Dismantling

1. Disconnect "negative" battery terminal.

2. Remove the oil pump.

ENGINE - Td4, Intake and exhaust camshafts, Oil pump.

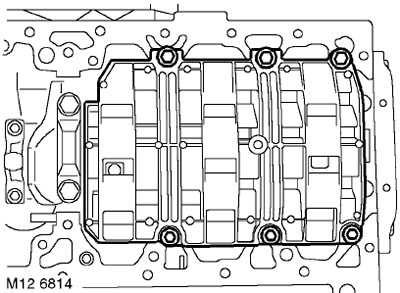

3. Turn away 6 bolts of fastening of the bottom plate of the block of cylinders and remove a plate.

4. Rotate the crankshaft to expose the connecting rod bolts.

5. Mark connecting rods and connecting rod caps by cylinder number.

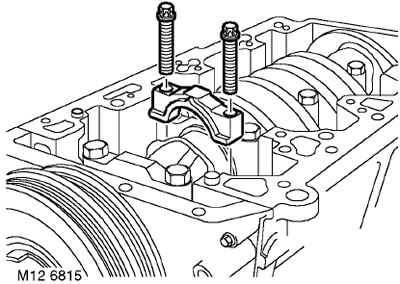

6. Loosen and remove the connecting rod bolts, save them for now.

CAUTION: The connecting rod caps are mounted on pins. Avoid side impacts on covers.

7. Remove connecting rod caps, remove and discard connecting rod bearings.

8. Rotate the crankshaft to allow the connecting rod to move away from the journal.

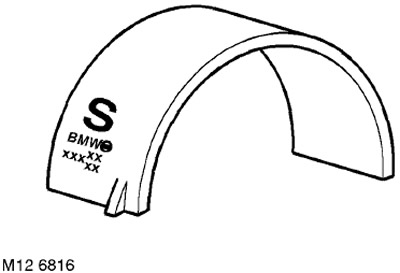

9. Remove and dispose of the upper connecting rod bearings, making sure that there is a mark "S" on their backside.

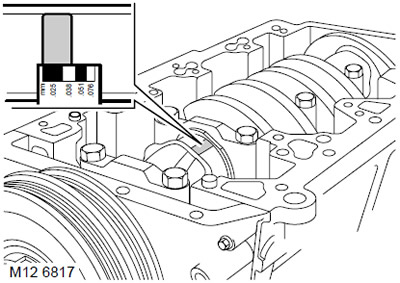

ATTENTION: The upper connecting rod bearings are run-in coated and are marked with the letter "S" or next to icons "xxx" on its back side.

10. Do the same with the rest of the connecting rod bearings. Lay out the connecting rod caps in the order they were on the engine.

Installation

1. Wipe the crankpins, new liners, beds of the upper and lower liners.

2. Measure the diameter of each crankpin in four directions at 90°intervals. Record the measurement results.

TECHNICAL DATA, Engine - Diesel Td4.

3. Wipe the connecting rod bolts and lubricate them with engine oil.

4. Turn the crankshaft so that the connecting rod journals of the first and fourth cylinders are at BDC.

5. Install new eartips marked in BLUE and with the letter "S", into the connecting rods of the first and fourth cylinders.

6. Install new liners marked in RED into the connecting rod caps of the first and fourth cylinders.

7. Put both connecting rods on the crankpins.

8. Place on the connecting rod journals of the first and fourth cylinders, in the axial direction, strips of a deformable caliber.

9. Aligning the marks, install the connecting rod caps in their places.

10. Screw in the old connecting rod bolts and tighten them: Step 1: 5 Nm. Stage 2: 25 Nm. Step 3 - Using an angle torque wrench, tighten the bolts 70°.

11. Remove the connecting rod bolts and remove the connecting rod caps.

12. Using a special ruler, measure the width of the deformable calibers and determine the clearance in the connecting rod bearings.

TECHNICAL DATA, Engine - Diesel Td4.

13. If the used connecting rod bearings cannot provide the required clearance, then the connecting rod journals must be ground to the next repair size and the appropriate repair bearings must be used.

14. Leave the bearings recognized as suitable in their places, in the connecting rods and in the connecting rod caps of the first and fourth cylinders.

15. With a rag moistened with engine oil, wipe off all remnants of the deformable caliber from the surface of the connecting rod journals.

16. Repeat the above operations on the second and third cylinders.

17. After checking the clearances in the connecting rod bearings is completed, dispose of the used connecting rod bolts.

18. Lubricate the connecting rod journals and approved connecting rod bearings with clean engine oil.

19. Install the liners selected for use in the connecting rods and in the connecting rod caps, paying attention, however, to the fact that those marked with the letter "S".

20. Lower the connecting rods onto the connecting rod journals, paying attention to the correct position of the liners.

21. Aligning the marks, install the connecting rod caps in their places.

22. Lubricate new connecting rod bolts with clean engine oil.

23. Screw in new connecting rod bolts and tighten them: Stage 1: 5 Nm. Stage 2: 25 Nm. Step 3 - Using an angle torque wrench, tighten the bolts 70°.

24. Wipe down the bottom plate and counter mating surface.

25. Replace the bottom plate, install the bolts and tighten them evenly. Tightening torque 22 Nm.

26. Install the oil pump.

ENGINE - Td4, Intake and exhaust camshafts, Oil pump.

27. Attach "negative" battery terminal.

Comments on this article