Examination

1. The top plane of the block of cylinders and the bottom of pistons should be pure.

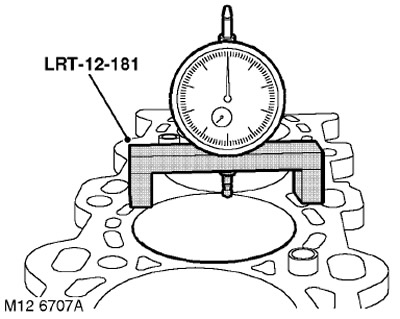

2. Fix the dial indicator in the LRT-12-181 rack and install it on the cylinder block.

3. Expose "zero" indicator.

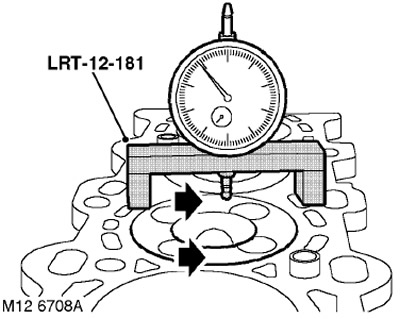

4. Place an indicator on the piston crown and measure the piston protrusion at two points as shown. The TDC position is determined by the largest deviation of the indicator needle when the crankshaft is rocking in both directions. Record the measured piston protrusion and repeat the procedure for all pistons.

5. The largest piston protrusion determines the required thickness of the cylinder head gasket.

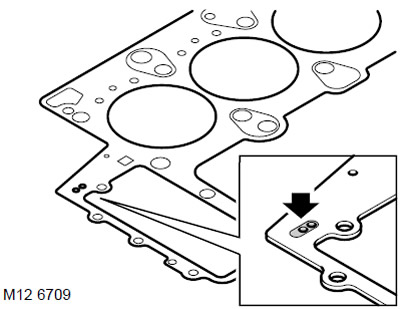

6. When the piston protrudes up to 0.91 mm, a gasket with one notch is installed.

7. When the piston protrudes from 0.91 mm to 1.03 mm, a gasket with two notches is installed.

8. When the piston protrusion exceeds 1.03 mm, a gasket with three notches is installed.

Comments on this article