Dismantling

1. Disconnect "negative" battery terminal.

2. Fix a cowl in vertical position.

3. Drain the engine coolant.

COOLING SYSTEM: MOD. K, KV6 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

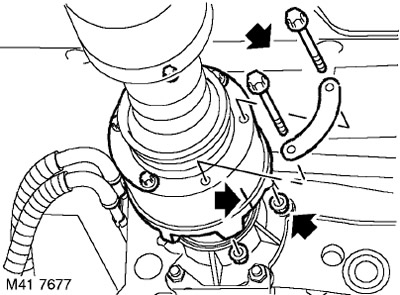

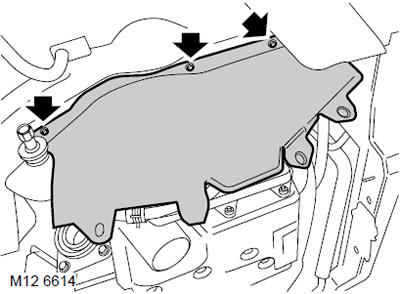

4. Remove a noise-insulating casing of the engine.

KV6 ENGINE - MODIFICATION K, Camshafts of the left cylinder head, Noise-insulating casing of the engine.

5. Remove the battery pad.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Support tray - storage battery.

6. Remove the engine control unit (ECM).

ENGINE MANAGEMENT SYSTEM: SIEMENS, REPAIR WORK, Engine control unit (ECM): except for the North American market.

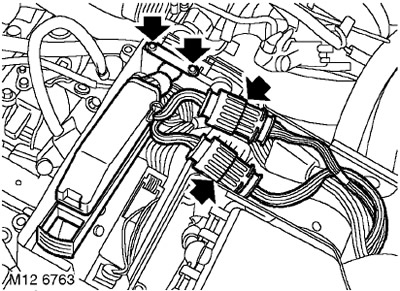

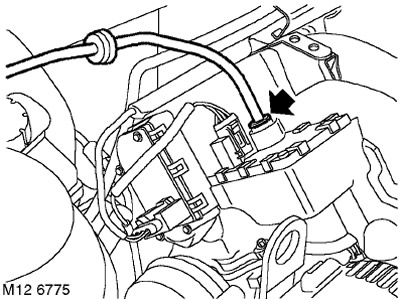

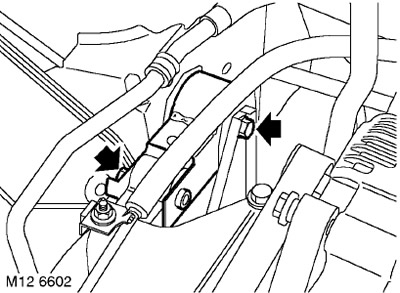

7. Turn away 2 bolts of fastening of a clamping level of a wire plait and remove a level.

8. Disconnect the 2 engine harnesses from the main harness connectors.

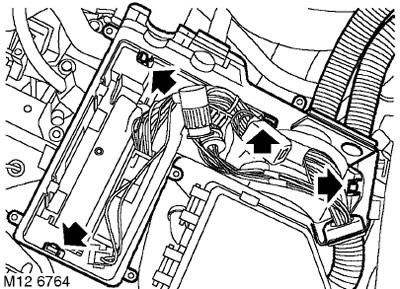

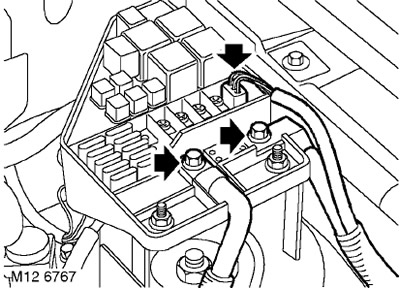

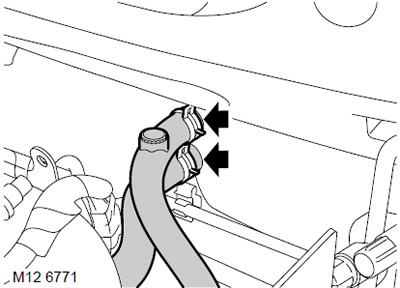

9. Remove the air sleeve and rubber boot from the junction box for routing the harness.

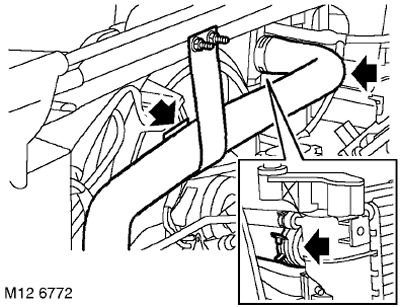

10. Unfasten the 4 latches securing the platform to the back box, remove the platform and place it aside.

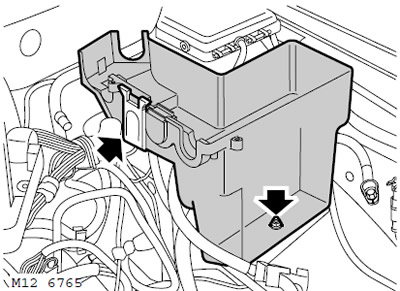

11. Turn away a nut, release a clamp and take out an installation box.

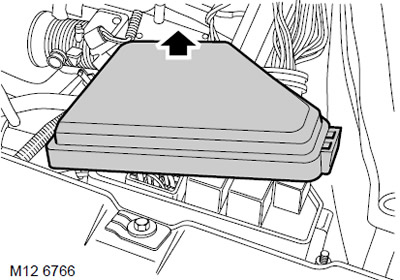

12. Remove the fuse block cover in the engine compartment.

13. Turn away 2 bolts of fastening of tires of the accumulator battery and a starter to the block of safety locks.

14. Disconnect the connector from the fuse box.

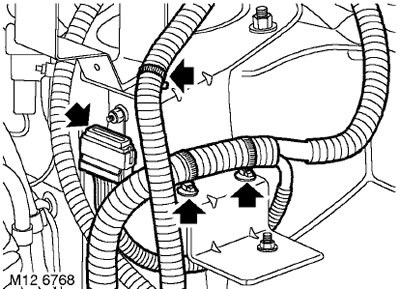

15. Disconnect harness connector "masses".

16. Disconnect the 3 clamps securing the engine harness to the junction box bracket, lay the harness over the engine.

17. Turn away a bolt of fastening of the tire motor "masses".

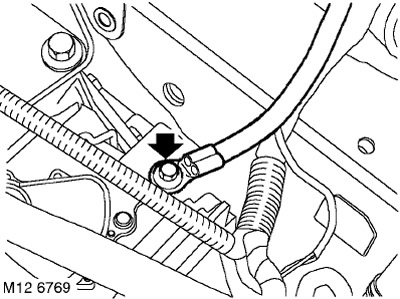

18. Disconnect the connector from the starter retractor.

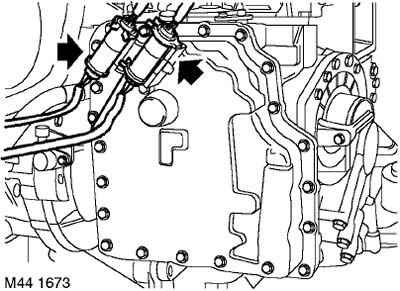

19. Unfasten the two transmission harness connectors and disconnect them.

20. Lay a rag near the fuel supply hose so that spilled fuel does not spread.

CAUTION: Fuel leakage is inevitable during this operation. Take safety precautions to prevent fire or explosion.

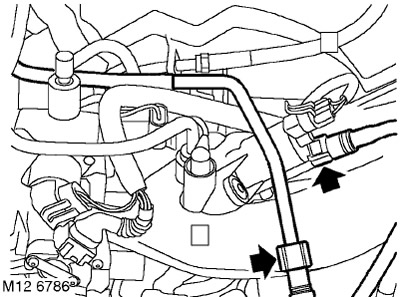

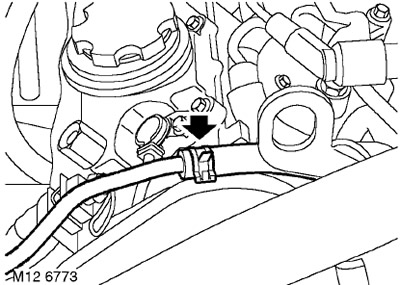

21. Slide back the rubber bushing on the fuel line connector, release the connector and disconnect the supply line from the fuel rail.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

22. Loosen the clamp and disconnect the hose from the canister purge valve.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

23. Release the throttle cable from the clips on the wire harness brackets.

24. Disconnect the cable sheath from the bracket and disconnect the cable from the sector on the throttle pipe (with mechanical damper control).

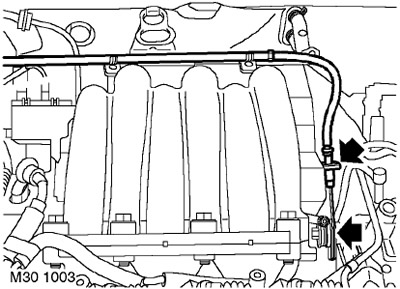

25. Loosen the clamps and remove the heater inlet and outlet hoses.

26. Release the upper radiator hose from the bracket, loosen the clamp and remove the upper hose from the radiator.

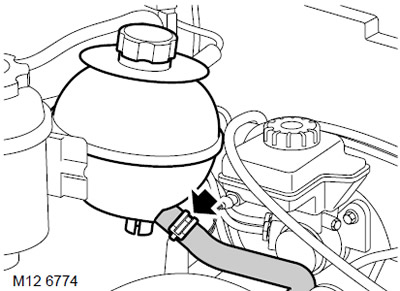

27. Loosen the clamp and disconnect the expansion tank hose from the intake manifold.

28. Loosen the clamp and disconnect the hose from the bottom of the expansion tank.

29. Press the connector shoulders and disconnect the brake booster vacuum hose from the intake manifold reservoir.

30. Raise the car on a lift.

31. Remove the front wheels.

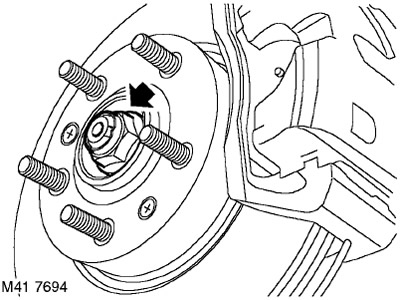

32. Loosen the nut securing the hub to the drive shaft.

33. With the help of a partner holding the brake pedal depressed, unscrew and dispose of the nuts securing the right and left drive shafts to the hubs.

34. Remove a back cross beam.

FRONT SUSPENSION, REPAIR WORKS, Front subframe.

35. Remove a reception pipe of system of release.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Downpipe: except for North American market.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Downpipe: North American market countries.

36. Raise one rear wheel so that the driveshaft can be rotated to gain access to the bolts.

37. To facilitate subsequent assembly, mark the position of the viscous coupling in relation to the transfer case flange.

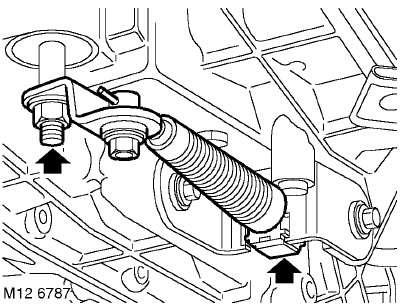

38. Turn away 6 nuts and remove bolts of fastening of a cardan shaft to a leading flange of a distributing box.

39. Remove the propeller shaft from the transfer box drive flange and tie it aside.

CAUTION: Care must be taken when removing the three-roller joint from the transfer case. In order not to damage the cover, it must not be fully stretched, the hinge body must be protected from shock.

40. Drain the gearbox oil.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Replacement of the working fluid in the box.

41. Drain the oil from the transfer case.

TRANSFER BOX, ADJUSTMENTS, Changing the transmission oil in the transfer case: except for the North American market.

TRANSFER BOX, ADJUSTMENTS, Transfer case oil change: North American market countries.

42. Turn away 6 bolts of fastening of the right and left antisplash panels and remove panels.

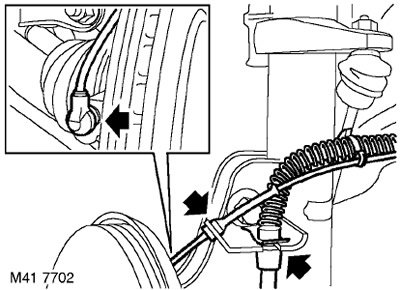

43. Release the brake mounts from the brackets of the right and left shock absorbers.

44. Release the wheel speed sensor wiring harness from the clamp.

45. Disconnect the yaw rate sensors from the right and left hubs.

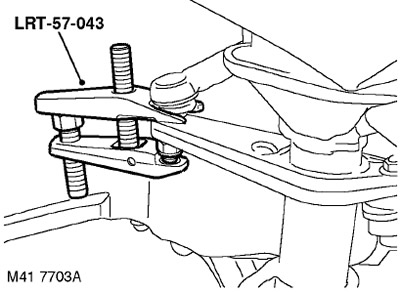

46. Turn away nuts of fastening of the right and left spherical hinges of tips of cross steering draughts to rotary levers.

47. Screw an M12 nut onto each of the ball studs flush with the end of the threaded portion of the stud.

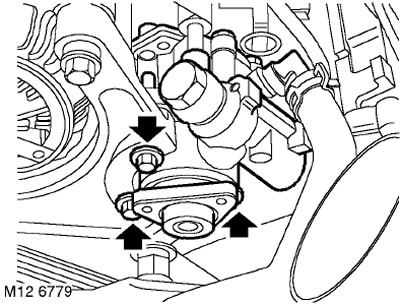

48. Using tool LRT-57-043, separate the ball pins from the right and left steering knuckles. Loosen the M12 nuts and remove the ball pins from the steering knuckles.

49. Move the right and left hubs outward and release the drive shafts from the hubs.

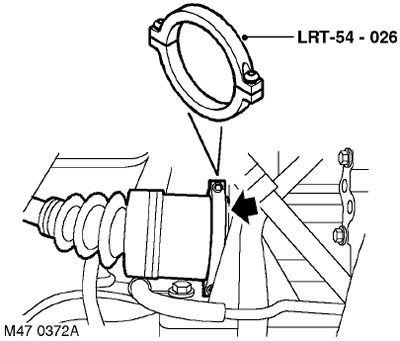

50. Using tool LRT-54-026, remove the drive shafts from the transfer case and from the gearbox.

51. Turn away a nut of fastening of the lever of the selector to a shaft of the selector of a transmission and remove the selector lever from a shaft.

52. Disconnect the selector cable attachment to the gearbox bracket, remove the cable and secure it to the side

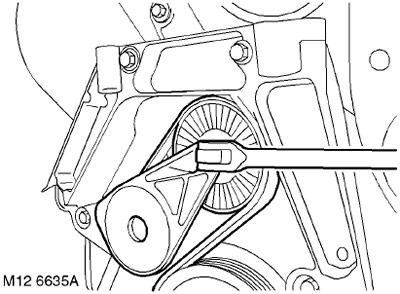

53. Ratchet 3/8" Release the belt tensioner and remove the belt from the A/C compressor pulley.

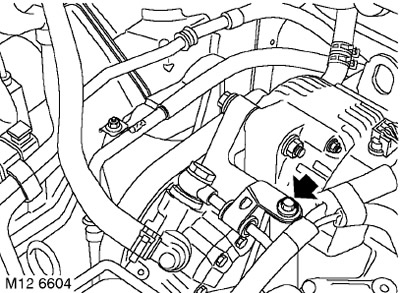

54. Disconnect the connector from the compressor of the cooling system.

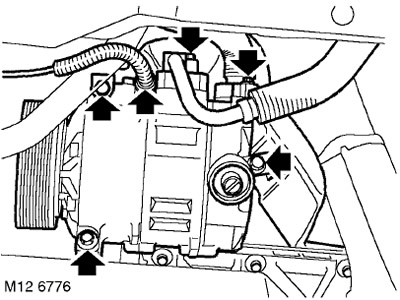

55. Mark the position of the heat shield on the air conditioning compressor, unscrew the 3 compressor mounting bolts from the front plate and from the cylinder block. Remove the cooling system compressor with heat shield and take them aside.

56. Lower the car lift.

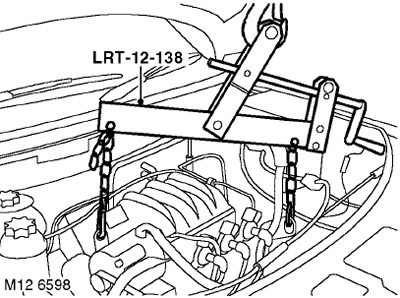

57. Attach the LRT-12-138 adjustable yoke hoist to the engine.

58. Raise the hoist to relieve the engine mounts.

59. Turn out a through bolt of fastening of the left support of the engine to a transmission.

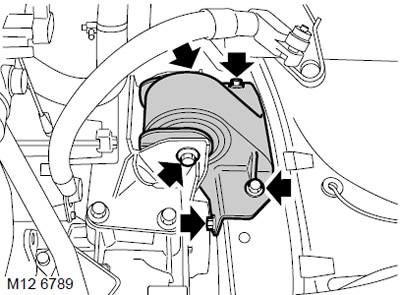

60. Turn out 4 screws of fastening of the left support to a body and remove a support.

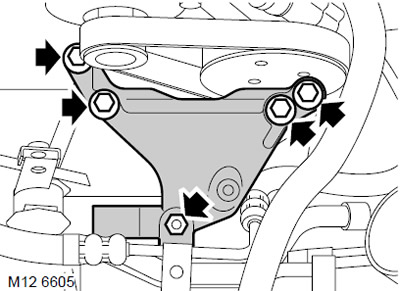

61. Turn out 4 bolts of fastening of the left arm of a support to a transmission and remove an arm.

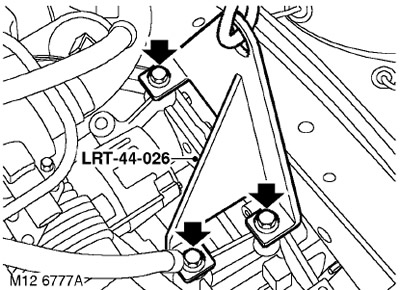

62. Fasten the lifting eyes LRT-44-026 to the gearbox on the gearbox using the bolts of the gearbox brackets.

63. Place a wooden block on the jack, place the jack with the block under the gearbox and raise the jack just enough to bear the weight of the gearbox. Disconnect the hook chain from the rear eye on the engine and hook it onto the eye on the gearbox.

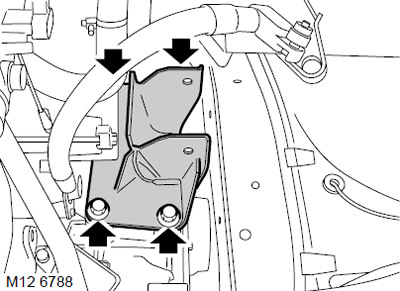

64. Turn out a bolt of fastening of the top right cross-beam of the engine to the top bracket.

65. Loosen the bolt securing the upper right engine cross member to the body and move the cross member away from the upper bracket.

66. Turn away a bolt of fastening of a tube of the pump of the hydraulic booster to a forward plate of the engine.

67. Remove the nut and 4 bolts securing the engine top bracket to the right hydraulic mount and to the front engine mount.

68. Remove the power steering pump tube bracket from the hydraulic support and move the tube aside.

69. Remove the top bracket.

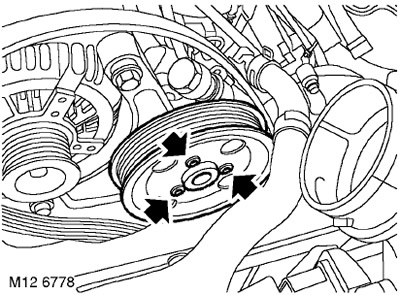

70. Turn away 3 bolts of fastening of a pulley of the pump of the hydraulic booster and remove a pulley.

71. Turn away 3 bolts of fastening of the pump of the hydraulic booster of a steering to a forward plate, take away the pump and fix it.

72. With the help of a partner, bypassing obstacles, lower the engine with the gearbox to the floor.

Installation

1. With the help of a partner, lift the engine into the engine compartment.

2. Install the power steering pump on the front plate, screw in the bolts and tighten them to a torque of 25 Nm.

3. Install the pulley on the power steering pump, screw in the bolts and tighten them to a torque of 9 Nm.

4. Install the upper bracket on the engine and on the right hydraulic support, screw in the bolts and tighten them to a torque of 100 Nm.

5. Install the power steering pump hose bracket on the right hydraulic support, fit the nut and torque tighten it.

6. Place a wooden block on the jack, place the jack with the block under the gearbox and raise the jack just enough to support the weight of the gearbox. Unhook the chain from the eye on the gearbox and hook it to the rear eye on the engine.

7. Lower the jack under the transmission and remove the jack.

8. Turn out bolts of fastening of a lifting eye LRT-44-026 to a transmission and remove an eye.

9. Establish the left arm on a transmission, screw in bolts and tighten them the moment of 85 Nanometers.

10. Establish the left support on a body, screw in bolts and tighten the moment of 48 Nm.

11. Move the gearbox bracket to the left support, thread through the through bolt and tighten it to 100 Nm.

12. Install the upper right cross member on the bracket, screw in the bolt and tighten it to 100 Nm.

13. Tighten the bolt securing the upper cross member to the body to 100 Nm.

14. Install the hydraulic booster pump on the engine front plate, screw in the bolt and tighten it to 25 Nm.

15. Lower the chains, unhook and remove the LRT-12-138 yoke.

16. Raise the car on a lift.

17. Install the cooling system compressor on the front plate of the engine and on the cylinder block, align the holes in the heat shield, screw in the bolts and tighten them to a torque of 25 Nm.

18. Connect the electrical connector to the air conditioning compressor.

19. Ratchet 3/8" remove the tensioner and put the belt on the pulleys of the mounted units.

20. Establish a cover of a cable on a bracket of a transmission and fix a clamp.

21. Install the selector lever on the selector shaft, fit the nut and tighten it to 25 Nm.

22. Wipe the splines on the ends of the drive shafts and their seats in the front hubs.

23. Establish new lock rings on splines of internal hinges of the right and left power shaft.

24. Insert the drive shafts into the transfer case and into the transmission, checking that the retaining rings of each shaft fit into their sockets.

25. Insert the right and left drive shafts into the front hubs.

26. Fit new driveshaft nuts, but do not fully tighten them at this stage.

27. Clean the conical surfaces of the ball pins and the nest for their installation from dirt.

28. Connect the right and left tie rod ends to the steering knuckles, fit new nuts and tighten them to a torque of 55 Nm.

29. Wipe the wheel speed sensors and mating surfaces.

30. Apply anti-seize grease to both sensors and install them in the front hubs.

Check that the sensor is fully inserted into the hub and touches the inductive toothed ring.

31. Install the brake hoses of the right and left wheels on the shock absorber brackets and secure with clamps.

32. Install the left and right mudguards, screw in and tighten the mounting bolts.

33. Check that the mating surfaces of the propeller shaft flange and rear axle drive shaft flange are clean.

34. Install the propeller shaft on the transfer case drive flange so that the previously applied marks line up. Tighten nuts and bolts to 42 Nm.

35. Reinstall the rear beam.

FRONT SUSPENSION, REPAIR WORKS, Front subframe.

36. Fill oil into the transfer case housing to the required level.

TRANSFER BOX, ADJUSTMENTS, Changing the transmission oil in the transfer case: except for the North American market.

TRANSFER BOX, ADJUSTMENTS, Transfer case oil change: North American market countries.

37. Establish a reception pipe of system of release.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Downpipe: except for North American market.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Downpipe: North American market countries.

38. With the brake pedal pressed by the assistant, tighten the nuts of the front hubs to 400 Nm.

39. Lock the nut on the end of the drive shaft.

40. Install the front wheels, screw on the nuts and tighten them to a torque of 115 Nm.

41. Lower the car lift.

42. Attach a hose of the vacuum amplifier of a brake system to an inlet receiver.

43. Attach the cooling system hose to the bottom of the expansion tank and secure it with a clamp.

44. Attach the expansion tank hose to the intake manifold and secure it with a clamp.

45. Connect the top hose to the radiator and secure with a clamp. Fasten the hose to the clamp.

46. Connect the heater inlet and outlet hoses and secure them with a clamp.

47. Attach the throttle control cable to the gas sector and the cable sheath to the bracket (with mechanical throttle control).

48. Attach the throttle control cable to the retainers on the wire harness brackets.

49. Adjust throttle cable (if mechanical control).

FUEL SUPPLY OF PETROL ENGINE, ADJUSTMENTS, Throttle control cable - check and adjustment: KV6 engine.

50. Connect the hose to the canister purge solenoid valve.

51. Attach the fuel line to the fuel rail, slide the rubber bushing over the connection.

52. Attach the multi-position connectors to the gearbox and secure the connectors in the clips on the support.

53. Connect the connector to the starter retractor.

54. Put a wire on the gearbox "masses" and tighten the mounting bolt. Tightening torque 25 Nm.

55. Lay the motor harness on the junction box bracket and secure the harness with a clamp.

56. Connect the harness connector "masses".

57. Connect the connectors to the fuse box in the engine compartment.

58. Connect the battery and starter tires to the fuse box in the engine compartment, screw in the bolts and tighten them to 8 Nm.

59. Reinstall the fuse box cover in the engine compartment.

60. Install the junction box, secure it with a latch, screw on the nut and tighten it with a torque of 9 Nm.

61. Place the platform into the junction box and fasten it with fasteners.

62. Attach the air sleeve and rubber boot for laying the harness to the mounting box and secure them.

63. Connect the engine harness connectors to the main harness.

64. Insert the control system connector into the junction box, install the clamping bar and tighten the clamping bracket screws.

65. Install the engine control unit (ECM).

ENGINE MANAGEMENT SYSTEM: SIEMENS, REPAIR WORK, Engine control unit (ECM): except for the North American market.

66. Replace the battery tray.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Support tray - storage battery.

67. Fill the cooling system with coolant.

COOLING SYSTEM: MOD. K, KV6 engine, ADJUSTMENTS, Coolant drain, system flush and fill.

68. Attach "negative" battery terminal.

69. Fill transmission oil into the gearbox.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Replacement of the working fluid in the box.

70. Reinstall the engine soundproof cover.

KV6 ENGINE - MODIFICATION K, Camshafts of the left cylinder head, Noise-insulating casing of the engine.

Comments on this article