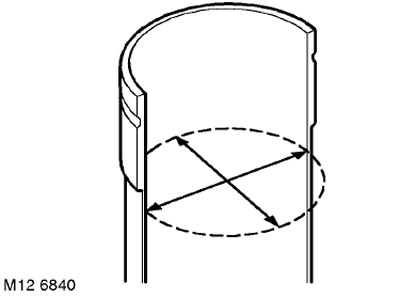

1. Cylinders: Measure wear in two planes at a distance of 65 mm from the top end of the sleeve. The size group of the cylinder is marked on the outer surface of the sleeve.

CAUTION: Cylinder liners that are excessively rubbed, worn, scratched or torn must be replaced. DO NOT ATTEMPT to hone or remove chafing from the cylinder bore surface. If you intend to continue using old cases, then you should save the position marks when removing the cases.

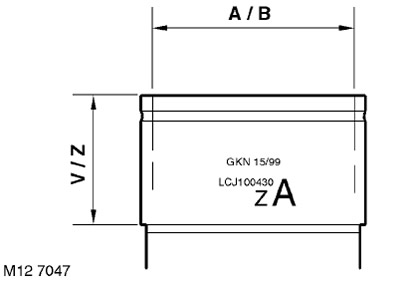

2. The size group of the cylinder diameter and landing height are determined by the manufacturer. Size group of diameter (red, A or B, blue) and landing height group (V or Z) are applied to the outer surface of the sleeves along with the part number and color code. If the sleeve (cartridge cases) cylinders to be replaced, then a new sleeve (cartridge cases) must have the same landing height group as the one being replaced. Any cylinder diameter size group is supplied in two seat height size groups.

TECHNICAL CHARACTERISTICS, Engine - petrol KV6.

3. Check pistons for damage and cracks.

NOTE: The designation of size groups A or B is stamped on the upper plane of the piston crown.

4. Piston diameter measurement: Measure the piston skirt diameter at right angles to the piston pin axis, 8 mm from the bottom edge of the skirt.

TECHNICAL CHARACTERISTICS, Engine - petrol KV6.

NOTE: Piston is only shipped complete with connecting rod.

CAUTION: Pistons must be installed in their original sleeves.

5. Insert the piston into the cylinder liner and measure the clearance at a distance of 20 mm from the bottom of the liner.

TECHNICAL CHARACTERISTICS, Engine - petrol KV6.

6. Piston ring gap: Insert new first and second compression rings into the cylinder, 20 mm from the top of the liner, and measure the ring gap.

TECHNICAL CHARACTERISTICS, Engine - petrol KV6.

ATTENTION: The rings must be in a plane perpendicular to the axis of the cylinder. The rings must be installed on the piston of the cylinder where they were checked.

7. Piston ring installation: Install the oil scraper ring expander.

8. Turn the rings with the mark 'TOP', or other mark, up, using ring pliers, put on the piston: oil scraper ring, 2nd compression ring and top compression ring.

NOTE: The second compression ring is a scraper type.

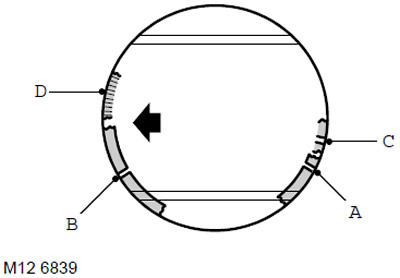

9. Check the free movement of the rings in the grooves and spread the locks A and B of the compression rings at an angle of 120 degrees to each other and away from the loaded part of the piston. The gap C of the oil scraper ring and the lock D of the ring expander are bred opposite each other, in a plane located at an angle of 30°to the axis of the piston pin.

10. Check up axial backlashes between rings and piston grooves.

TECHNICAL CHARACTERISTICS, Engine - petrol KV6.

Assembly

1. Thoroughly wash the cylinder liners and their seats in the block.

2. Lubricate the cylinder mirror, pistons and rings with clean engine oil, check that the ring locks are separated from each other at the desired angle.

3. Wipe the bed liners in the connecting rods and in the connecting rod caps.

4. Place the LRT-12-204 ring crimping tool on the piston and insert the piston into your cylinder liner so that the arrow on the piston crown faces the front of the engine when installed on the engine. Do this operation with the rest of the pistons.

CAUTION: Do not push the pistons far down at this stage.

5. Remove the crimp tool.

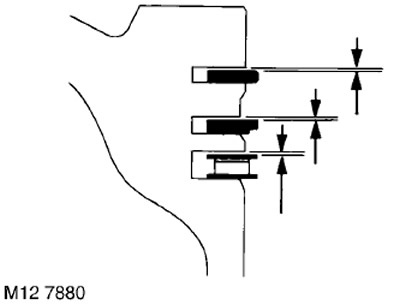

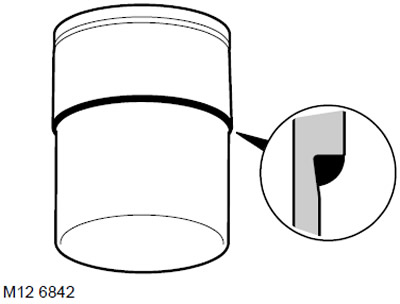

6. Apply a continuous bead of 2 mm thick RTC 3347 sealant to the shoulder of each sleeve as shown.

7. Holding the liner perpendicular to the cylinder block, insert the liner into the socket until the seat belt rests against the block, paying attention to the fact that the arrow on the piston crown must face the front of the engine.

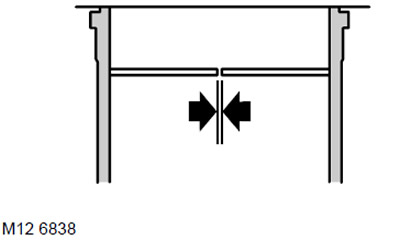

8. To prevent the liners from moving, install the LRT-12-144 mounts on the cylinder block and secure them with cylinder head bolts. The base of the cylinder liners must not protrude above the cylinder surface.

9. Install the crankshaft.

ENGINE KV6 - MODIFICATION K, Piston group, Crankshaft.

Comments on this article