Dismantling

1. Fix a cowl in vertical position.

2. Disconnect "negative" battery terminal.

3. Remove a noise-insulating casing of the engine.

KV6 ENGINE - MODIFICATION K, Camshafts of the left cylinder head, Noise-insulating casing of the engine.

4. Remove the transfer case (IRD).

TRANSFER BOX, REPAIRS, Transfer case: Models with KV6 engine.

TRANSFER BOX, REPAIRS, Transfer case: Models with KV6 engine.

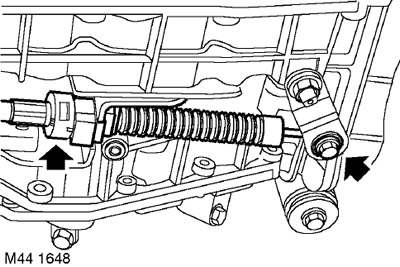

5. Loosen the nut that secures the selector cable to the gear lever.

6. Remove the retainer for fastening the cable sheath to the bracket on the gearbox, remove the cable and the sleeve for fastening the cable on the lever.

7. Turn away 3 bolts of fastening of the left dirt-protective panel and remove the panel.

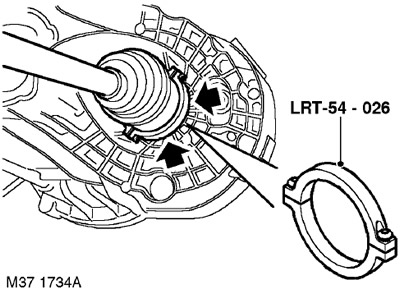

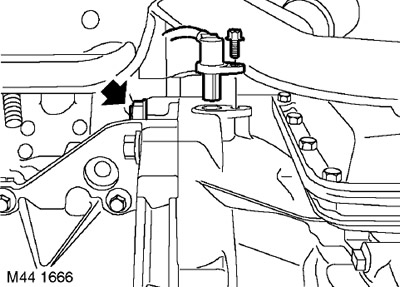

8. Install tool LRT-54-026 on the drive shaft inner joint. Using the lever, release the inner joint from the gearbox.

9. With the help of a partner, move the hub outward and remove the drive shaft from the gearbox.

CAUTION: When removing the drive shaft, be careful not to damage the oil seal.

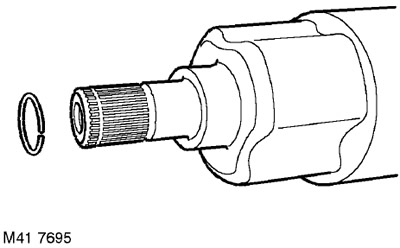

10. Remove and discard the drive shaft retaining ring.

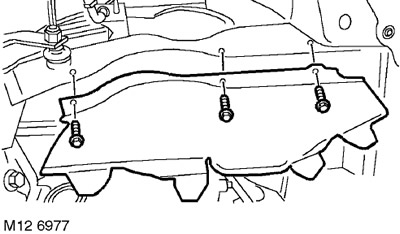

11. Turn out two bolts of fastening of a cover of the hatch of the hydrotransformer.

12. Remove the hatch cover.

13. Mark the mutual position of the drive disk and the torque converter for subsequent assembly.

14. Turn away 4 bolts of fastening of a leading disk to the hydrotransformer.

15. Turn away a bolt of fastening of a bracket of the hose of the system of cooling going on a distributing box. Remove the bracket.

16. Turn away 2 bolts of fastening of a transmission to the engine.

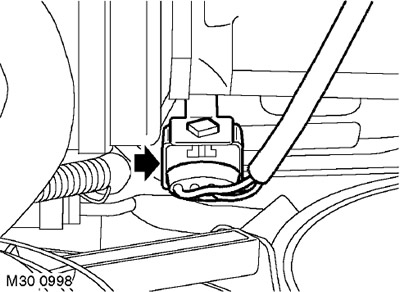

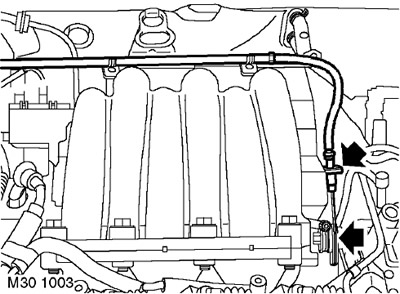

17. Release the oxygen sensor connector from the bracket on the left valve cover, disconnect the connector.

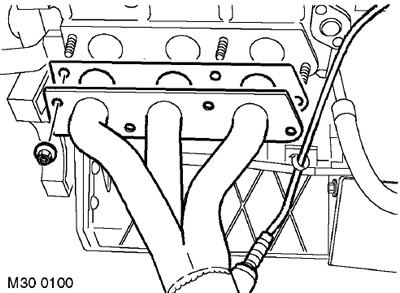

18. Turn away 4 nuts of fastening of the left final collector to a head of cylinders.

19. Remove the exhaust manifold and discard its gaskets.

20. Install a container to collect the escaping fluid.

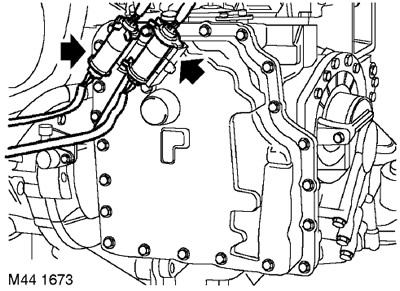

21. Disconnect the 2 fittings from the heat exchanger and discard the O-rings.

CAUTION: Always plug fittings and openings to keep dirt out of the system.

22. Turn away 3 bolts of fastening of an arm of the heat exchanger.

23. Move the heat exchanger to the side.

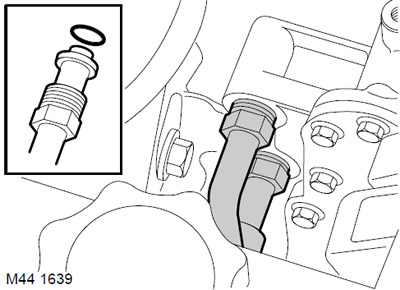

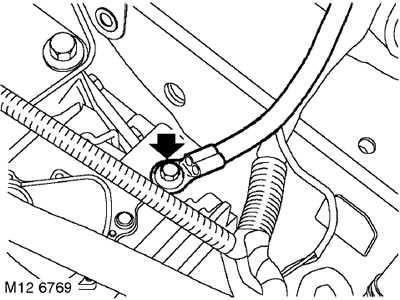

24. Turn away a bolt of fastening of the gauge of position of a cranked shaft to a transmission, release the gauge and take it aside.

25. Turn away a bolt with a nut of fastening of a transmission to the engine, located near the crankshaft position sensor.

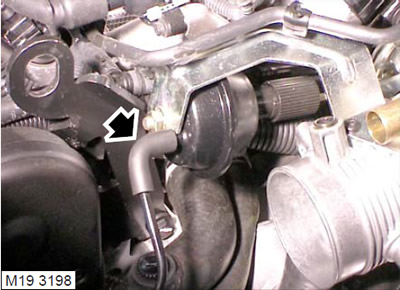

26. Disconnect the cable sheath from the bracket and disconnect the cable from the sector on the throttle pipe (with mechanical damper control).

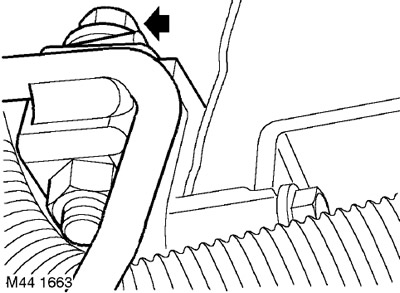

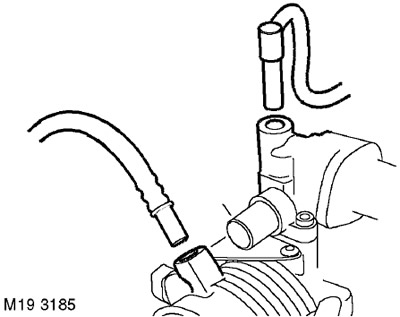

27. Squeeze the shoulders and disconnect the 2 ventilation tubes from the throttle (with ventilation pipes).

28. Vehicles with cruise control: Disconnect the vacuum hose from the cruise control actuator.

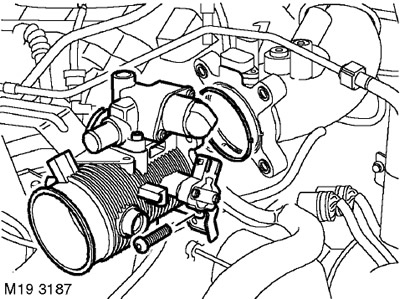

29. Turn away 4 bolts of fastening of a throttle branch pipe, remove a throttle branch pipe and take it aside.

Throttle pipe shown for vehicles other than North American market.

30. Remove the O-ring from the orifice and discard.

31. Remove the starter.

SYSTEM OF ENGINE START AND CHARGING OF AKB, REPAIR WORKS, Starter - engine KV6.

32. Turn away a bolt of fastening of the tire motor "masses".

33. Release the connectors from the spring clips on the bottom of the box.

34. Disconnect the 2 transmission harnesses from the main engine harness connectors.

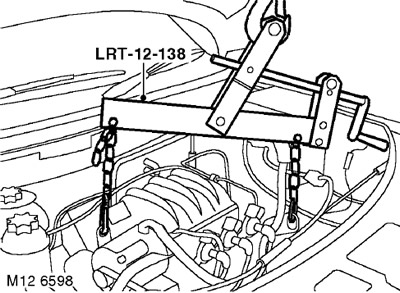

35. Attach the LRT-12-138 adjustable yoke hoist to the engine.

36. Raise the hoist to relieve the engine mounts.

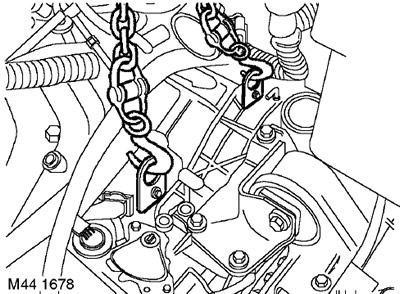

37. Attach lifting eyes to the gearbox.

38. Attach rigging to the eyelets.

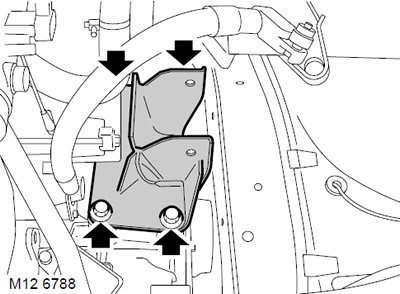

39. Turn out a through bolt of fastening of the left support of the engine to a transmission.

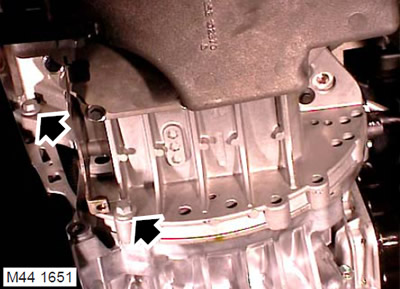

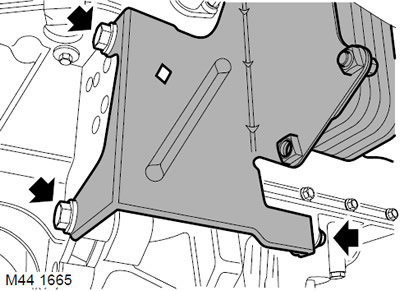

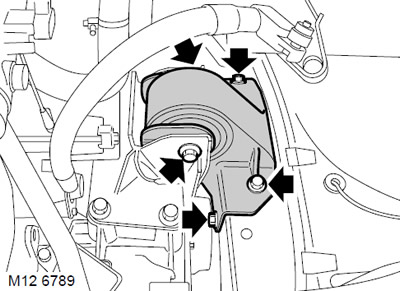

40. Turn out 4 screws of fastening of the left support to a body and remove a support.

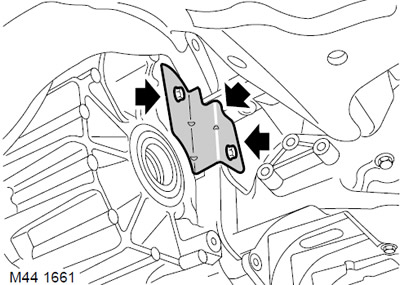

41. Turn out 4 bolts of fastening of the left arm of a support to a transmission and remove an arm.

42. Remove the 2 upper bolts securing the gearbox to the engine.

43. Release the gearbox from the two guide pins.

44. Lower the gearbox to the floor.

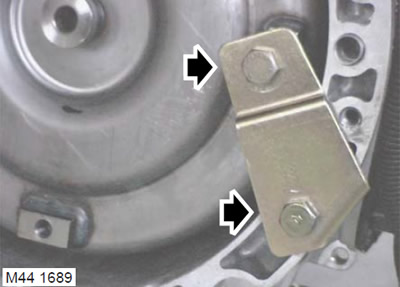

45. Install the torque converter fixing plate and secure it with screws.

Installation

1. Remove the torque converter fixing plate.

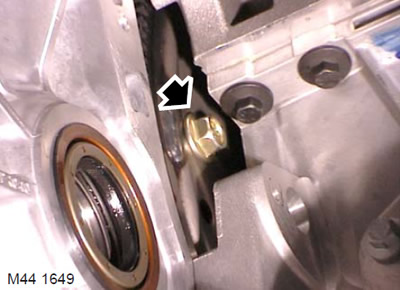

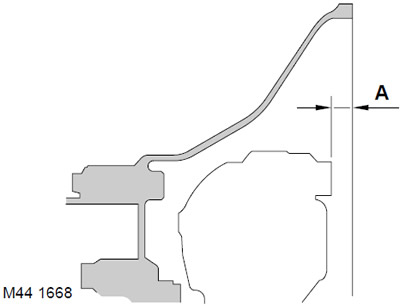

2. Check that the torque converter is fully seated on the oil pump drive by measuring dimension 'A' shown in the figure. Dimension A = 4 mm.

3. Wipe the mating surfaces of the engine and gearbox, dowel pins and pin sockets.

4. Install the gearbox.

5. Screw in bolts of fastening of a transmission to the engine and tighten them the moment of 85 Nm.

6. Establish the left arm on a transmission, screw in bolts and tighten them the moment of 85 Nanometers.

7. Establish the left support on a body, screw in bolts and tighten the moment of 48 Nm.

8. Move the gearbox bracket to the left support, thread through the through bolt and tighten it to 100 Nm.

9. Remove lifting chains.

10. Turn away bolts with nuts by which eyelets fasten to a transmission and remove eyelets.

11. Attach the connectors to the main harness.

12. Secure the connectors in the spring clips.

13. Install the tire "masses" engine and secure it with a bolt.

14. Reinstall the starter.

SYSTEM OF ENGINE START AND CHARGING OF AKB, REPAIR WORKS, Starter - engine KV6.

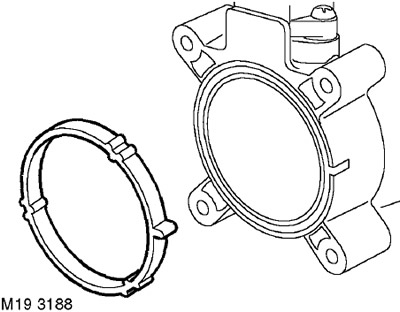

15. Wipe the mating surfaces of the throttle tube and inlet receiver.

16. Install a new gasket on the inlet reservoir.

17. Establish a throttle branch pipe on an inlet receiver, screw in bolts and tighten them with the moment of 7 Nm.

18. Fasten the throttle control cable to the gas sector and the cable sheath to the bracket (with mechanical throttle control).

19. Connect the hose to the cruise control actuator.

20. Connect ventilation hoses (if installed) to the throttle body.

21. Adjust throttle cable (if mechanical control).

FUEL SUPPLY OF PETROL ENGINE, ADJUSTMENTS, Throttle control cable - check and adjustment: KV6 engine.

22. Wipe the crankshaft position sensor (CKP) and mating surfaces.

23. Install the crankshaft position sensor, screw in its mounting bolt and tighten to 9 Nm.

24. Install the heat exchanger, tighten the M12 bolts to 85 Nm, the M8 bolts to 25 Nm.

25. Wipe the heat exchanger fittings.

26. Lubricate new O-rings with clean working fluid and install them on the heat exchanger hoses.

FILLING CAPACITIES, LIQUIDS AND OILS, Lubrication system.

27. Connect the heat exchanger hoses to the gearbox and tighten the union nuts to a torque of 18 Nm.

28. Wipe the exhaust manifold and mating surface on the cylinder head.

29. Install the exhaust manifold gasket.

30. Install the exhaust manifold, fit the nuts and tighten them to a torque of 45 Nm, starting from the center.

31. Connect the oxygen sensor connector and secure it to the bracket.

32. Install the transfer box heat exchanger hose clamp, screw in the mounting bolt and tighten it to 25 Nm.

33. Align the position marks of the drive disc and the torque converter.

34. Screw in the bolts securing the drive disc to the torque converter and tighten them to a torque of 45 Nm.

35. Wipe the cover of the torque converter hatch.

36. Install the hatch cover, screw in the bolts and tighten them to a torque of 9 Nm.

37. Wipe the spline of the drive shaft and mating splines in the gearbox.

38. Install a new retaining ring on the end of the left drive shaft.

39. With the help of a partner, move the hub outward and insert the drive shaft into the gearbox, being careful not to damage the shaft seal.

CAUTION: Push down on the drive shaft to make sure the retaining ring is seated in its groove and holds the shaft.

40. Install the mudguard panel and secure it with bolts.

41. Install the cable sleeve on the selector lever, thread the cable through the hole in the sleeve, but do not tighten the nut at this stage.

42. Establish a cover of a cable on a bracket of a transmission and fix a clamp.

43. Adjust the selector cable.

AUTOMATIC TRANSMISSION: JATCO, ADJUSTMENTS, Selector cable adjustment.

44. Install the transfer case (IRD).

TRANSFER BOX, REPAIRS, Transfer case: Models with KV6 engine.

45. Attach "negative" battery terminal.

46. Reinstall the engine soundproof cover.

KV6 ENGINE - MODIFICATION K, Camshafts of the left cylinder head, Noise-insulating casing of the engine.

47. Untie the hood and close it.

Comments on this article