Dismantling

1. Remove the timing cover gasket.

ENGINE - Td4, Intake and exhaust camshafts, Timing gear cover gasket.

2. Take out a back epiploon of a cranked shaft.

ENGINE - Td4, Intake and exhaust camshafts, Replacing the crankshaft rear oil seal.

3. Remove connecting rod bearings.

ENGINE - Td4, Piston group, Replacement of connecting rod bearings.

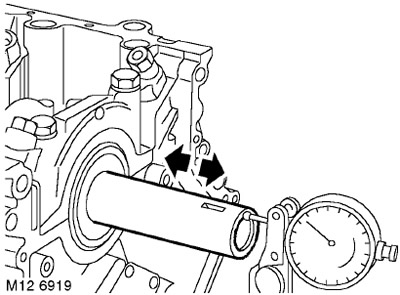

4. To measure the end play of the crankshaft, set the dial indicator as shown in the figure, move the crankshaft back and set "zero" indicator. Advance the crankshaft in the opposite direction and take the reading of the indicator.

TECHNICAL DATA, Engine - Diesel Td4.

5. Remove the 10 bolts securing the main covers to the cylinder block and save them for later use.

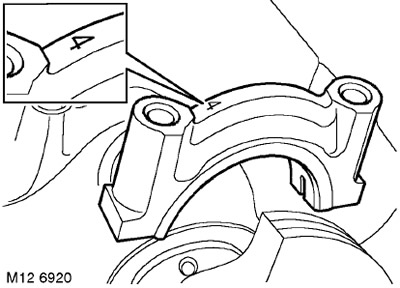

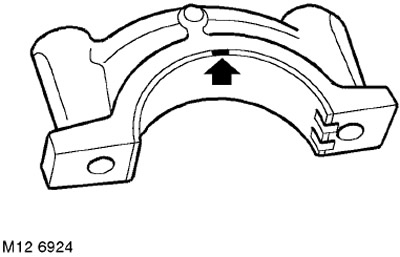

6. Carefully remove the main caps, remembering that the No. 4 cap has a flared insert. Lay out the main covers in the order they were installed on the engine.

7. Remove the crankshaft from the cylinder block.

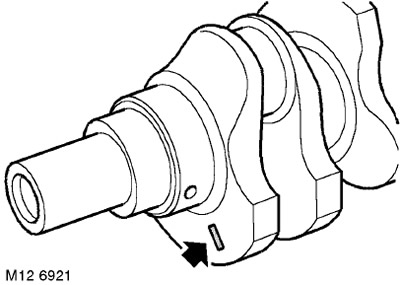

8. Take out loose leaves from the block of cylinders and radical covers and utilize them.

9. Wipe the crankshaft, thoroughly blow out all oil channels.

10. Wipe the main covers and bed liners in the cylinder block, blow dry the sockets of the main bolts.

11. Wipe off the old main bolts and lightly oil their threads.

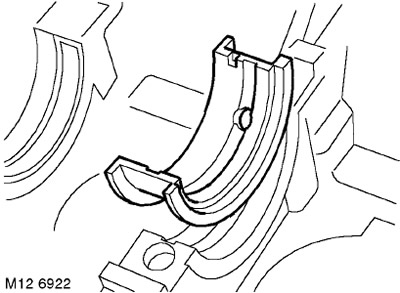

12. The size group of the main journal can be recognized by the colored mark on the front counterweight, if this mark is visible. If the mark could not be found, then measure the diameter of the main journals.

13. Measure the diameter of each main journal in four directions at an angle of 90, record the measurement results, determine the ovality of the journals. Compare measurement results with specifications.

TECHNICAL DATA, Engine - Diesel Td4.

14. If the ovality of the necks of the nominal or 1st repair size is higher than the allowable value, then they can be ground to the next repair size.

15. If the ovality of the necks is within acceptable limits, but the diameter, due to natural wear, is less than that indicated by the color code, then when measuring the gap using a deformable gauge, inserts of increased thickness should be installed in the block and in the covers (within one repair size).

16. Install liners of the selected thickness in the block and in the covers, remembering that there must be an insert with a stop flange in the cover No. 4.

NOTE: Only liners marked with a yellow mark should be installed in the cylinder block. The oil clearance is adjusted by replacing the liners in the main covers. Ignore the colored marks on the cylinder block walls.

17. Lay a cranked shaft in the block of cylinders.

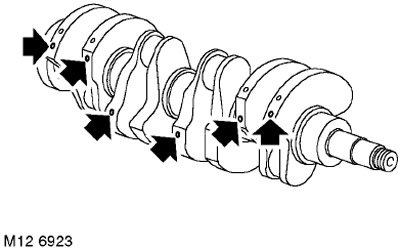

18. Check the color marks on the counterweights of the crankshaft as shown.

19. Insert liners with marks of the same color into the root caps (marks are located on the edge of the liners), bearing in mind that the flare insert is installed in cover No. 4.

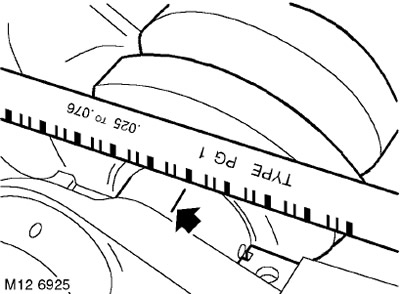

20. Place a deformable gauge strip on the main journal ("plastigage").

21. Install main caps and old main bolts. Tighten the main bolts diagonally

20 Nm, then tighten them by 70°. Recheck the end play of the crankshaft.

ATTENTION: When measuring the clearance with a deformable gauge, do not turn the crankshaft.

22. Consistently loosen and remove the main bolts, remove the main caps and bearings.

23. Using a special ruler, measure the width of the calibration strip and use this value to determine the amount of clearance on each main journal.

TECHNICAL DATA, Engine - Diesel Td4.

24. If the values do not meet the specifications, then you need to choose another insert (And) from the size group and repeat the gap measurement.

25. Remove the crankshaft and remove all traces of calibration strips from the main journals using clean engine oil and a cloth.

26. Install approved liners in the main covers.

27. Lubricate the main journals and approved main bearings with clean engine oil.

28. Install main caps and old main bolts.

29. Tighten the bolts to a torque of 20 Nm, and then tighten them by 70°.

30. Install a dial gauge on the tip end of the crankshaft, slide the crankshaft back and set "zero" indicator.

31. Move the crankshaft forward and read the indicator.

TECHNICAL DATA, Engine - Diesel Td4.

32. If end play is not within specifications, select a thrust pad with a different flare thickness but with the same color code. Inserts are available with three flange thicknesses.

33. Install the selected liners in both the block and the main cover.

34. Install main caps and old main bolts. Tighten the main bolts diagonally

20 Nm, then tighten them by 70°. Recheck the end play of the crankshaft.

TECHNICAL DATA, Engine - Diesel Td4.

35. If the value of the axial play is within acceptable limits, then: Consistently loosen and turn out the main bolts. Dispose of the bolts.

Installation

1. Lightly lubricate the threads of the new main bolts with engine oil and screw them into the cylinder block.

2. Tighten the main bolts diagonally to 20 Nm, then tighten them 70°.

3. Install connecting rod bearings.

ENGINE - Td4, Piston group, Replacement of connecting rod bearings.

4. Install the timing cover gasket.

ENGINE - Td4, Intake and exhaust camshafts, Timing gear cover gasket.

5. Establish a back epiploon of a cranked shaft.

ENGINE - Td4, Intake and exhaust camshafts, Replacing the crankshaft rear oil seal.

Comments on this article