Dismantling

1. Disconnect "negative" battery terminal.

2. Remove the hydraulic support.

ENGINE - MODIFICATION K, volume 1.8, Front seal of the exhaust camshaft, Right engine hydraulic support.

3. Remove the top part of the timing belt cover.

ENGINE - MODIFICATION K, volume 1.8, Front oil seal of the exhaust camshaft, Upper timing cover.

4. Remove the lower part of the timing belt cover.

ENGINE - MODIFICATION K, volume 1.8, Front exhaust camshaft oil seal, Lower part of the front timing belt cover: vehicles without air conditioning.

5. Temporarily install the pulley on the crankshaft, screw in and lightly tighten the bolt.

6. Turn away bolts of fastening of a latch of a flywheel LRT-12-145 and remove a latch.

7. Rotate the crankshaft until the marks on the camshaft gears align.

WARNING: Do not turn the crankshaft using the camshaft gears, the camshaft bolts or the timing belt.

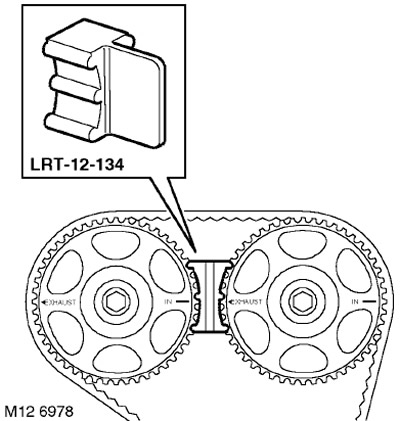

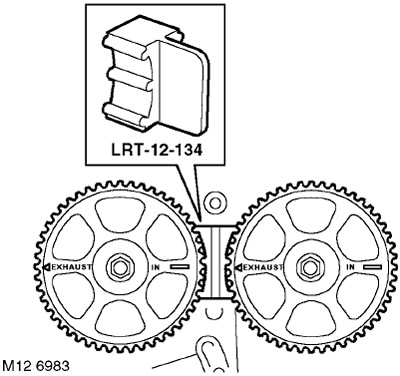

8. Install tool LRT-12-134 to align the camshaft marks.

9. Remove the pulley from the crankshaft.

10. Remove and discard the timing belt tensioner mounting bolt.

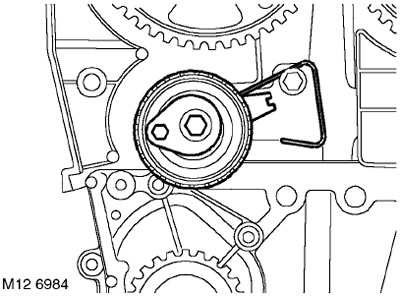

11. Remove the spring indicator along with the timing belt tensioner.

12. If further use of the timing belt is expected, then mark the direction of its movement.

13. Remove the timing belt.

WARNING: When removing the timing belt from the camshaft gears, do not use any tools for this (only with hands). Metal objects can damage the belt and gears. Do not rotate the crankshaft with the timing belt removed and the cylinder head installed. The timing belt should be replaced if the cylinder head is to be removed, new gears, a new tensioner or coolant pump are to be installed. Timing belts must be handled with care. Timing belts should be stored on edge and not allowed to bend more than 50 mm. Do not use a belt that has been twisted or folded in half as the cords may be damaged. Do not use the timing belt if other than dusty wear particles are found on the belt cover (crumbs, thread). Belts that have traveled 72,000 km must be replaced. Do not use timing belts whose surface is contaminated with oil or coolant. The cause of the contamination must be eliminated.

Installation

1. Wipe the crankshaft pinion, camshaft gears, coolant pump wheel and tensioner pulley.

WARNING: If sintered gears (powder metallurgy technology), have been in contact with oil for a long time, then, before installation, they must be soaked in a solvent and then washed in a pure solvent. The porous structure of the sintered material absorbs oil, which, if released, will contaminate the timing belt.

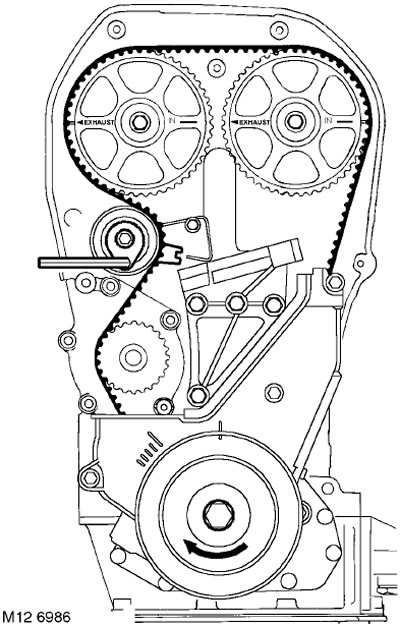

2. Check that the marks on the camshaft gears are aligned and that LRT-12-134 is holding the gears together.

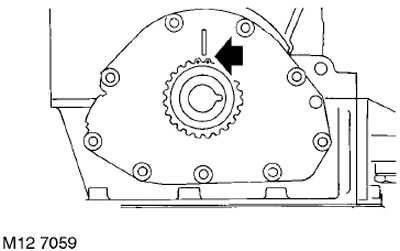

3. Check the position of the marks on the crankshaft drive gear relative to the marks on the oil pump housing (90°to TDC).

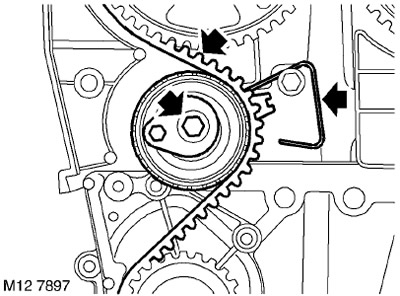

4. Install the spring indicator so that it is higher than the bolt located on the right and that the tensioner lever is in the position "9 o'clock".

5. Screw in a new special one and tighten it so that the tensioner arm can only just be moved.

6. Put on the timing belt without using tools (only with hands). During installation of the belt, its branch between the gears of the intake and exhaust camshafts must remain taut.

ATTENTION: If the old timing belt is used, then the rotation mark must point in the correct direction.

7. Check that the belt is completely on all gears and rollers.

8. Install the lower front timing belt cover.

ENGINE - MODIFICATION K, volume 1.8, Front exhaust camshaft oil seal, Lower part of the front timing belt cover: vehicles without air conditioning.

9. Temporarily install the pulley on the crankshaft, screw in and lightly tighten the bolt.

10. Remove the tool LRT-12-134 to align the camshaft marks.

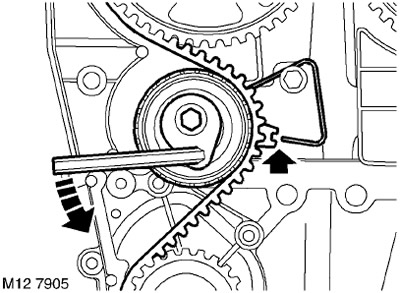

11. Using a 6 mm hex wrench, turn the tensioner counterclockwise so that the notch on the tensioner pointer is opposite the spring indicator.

NOTE: If an old belt is being installed, the spring indicator should be aligned with the bottom of the indicator.

ATTENTION: The tensioner pointer must fit the spring indicator from above. If the tensioner pointer passes the spring indicator, then you need to fully pull the tensioner back and do the operation again.

12. After checking the correct position of the pointer relative to the indicator, tighten the tensioner bolt to 22 Nm.

13. Turn the crankshaft 2 turns until the marks on the camshaft gears are aligned.

WARNING: Do not turn the crankshaft using the camshaft gears, the camshaft bolts or the timing belt.

14. Check the correct position of the tensioner pointer relative to the indicator.

15. If the position needs to be corrected, then loosen the tensioner mounting bolt so that the lever can be moved with great effort. Turn the lever clockwise until tension is completely removed from the belt, then turn the lever clockwise until the pointer is correctly aligned with the indicator.

16. After checking the correct position of the pointer relative to the indicator, tighten the tensioner bolt to 22 Nm.

17. Turn the crankshaft 2 turns until the marks on the camshaft gears are aligned.

18. Check the position of the pointer relative to the indicator, if necessary, repeat the operation described above.

19. Remove the pulley from the crankshaft.

20. Install the LRT-12-145 flywheel stopper on the engine through the starter opening and secure it with two bolts.

21. Install the top of the timing belt cover.

ENGINE - MODIFICATION K, volume 1.8, Front oil seal of the exhaust camshaft, Upper timing cover.

22. Install the hydraulic support.

ENGINE - MODIFICATION K, volume 1.8, Front seal of the exhaust camshaft, Right engine hydraulic support.

23. Attach "negative" battery terminal.

Comments on this article