Dismantling

1. Place the vehicle on a two post lift.

2. Disconnect "negative" battery terminal.

3. Fix a cowl in vertical position.

4. Drain the engine coolant.

COOLING SYSTEM: Td4 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

5. Remove air hoses of inlet system.

6. Remove the battery pad.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Support tray - storage battery.

7. Remove the engine control unit (ECM).

ENGINE CONTROL SYSTEM: EDC, REPAIR WORK, Engine control unit (ECM).

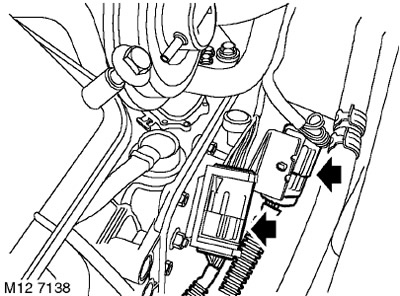

8. Disconnect the connector from the automatic transmission control unit.

9. Disconnect the connector from the glow plug control unit.

10. Disconnect the multi-position connector of the engine control harness from the junction box.

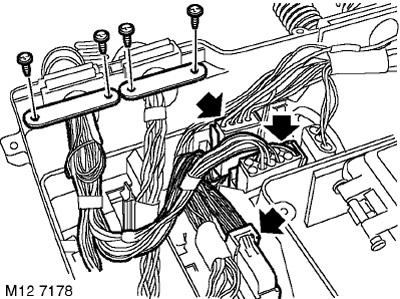

11. Loosen the four screws and remove the wire harness clamps.

12. Disconnect the engine harnesses from the junction box and lay them on top of the engine.

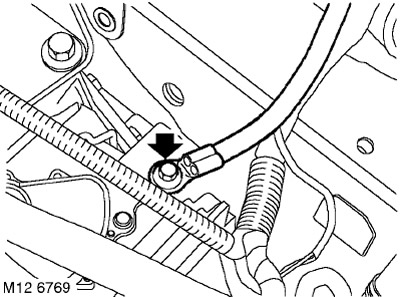

13. Turn out a bolt and disconnect the tire "masses" from the gearbox.

14. Unfasten the two transmission harness connectors and disconnect them.

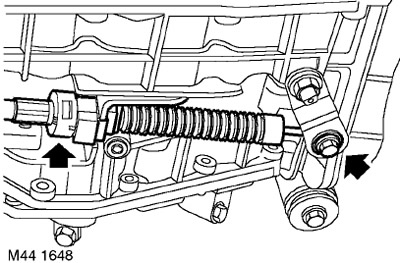

15. Loosen the nut securing the selector cable to the box lever.

16. Remove the clip, disconnect the selector cable and remove the lever.

17. Remove the cap from the pole piece and disconnect the two wires from the starter retractor.

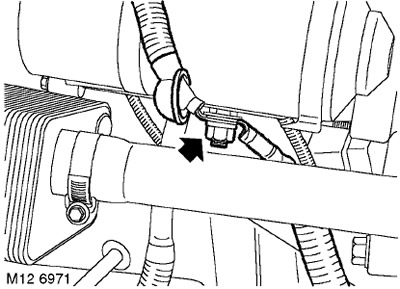

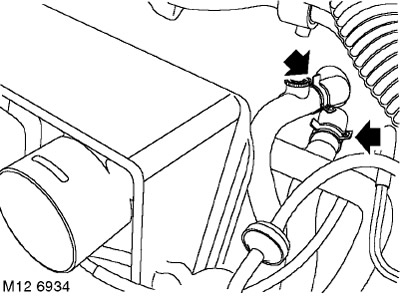

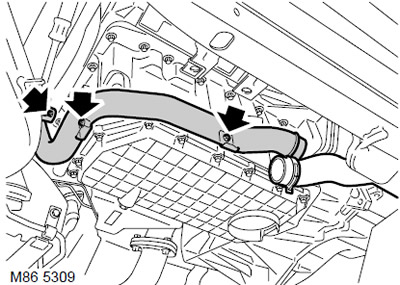

18. Loosen the clamp and disconnect the air hose leading to the intercooler from the engine.

CAUTION: Before disconnecting or removing system components, make sure that the surfaces adjacent to the connection points are free of dirt. Install plugs in fittings and piping to keep dirt out of the system.

19. Prepare containers to collect residual fuel.

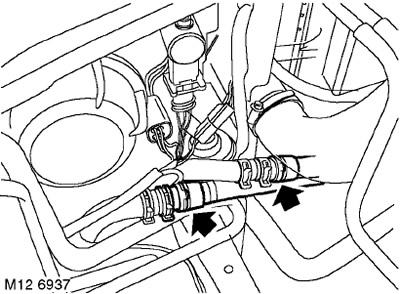

20. Turn away collars and disconnect fuel hoses from a fuel stage.

21. Loosen the clamp and disconnect the top hose from the radiator.

22. Turn away a collar and disconnect a hose from a distributive tube of system of cooling.

23. Loosen 2 clamps and disconnect the hoses from the heater.

24. Place a container under the transmission heat exchanger hoses to collect the fluid.

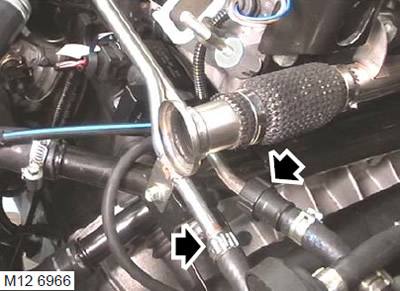

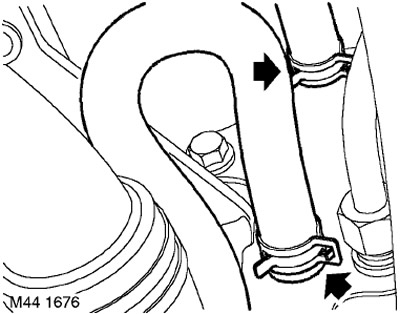

25. Loosen the two clamps and disconnect the cooling system hoses from the transmission heat exchanger.

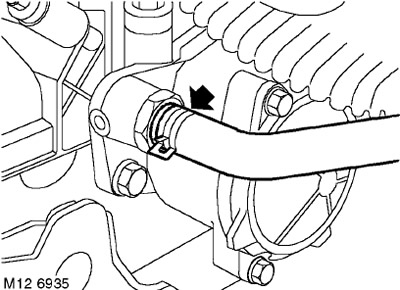

26. Turn away a bolt of fastening of a collar of a tube of the hydraulic booster to an eye.

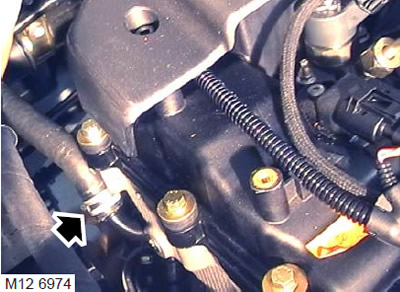

27. Loosen the clamp and disconnect the vacuum hose from the vacuum pump.

28. Mark the location of the vacuum tubes and remove both vacuum tubes from the reservoir.

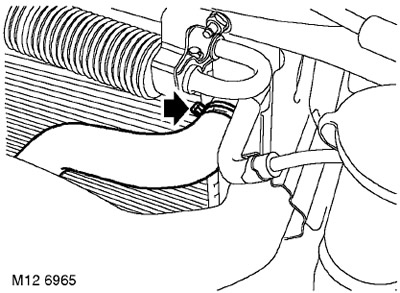

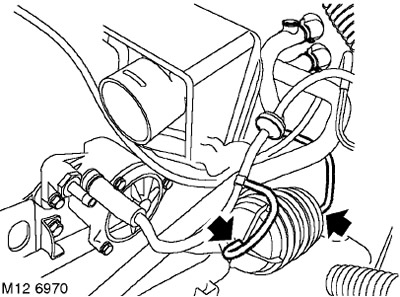

29. Loosen the clamps and remove the inlet and outlet hoses from the flare heater (FBH).

30. Remove a back cross beam.

FRONT SUSPENSION, REPAIR WORKS, Front subframe.

31. Drain the gearbox oil.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Replacement of the working fluid in the box.

32. Drain the oil from the transfer case.

TRANSFER BOX, ADJUSTMENTS, Changing the transmission oil in the transfer case: except for the North American market.

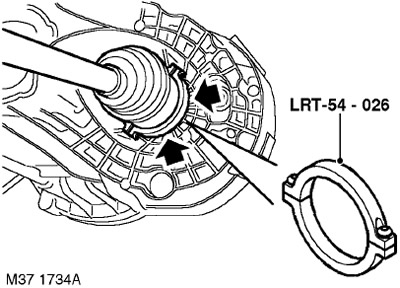

33. Install tool LRT-54-026 on the drive shaft inner joint. Using the lever, release the drive shafts from the transfer case and gearbox.

34. With the help of a partner, move the hubs outward and remove the drive shafts from the transfer case and from the gearbox.

35. Remove a reception pipe of system of release.

MANIFOLDS AND EXHAUST SYSTEM - Td4, REPAIR WORK, Downpipe.

36. Raise one rear wheel so that the driveshaft can be rotated to gain access to the bolts.

37. To facilitate subsequent assembly, mark the position of the viscous coupling in relation to the transfer case flange.

38. Turn away 6 nuts and remove bolts of fastening of a cardan shaft to a leading flange of a distributing box.

Remove the driveshaft from the transfer box drive flange and tie it aside.

CAUTION: Care must be taken when removing the three-roller joint from the transfer case. In order not to damage the cover, it must not be fully stretched, the hinge body must be protected from shock.

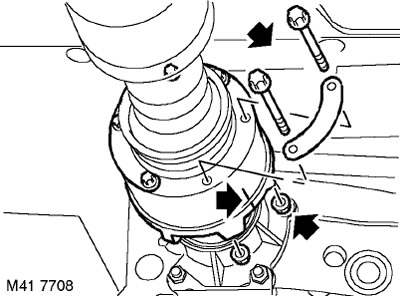

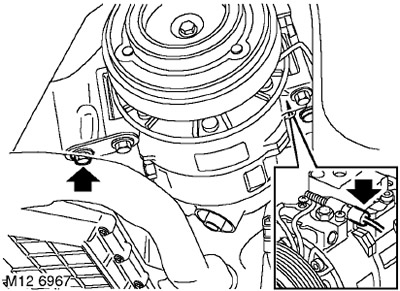

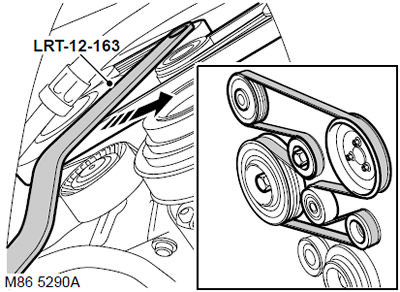

40. Models with air conditioning system: Loosen the axle and bolt of the A/C compressor belt tensioner.

41. Models with A/C system: Remove the belt from the compressor pulley.

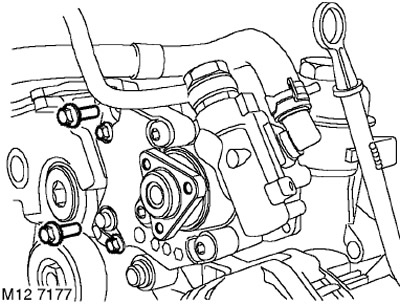

42. Models with A/C system: Loosen the bolt securing the compressor bracket to the sump, but do not remove it.

43. Models with air conditioning: Disconnect the connector from the compressor.

44. Models with air conditioning system: Remove the three bolts securing the distribution tube to the sump and to the cylinder block.

45. Models with air conditioning system: Remove the 3 bolts securing the air conditioning compressor to the bracket, move the compressor to the side and fix it.

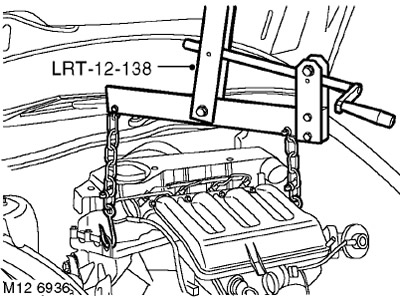

46. Install the LRT-12-138 traverse onto the lifting chains and hook them onto the engine lifting eyes.

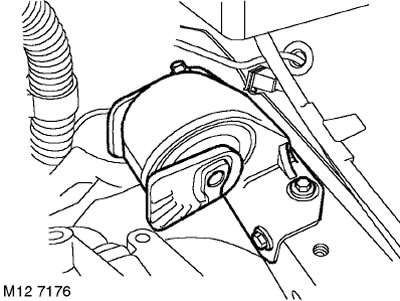

47. Remove the hydraulic support.

ENGINE - Td4, Intake and exhaust camshafts, Right engine hydraulic mount.

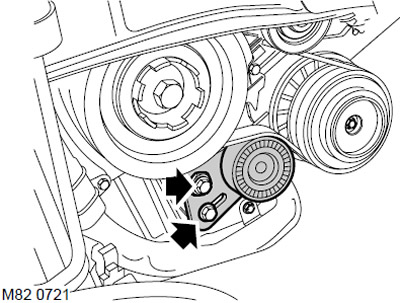

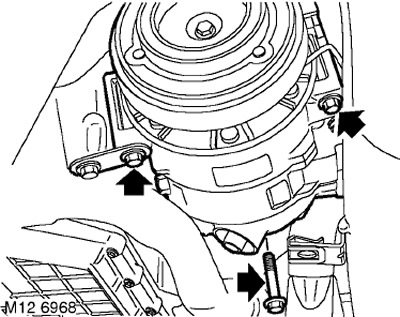

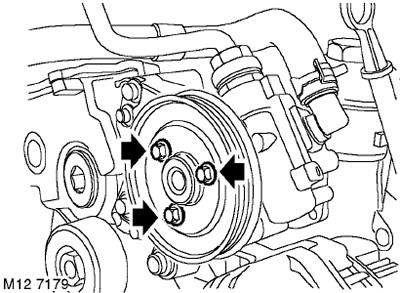

48. Loosen the three bolts securing the power steering pump pulley.

49. Install tool LRT-12-163 onto the accessory drive belt tensioner pulley nut. Turn the tensioner pulley counterclockwise to loosen the belt tension and remove the belt.

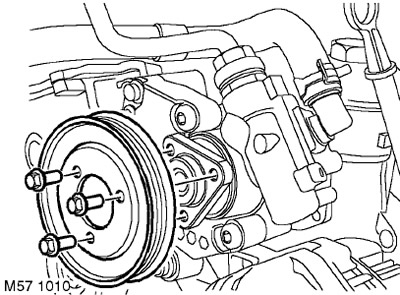

50. Turn out bolts and remove a pulley of the pump of the hydraulic booster.

51. Turn away 4 bolts of fastening of the pump of the hydraulic booster of a steering, take away the pump and fix it.

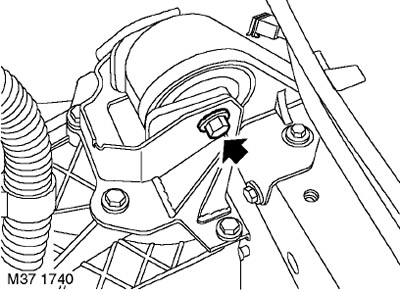

52. Turn out a through bolt of fastening of the left support of the engine to a transmission.

53. With the help of a partner, bypassing obstacles, lower the engine with the gearbox to the floor.

54. Remove the silent block from the support.

Installation

1. Attach the LRT-12-138 adjustable head hoist to the motor.

2. Install the silent blocks on the support.

3. Raise the engine with the gearbox, move the gearbox bracket to the installation site.

4. Pass the through bolt of the gearbox bracket into the support on the body and tighten the bolt to 100 Nm.

5. Install the power steering pump. Tighten the M8 screws to 24 Nm and the M6 screws to 10 Nm.

6. Put on the power steering pump pulley and align the bolt holes with the threaded sockets. Check that the label "FRONT" was turned outward. Tighten the bolts with your fingers.

7. Use the LRT-12-163 tool to retract the tensioner roller and, with the help of a partner, put on the belt. Check that the belt is in the correct position in the pulley grooves.

8. Tighten the pump drive pulley bolts to 10 Nm.

9. Install the hydraulic support.

ENGINE - Td4, Intake and exhaust camshafts, Right engine hydraulic mount.

10. Lower the chains, unhook and remove the LRT-12-138 yoke.

11. Establish a reception pipe of system of release.

MANIFOLDS AND EXHAUST SYSTEM - Td4, REPAIR WORK, Downpipe.

12. Install the cardan shaft on the transfer box drive flange so that the previously applied marks are aligned. Tighten nuts and bolts to 40 Nm.

13. Reinstall the rear beam.

FRONT SUSPENSION, REPAIR WORKS, Front subframe.

14. Wipe the ends of the drive shaft and the places of its installation in the hub and in the differential.

15. With the help of a partner, insert the shafts into the gearbox, holding them at the right angle so as not to damage the gearbox oil seals.

16. Models with air conditioning system: Install the compressor, screw in the bolts and tighten them to a torque of 25 Nm.

17. Air conditioning models: Connect the electrical connector to the compressor.

18. Models with air conditioning system: Install the compressor bracket on the pallet, screw in the bolts and tighten them to a torque of 10 Nm.

19. Models with air conditioning system: Install the lower cooling pipe on the sump, screw in the bolts and tighten them. Tightening torque 10 Nm.

20. Models with A/C system: Check that the compressor drive belt, compressor pulley, crankshaft pulley and rollers are clean.

21. Models with air conditioning system: Install the belt on the compressor pulley.

22. Models with air conditioning system: Tension the compressor drive belt.

AIR CONDITIONING SYSTEM, Air conditioning compressor drive belt - for models with Td4 engine, Air conditioning compressor drive belt - for models with Td4 engine.

23. Connect the cooling system hoses to the flare heater and secure with clamps.

24. Wipe the hoses and fittings of the vacuum reservoir.

25. Attach vacuum hoses to a vacuum receiver.

26. Wipe the hoses and vacuum pump fittings.

27. Attach vacuum hoses and tighten collars.

28. Tighten the bolt securing the hydraulic booster tube to the eye to 10 Nm.

29. Connect the heater hoses and secure them with a clamp.

30. Connect and secure the cooling system hoses to the transmission heat exchanger.

31. Attach a hose of system of cooling to a distributive tube and fix it with a collar.

32. Connect the top hose to the radiator and secure with a clamp.

33. Attach the fuel pipes to the clamps on the fuel rail.

34. Put a hose on a radiator of an intercooler of air and fix it with a collar.

35. Attach the multi-position connectors to the gearbox and secure the connectors in the clips on the support.

36. Install the selector lever, attach the selector cable and secure the cable sheath to the bracket.

37. Adjust the selector cable.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Selector cable adjustment.

38. Connect the battery cable to the starter retractor and tighten the nut to 13 Nm.

39. Put a wire on the gearbox "masses" and tighten the mounting bolt. Tightening torque 25 Nm.

40. Route the wire harnesses to the junction box and install the grommets.

41. Secure the wire harnesses with clamps and screws.

42. Connect the connectors.

43. Attach 3 multi-position connectors to the automatic transmission control unit.

44. Install the engine control unit (ECM).

ENGINE CONTROL SYSTEM: EDC, REPAIR WORK, Engine control unit (ECM).

45. Fill in the working fluid in the automatic transmission.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Replacement of the working fluid in the box.

46. Fill oil into the transfer case housing to the required level.

TRANSFER BOX, ADJUSTMENTS, Changing the transmission oil in the transfer case: except for the North American market.

47. Replace the battery tray.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Support tray - storage battery.

48. Install intake hoses.

49. Fill the engine with coolant.

COOLING SYSTEM: Td4 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

50. Untie the hood and close it.

51. Attach "negative" battery terminal.

Comments on this article