Dismantling

1. Remove connecting rod bearings.

ENGINE - MODIFICATION K, volume 1.8, Front seal of the exhaust camshaft, Replacement of connecting rod bearings.

2. Remove carbon deposits from the top of the cylinders.

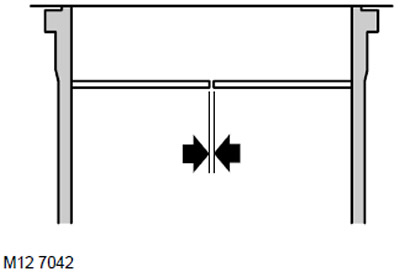

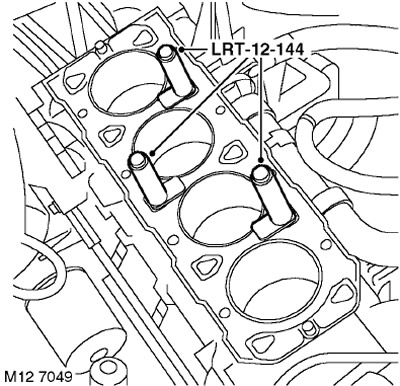

3. Do not allow LRT-12-144 cylinder liner mounts to protrude above the cylinder mirror.

4. Mark the pistons with the connecting rods so that they can then be installed in their original places.

5. Carefully push the pistons towards the top of the cylinders.

6. Carefully push the pistons out, making sure that the lower heads of the connecting rods do not touch the cylinder mirror. WARNING: Removing the pistons entails replacing the cylinder liner seals.

7. Using special pliers, remove the rings from the pistons and discard the rings.

Installation

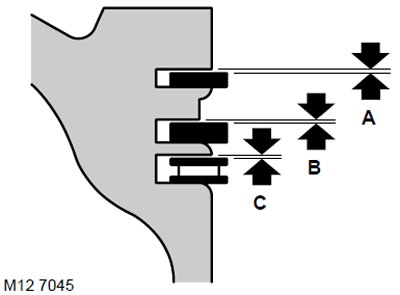

1. Clean the piston ring grooves and blow out the oil holes in the ring grooves.

2. Having installed the rings at a distance of 20 mm from the upper cut of the cylinder liner, as shown in the figure, check the gap in the lock of the rings.

TECHNICAL CHARACTERISTICS, Engine - gasoline K1.8.

ATTENTION: The gap in the lock of the rings must be checked strictly in the cylinder for which these rings are intended.

3. Check pistons for damage and cracks.

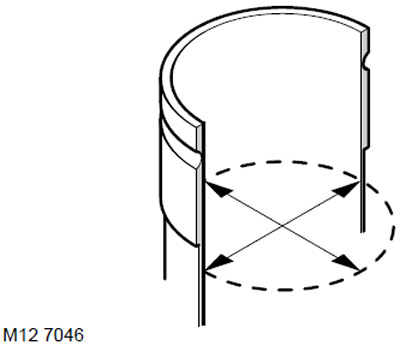

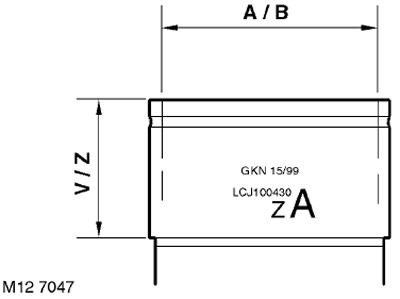

4. Measure the diameter of the piston skirt at right angles to the axis of the piston pin, at a distance of 8 mm from the bottom cut of the skirt.

TECHNICAL CHARACTERISTICS, Engine - gasoline K1.8.

NOTE: The designation of size groups A or B is stamped on the upper plane of the piston crown.

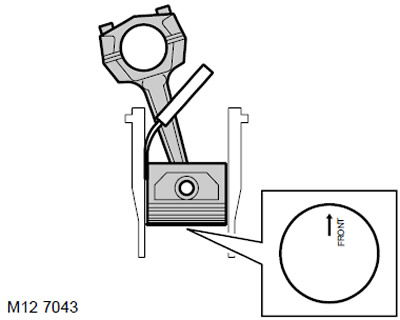

5. Starting with the piston of the first cylinder, check the gap between the skirt and the cylinder mirror. Turn the piston upside down and insert it into the cylinder, with the 'FRONT' mark or arrow on the bottom facing the REAR of the engine.

ATTENTION: Each of the pistons must be checked in its own cylinder.

6. The bottom edge of the piston skirt should be 30 mm from the top of the cylinder liner.

7. Using a feeler gauge, measure and record the clearance between the piston and the left side of the cylinder liner (viewed from the front of the engine).

TECHNICAL CHARACTERISTICS, Engine - gasoline K1.8.

8. Do this procedure with the rest of the pistons.

NOTE: Piston is only shipped complete with connecting rod.

9. Install the expander on the oil scraper ring.

10. Turn the rings with the mark 'TOP', or other mark, up, using ring pliers, put on the piston: oil scraper ring, 2nd compression ring and top compression ring.

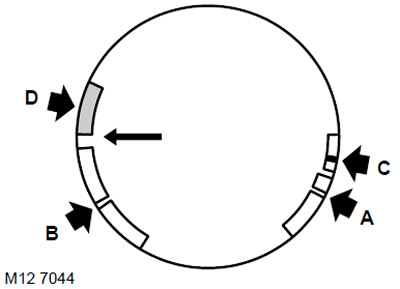

11. Check the freedom of movement of the rings in the grooves and spread the locks A and B of the compression rings at an angle of 120°to each other and away from the loaded part of the piston. The gap C of the oil scraper ring and the lock D of the ring expander are separated opposite each other, in a plane located at an angle of 30°to the axis of the piston pin.

12. Check up a backlash between a new ring and a piston flute.

TECHNICAL CHARACTERISTICS, Engine - gasoline K1.8.

13. Turn out bolts from fastenings of sleeves of cylinders LRT-12-144 and remove fastenings. If the old cylinder liners are to be used, mark the position of each liner relative to the cylinder block with a felt-tip pen. DO NOT scratch or score cylinder liners.

CAUTION: Store the cylinder head bolts in the order in which they were on the assembled engine.

14. By force of a hand push a sleeve outside, in a direction of a head of cylinders.

15. Measure the wear and taper of the sleeves in both directions, at a distance of 65 mm from the top cut of the sleeve. RED group = 80.000-80.015 mm. BLUE group = 80.016-80.030 mm. Size groups A and B are marked on the outside of the cylinder liners.

CAUTION: Cylinder liners that are excessively rubbed, worn, scratched or torn must be replaced. DO NOT ATTEMPT to hone or remove chafing from the cylinder bore surface. If you intend to continue using old cases, then you should save the position marks when removing the cases.

16. The size group of the cylinder diameter and landing height are determined by the manufacturer. Size group of diameter (red, A or B, blue) and landing height group (V or Z) are applied to the outer surface of the sleeves along with the part number. If the sleeve (cartridge cases) cylinders to be replaced, then a new sleeve (cartridge cases) must have the same landing height group as the one being replaced. Any cylinder diameter size group is supplied in two seat height size groups.

17. Remove any remaining sealant from the cylinder block and cylinder liner shoulder (if it is intended to be used).

18. Wash the cylinder liners and wipe them dry.

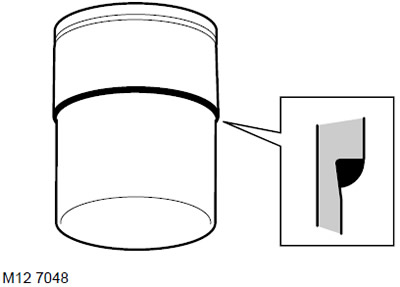

19. Apply a continuous bead of 2 mm thick RTC 3347 sealant to the shoulder of each sleeve as shown.

20. Holding the sleeve at a right angle to the top surface of the block, slide the sleeve into the block until it rests with the collar against the seat belt. DO NOT allow the liner to fall into the cylinder block.

21. Install the cylinder liner fasteners with the nylon nuts included in the kit, LRT-12-144, on the cylinder block and secure them with the cylinder head mounting bolts. The base of the cylinder liners must not protrude above the cylinder surface.

ATTENTION: The bolts used must be screwed into the same sockets in which they were on the assembled engine.

22. Lubricate the cylinder mirror, pistons and rings with engine oil, check that the ring locks are separated from each other at the desired angle.

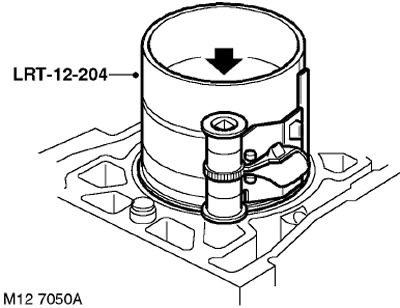

23. Alternately, crimp the rings on each of the pistons with a mandrel, LRT-12-204 and, turning the piston with the 'FRONT' mark stamped on the bottom forward, insert the pistons into their cylinders so that the bottom is flush with the top cut of the sleeve. Remove the ring crimp tool.

24. Install connecting rod bearings.

ENGINE - MODIFICATION K, volume 1.8, Front seal of the exhaust camshaft, Replacement of connecting rod bearings.

Comments on this article