Dismantling

1. Disconnect "negative" battery terminal.

2. Remove the accessory drive belt.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Attachment drive belt - KV6 engine.

3. Remove the right front wheel.

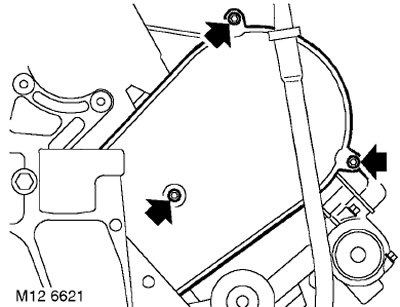

4. Turn away 3 bolts of fastening of the right dirt-protective panel and remove the panel.

5. Turn away 3 bolts of fastening of a cover of a back timing belt on the left head of cylinders and remove a back cover.

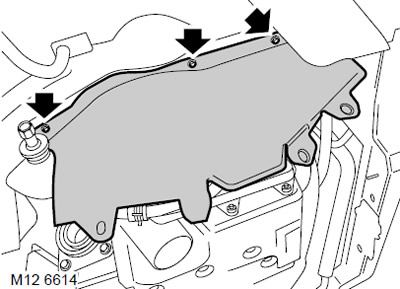

6. Remove the inlet receiver.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Intake reservoir seals: vehicles manufactured before May 2003.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Intake reservoir seals: vehicles manufactured after May 2003.

7. Remove the 2 bolts securing the heat shield to the rear timing belt cover on the right cylinder head and remove the shield.

8. Turn away 3 bolts of fastening of a cover of a back timing belt on the right head of cylinders and remove a cover.

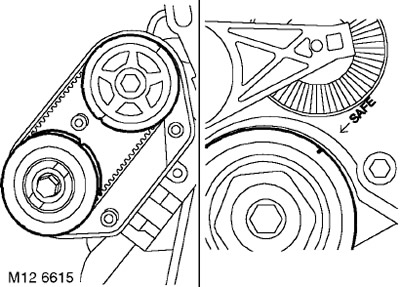

9. Turn the crankshaft clockwise using the socket head for the pulley mounting bolt. Align Risk "SAFE" on the crankshaft pulley with a mark "ARROW" on the engine front plate, with the marks on the rear camshaft gears aligned as shown.

ATTENTION: It is forbidden to turn the engine by the camshaft gear bolts or by the timing belt.

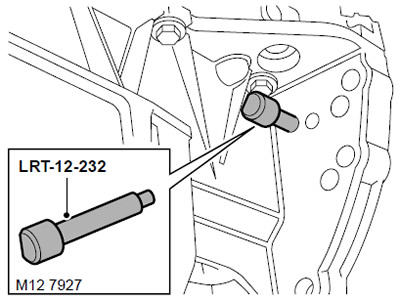

10. Insert the LRT-12-232 pin through the bottom pan hole so that the pin fits into the hole in the drive plate.

CAUTION: The pin is inserted through the bottom tray hole closest to the edge of the tray, as shown.

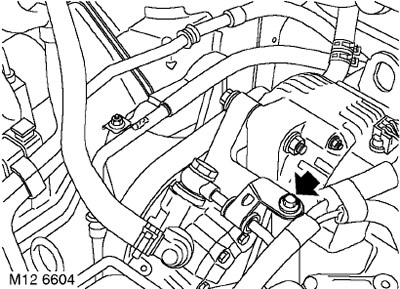

11. Turn away a bolt of fastening of a tube of the pump of the hydraulic booster to a forward plate of the engine.

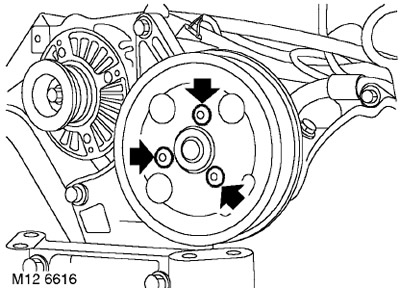

12. Turn away 3 bolts of fastening of a pulley of the pump of the hydraulic booster and remove a pulley.

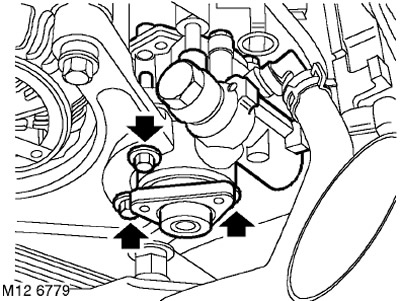

13. Turn away 3 bolts of fastening of the pump of the hydraulic booster of a steering to a forward plate, take away the pump and fix it.

14. Remove the cover from "positive" generator outlet, unscrew the nut and disconnect the battery bus from the generator.

15. Disconnect block from the generator.

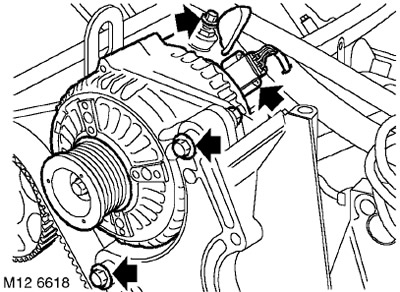

16. Turn away the bottom bolt and the top bolt with a nut of fastening of the generator to a forward plate of the engine.

17. Remove the generator.

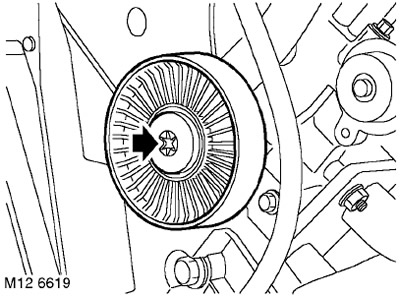

18. Turn away a bolt of fastening of an intermediate roller to a forward plate of the engine and remove a roller.

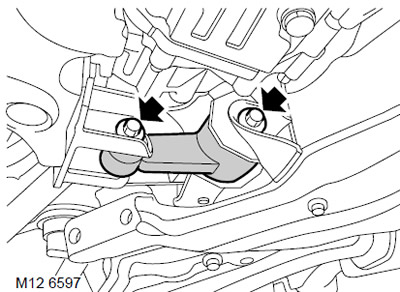

19. Loosen the bolt securing the lower cross member of the engine mount to the subframe.

20. Turn away a bolt of fastening of the bottom crossbeam to a support of the pallet, release the lower crossbeam of the engine from a support of the pallet.

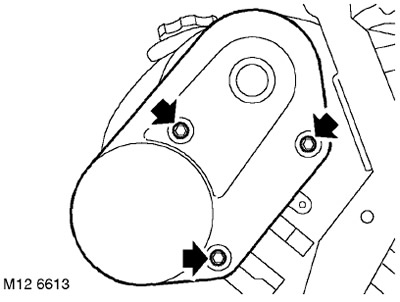

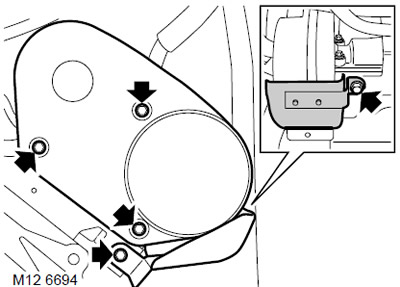

21. Turn away 3 bolts of fastening of a forward cover of a forward timing belt on the right head of cylinders and remove a cover.

22. Turn away 3 bolts of fastening of a forward cover of a forward timing belt on the left head of cylinders and remove a cover.

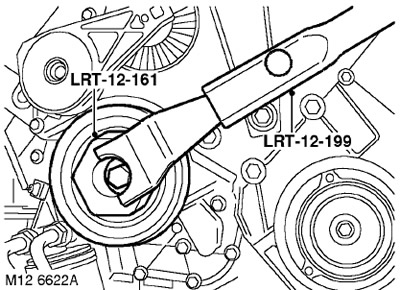

23. Assemble tools LRT-12-161 and LRT-12-199 together by bolting them together.

24. Install tool LRT-12-161 with LRT-12-199 on the crankshaft pulley, loosen and remove the crankshaft pulley bolt.

CAUTION: The crankshaft must not rotate when performing the above procedure.

25. Remove tool LRT-12-161 and LRT-12-199 from crankshaft pulley, remove pulley.

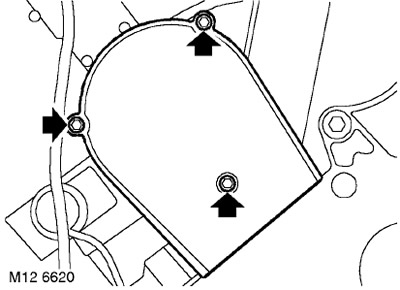

26. Turn away 3 bolts of fastening of the bottom part of a cover of a timing belt to the block of cylinders and remove a cover.

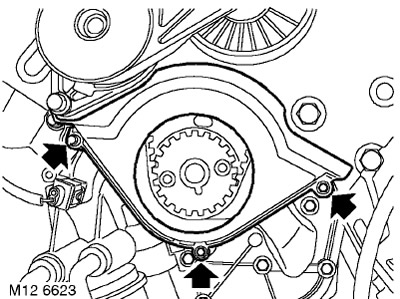

27. Turn away 2 bolts of fastening of a tensioner of a belt of a drive of hinged units and remove a tensioner.

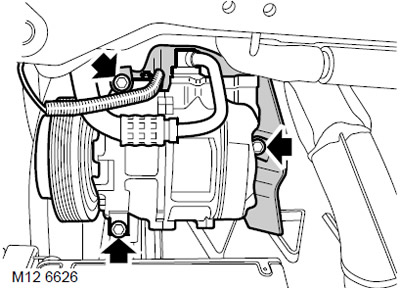

28. Mark the position of the heat shield on the air conditioning compressor, unscrew the 3 compressor mounting bolts from the front plate and from the cylinder block. Remove the cooling system compressor with heat shield and take them aside.

29. Turn away 2 bolts of fastening of a casing of an oil probe to the block of cylinders.

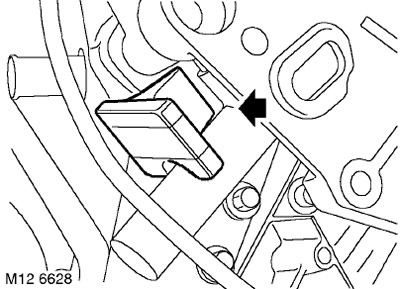

30. While pressing and holding the shoulders of the oil dipstick housing retainer, remove the oil dipstick housing from the sump.

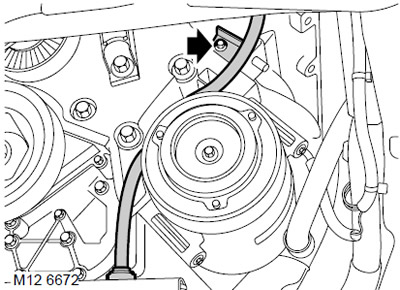

31. Remove the rubber plug located next to the timing belt tensioner.

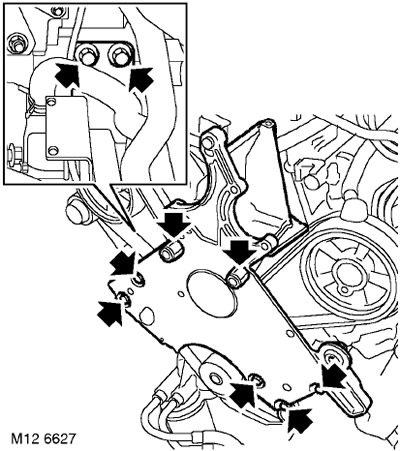

32. Turn away 3 bolts of fastening of a forward plate of the engine and a lifting eye to the block of cylinders.

33. Turn away a bolt of fastening of a lifting eye to the right head of cylinders and remove an eye.

34. Turn away 2 bolts of fastening of an arm of a distributing box to a forward plate of the engine.

35. Turn away 5 bolts and 2 bolts with fastening hairpin.

36. Carefully release and remove the front plate from the engine.

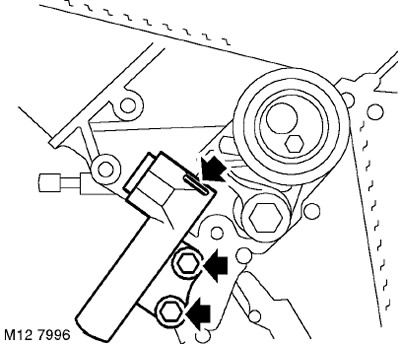

37. Insert a pin with a diameter of 1.5 mm into the hole in the body and the stem of the tension regulator.

NOTE: If the holes in the body and stem do not line up, use a wide-blade screwdriver to move the tensioner lever to push the stem in until the holes line up to allow the pin to be inserted.

38. Turn away and utilize 2 bolts of fastening of a regulator of a tension of a belt to the block of cylinders and remove a regulator.

WARNING: Be very careful not to use too much force when loosening the bolts. If the bolt is difficult to loosen, then you must first moisten it with a lubricant such as "liquid key". DO NOT LOSE the hex socket bolt that secures the idler pulley.

39. If further use of the timing belt is expected, then mark the direction of its movement before removal.

40. Carefully, without the use of tools, release the belt from the gears and remove the belt.

WARNING: Do not rotate the crankshaft with the timing belt removed and the cylinder heads installed.

CAUTION: The timing belt must be replaced if the cylinder head is to be removed, new gears, a new tensioner or coolant pump to be installed. Timing belts require careful handling and storage. Timing belts should be stored on edge and not allowed to have a bend radius of less than 50 mm. Do not use a timing belt that has been twisted or folded in half as the cords may be damaged. Do not use the timing belt if other than dusty wear particles are found on the belt cover (crumbs, thread). Do not use the timing belt if there has been a partial wedging of the engine Belts that have passed 72,000 km must be replaced. Do not use timing belts whose surface is contaminated with oil or coolant. The cause of the contamination must be eliminated.

41. Remove and dispose of the right and left exhaust shaft seals.

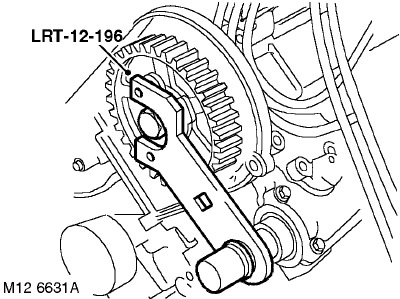

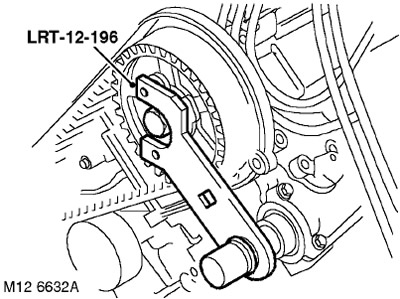

42. Install LRT-12-196 on the intake camshaft gears and on the exhaust camshaft toe.

CAUTION: These mandrels must be installed whenever the gear bolts are tightened or loosened to prevent damage to the camshafts.

43. Loosen and discard the bolts securing the gears to the camshafts.

44. Remove mandrels LRT-12-196 from the intake camshaft gears and from the exhaust camshaft toes.

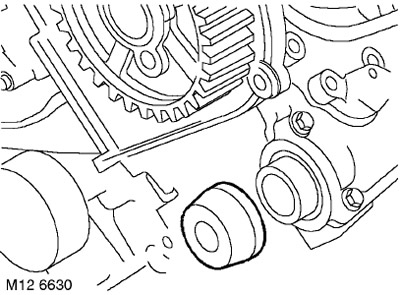

45. Remove the camshaft drive gears with hubs.

Installation

NOTE: It is possible that after replacing the front or rear timing belt and setting the crankshaft pulley to the 'SAFE' position, the position marks on the rear cogwheels will no longer align. Such a mismatch is acceptable provided that the belt replacement procedure was carried out without errors.

1. Wipe the rims of the gears and their hubs, the crankshaft drive gear, the tensioner pulley and the coolant pump pulley.

WARNING: If sintered gears (powder metallurgy technology), have been in contact with oil for a long time, then, before installation, they must be soaked in a solvent and then washed in a pure solvent. The porous structure of the sintered material absorbs oil, which, if released, will contaminate the timing belt.

2. Install the hubs on the gears and install the gears on the camshafts. Screw in new bolts and tighten them enough so that the gear wheels can rotate without dangling.

3. Put the timing belt on the crankshaft gear.

NOTE: To prevent the belt from jumping off the crankshaft gear when putting it on, it must be pressed with an object inserted between the belt and the protective protrusion on the oil pump housing.

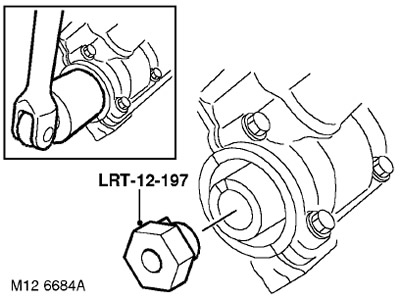

4. Install tool LRT-12-197, in turn, into each of the exhaust camshafts.

5. With the help of a partner, turn the exhaust camshaft slightly until the marks on the right and left rear gears match.

6. Remove tool LRT-12-197 from both exhaust camshafts.

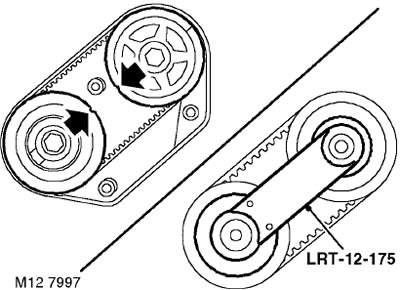

7. Install arbors LRT-12-175 on the left and right rear gears.

8. Turn the front gears on both intake shafts clockwise as you look at the front of the engine.

9. Only with your hands, without the help of any tools, put on the toothed belt, routing it counterclockwise. In doing so, the padded portion of the belt must be kept as taut as possible, the gear wheels turning counterclockwise only as far as the belt can be put on.

WARNING: Gears must not be turned counterclockwise by more than one tooth.

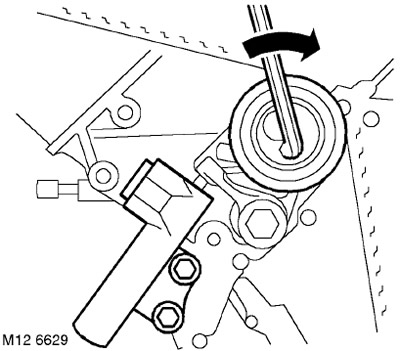

10. Using an L-shaped hex wrench, tension the belt with the tensioner roller.

11. With the help of a partner, install the tensioner, screw in new mounting bolts and tighten them to a torque of 25 Nm.

CAUTION: Check that the tensioner rod touches the tensioner arm.

12. Remove the LRT-12-175 from the rear gears.

13. Install drift LRT-12-196 on both gear wheels of the intake camshafts and on the toe of the exhaust camshafts.

CAUTION: These mandrels must be installed whenever the gear bolts are tightened or loosened to prevent damage to the camshafts.

14. Tighten the front gear bolts:

- Stage 1: 27 Nm

- Step 2: Turn 90°

15. Remove mandrels LRT-12-196 from intake camshaft gears and exhaust camshaft toes.

16. Remove the toothed belt stopper from under the crankshaft gear.

17. Remove the pin from the timing belt tensioner.

18. Insert the rubber plug.

19. Remove pin LRT-12-232.

20. Wipe the exhaust camshaft toe seals and install new seals.

CAUTION: The sealing lips and mating surface must be clean and dry.

21. Install the engine front plate. Install the bolts, but do not completely tighten them.

22. Screw in the bolts securing the transfer case bracket to the engine front plate, but do not completely tighten them.

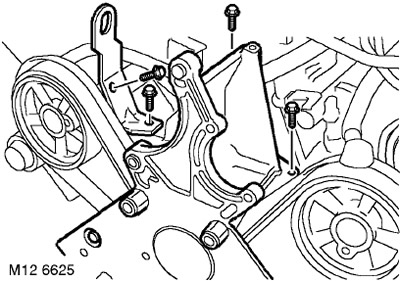

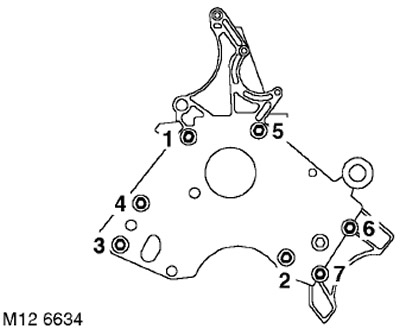

23. Tighten the bolts in the sequence shown in the figure:

- Bolt #1: 25 Nm

- Bolt #5: 45 Nm

- Bolts No. 2, 3, 4, 6 and 7 - 85 Nm

24. Establish a lifting eye on the engine, screw bolts of fastening of a lifting eye and a forward plate of the engine to the block of cylinders and to the right head of cylinders. Tightening torque for M10 bots - 45 Nm, M8 bolts - 25 Nm.

25. Wipe the end of the dipstick housing.

26. Install the dipstick, screw in the bolt and tighten it to 9 Nm.

27. Install the cooling system compressor on the front plate of the engine and on the cylinder block, align the holes in the heat shield, screw in the bolts and tighten them to a torque of 25 Nm.

28. Wipe the bottom of the front timing belt cover.

29. Install the lower timing belt cover and tighten the mounting bolts to 9 Nm.

30. Wipe the crankshaft pulley.

31. Install the crankshaft pulley onto the crankshaft drive gear, making sure that the notch on the pulley is aligned with the lug on the gear.

32. Screw in the pulley mounting bolt with washer, install the LRT-12-161 tool with LRT-12-199 on the crankshaft pulley. Tighten the pulley bolt to 160 Nm.

33. Remove tool LRT-12-161 and LRT-12-199 from crankshaft pulley, remove pulley.

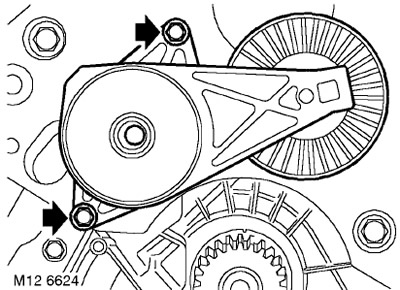

34. Wipe the attachment drive belt tensioner.

35. Install the accessory drive belt tensioner, screw in the bolts and tighten them to a torque of 25 Nm.

36. Wipe the left and right front timing belt covers.

37. Replace the left and right front timing belt covers, screw in the bolts and tighten them to a torque of 4 Nm.

38. Wipe the intermediate roller, install the roller on the engine front plate and tighten the fastening bolt to 45 Nm.

39. Install the generator on the engine front plate.

40. Insert a bolt of fastening of the generator to a forward plate of the engine, get on a nut and tighten the moment of 45 Nanometers.

41. Connect the generator connector.

42. Connect the battery bus to the generator output, fit and tighten the nut to a torque of 8 Nm.

43. Install the power steering pump on the front plate, screw in the bolts and tighten them to a torque of 25 Nm.

44. Install the power steering pump on the engine front plate, screw in the bolt and tighten it to 25 Nm.

45. Wipe the power steering pump pulley and mating surfaces.

46. Install the pulley on the power steering pump, screw in the bolts and tighten them to a torque of 9 Nm.

47. Install the lower cross member on the pallet bracket, screw in the bolts and tighten them to 100 Nm.

48. Tighten the bolt securing the lower cross member to the subframe to 100 Nm.

49. Wipe the cover of the left rear timing belt.

50. Replace the cover of the left rear timing belt, screw in the bolts and tighten them to a torque of 4 Nm.

51. Wipe right rear timing belt cover.

52. Replace the cover of the right rear timing belt, screw in the bolts and tighten them to a torque of 4 Nm.

53. Install the heat shield, screw in the bolts and tighten the M6 bolts to 9 Nm and the M8 bolts to 25 Nm.

54. Install the inlet receiver.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Intake reservoir seals: vehicles manufactured before May 2003.

MANIFOLDS AND EXHAUST SYSTEM: MOD. K, move. V6, REPAIRS, Intake reservoir seals: vehicles manufactured after May 2003.

55. Reinstall the right wheel and tighten the nuts to 115 Nm.

56. Install the accessory drive belt.

SYSTEM OF STARTING THE ENGINE AND CHARGING THE BATTERY, REPAIR WORKS, Attachment drive belt - KV6 engine.

Comments on this article