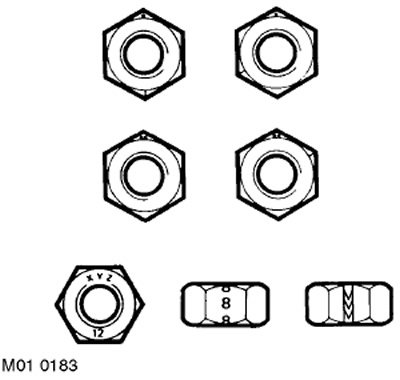

Instead of indicating the strength index, the so-called "hourly" method of specifying the strength index. A mark is applied to the outer chamfer or end of the nut, which corresponds to the readings of the clock hands. Indications "hours" and are the designation of the strength index.

A dot is used to indicate the 12 o'clock mark, and (strength index values) notch is used. If the strength index is greater than 12, then a double dot is used to indicate the 12 o'clock mark.

When tightening "crown" nut with cotter pin slots, never loosen the nut to align the cotter pin holes. An exception is the case when this is provided for by the adjustment instruction. If you can't align the cotter pin holes, try replacing the washer or nut, or sanding the existing washer.

If the bearing preload is adjusted by means of a nut, then the nut must be tightened in accordance with a separate instruction.

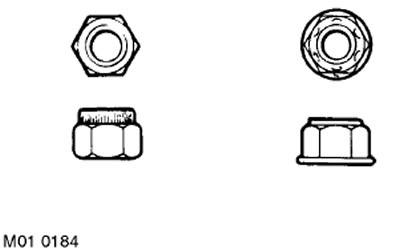

Self-locking nuts

Self-locking nuts (refers to nuts with a nylon insert or nuts with increased thread friction) can be reused, provided that an increase in resistance to screwing is felt at the moment the insertion part of the nut begins to be screwed.

NOT use heat to try to loosen a nut or bolt that is difficult to remove. This not only damages the protective coating, but also creates a risk of damage to electronic equipment and brake pads from excessive heat.

When removing self-locking nuts, it is recommended to replace them with new ones of similar design.

If the bearing preload is adjusted by means of a nut, then the nut must be tightened in accordance with a separate instruction.

Comments on this article